System for treating malodorous gas from sludge

a technology for treating systems and malodorous gas, which is applied in the direction of separation processes, dispersed particle separation, chemical instruments and processes, etc., can solve the problems of affecting the sanitation of the plant area and surrounding areas, affecting the reliability of the adsorber operation, and posing serious safety hazards for field operators, so as to reduce the replacement frequency significantly, ensure the reliability of the adsorber operation, and reduce the cost of energy consumption. to negligible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

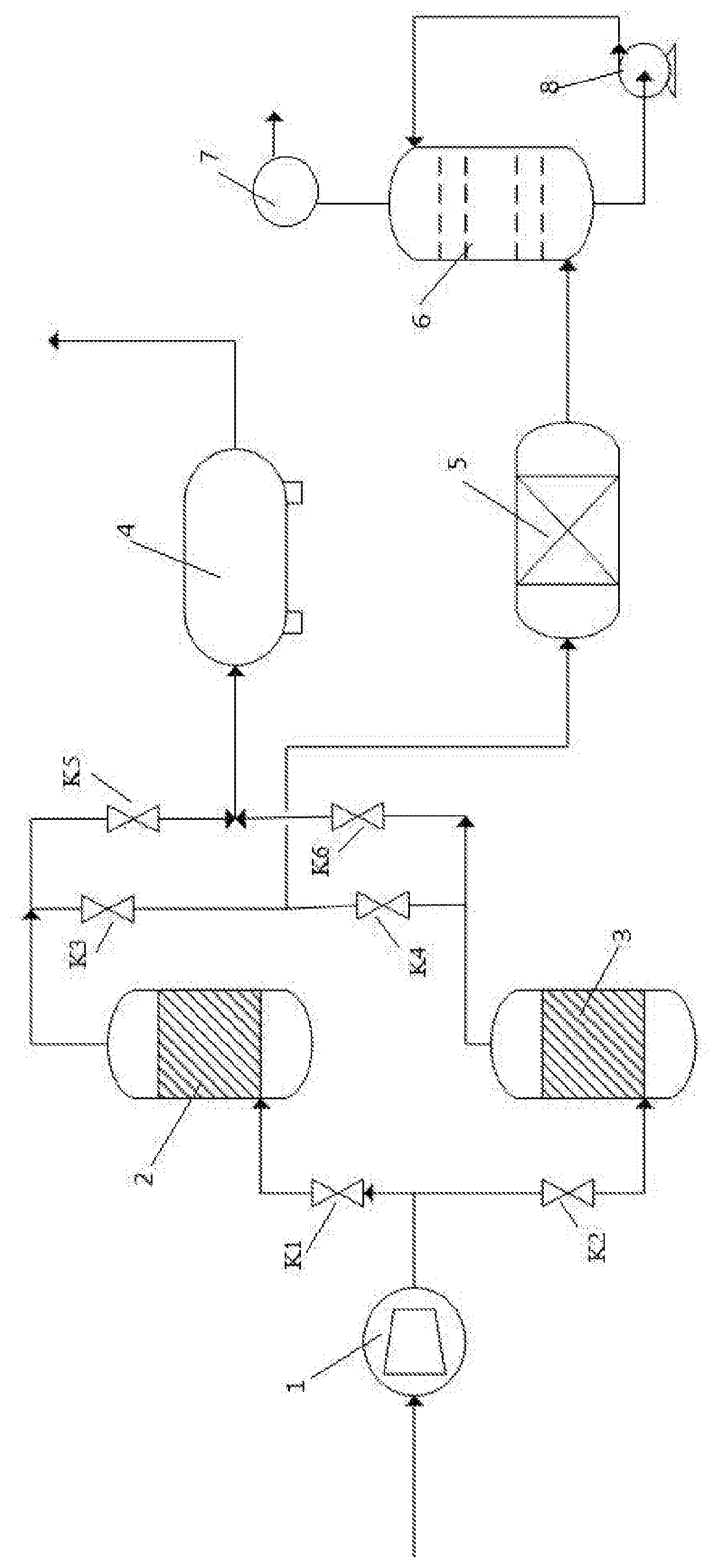

[0033]In the first embodiment, the collected malodorous gas is compressed to 1.0 MPa (A) by the air compressor, and the second valve K2, the third valve K3 and the sixth valve K6 are closed, and the first valve K1 and the fourth valve K4 and the fifth valve K5 are opened. The malodorous gas to be treated compressed by the air compressor 1 enters the first pressure swing adsorption tower filled with granular activated carbon to be deodorized. And the deodorized gas after being fully adsorbed enters the buffer tank. According to actual production needs, the deodorized gas is discharged to the sludge separation tank and the aerobic aeration tank.

[0034]Specifically, in the present embodiment, when the second pressure swing adsorption tower is switched from the adsorption tower to the desorber, the internal pressure of the second pressure swing adsorption tower reaches 1 atm (A), desorption starts.

[0035]The vacuum device 7 is turned on, which adjusts the internal pressure of the second p...

second embodiment

[0036]In the second embodiment, the collected malodorous gas is compressed to 1.2 MPa (A) by the air compressor 1, and the first valve K1, the fourth valve K4 and the fifth valve K5 are closed, and the second valve K2 and the third valve K3 and the sixth valve K6 are opened. The gas compressed by the air compressor 1 enters the second pressure swing adsorption tower 3 filled with granular activated carbon, and the deodorized gas after being fully adsorbed enters the buffer tank 4. Then the deodorized gas is discharged into the sludge separation tank and the aerobic aeration tank according to actual production needs.

[0037]At the same time, the first pressure swing adsorption tower 2 is in a desorption state. Desorption starts when the internal pressure of the first pressure swing adsorption tower 2 reaches 1 atm (A). The vacuum device is turned on to start to maintain the pressure in the first pressure swing adsorption tower 2 at 0.05 MPa (A). After 3 hours of sufficient desorption, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal pressure | aaaaa | aaaaa |

| internal pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com