Premixing apparatus

a technology of pre-mixing apparatus and pre-mixing liquid, which is applied in the direction of burners, fuel supply regulation, combustion types, etc., can solve problems such as failure of combustion, and achieve the effects of reducing the rotational speed of the fan, ensuring wind resistance performance, and reducing the minimum amount of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

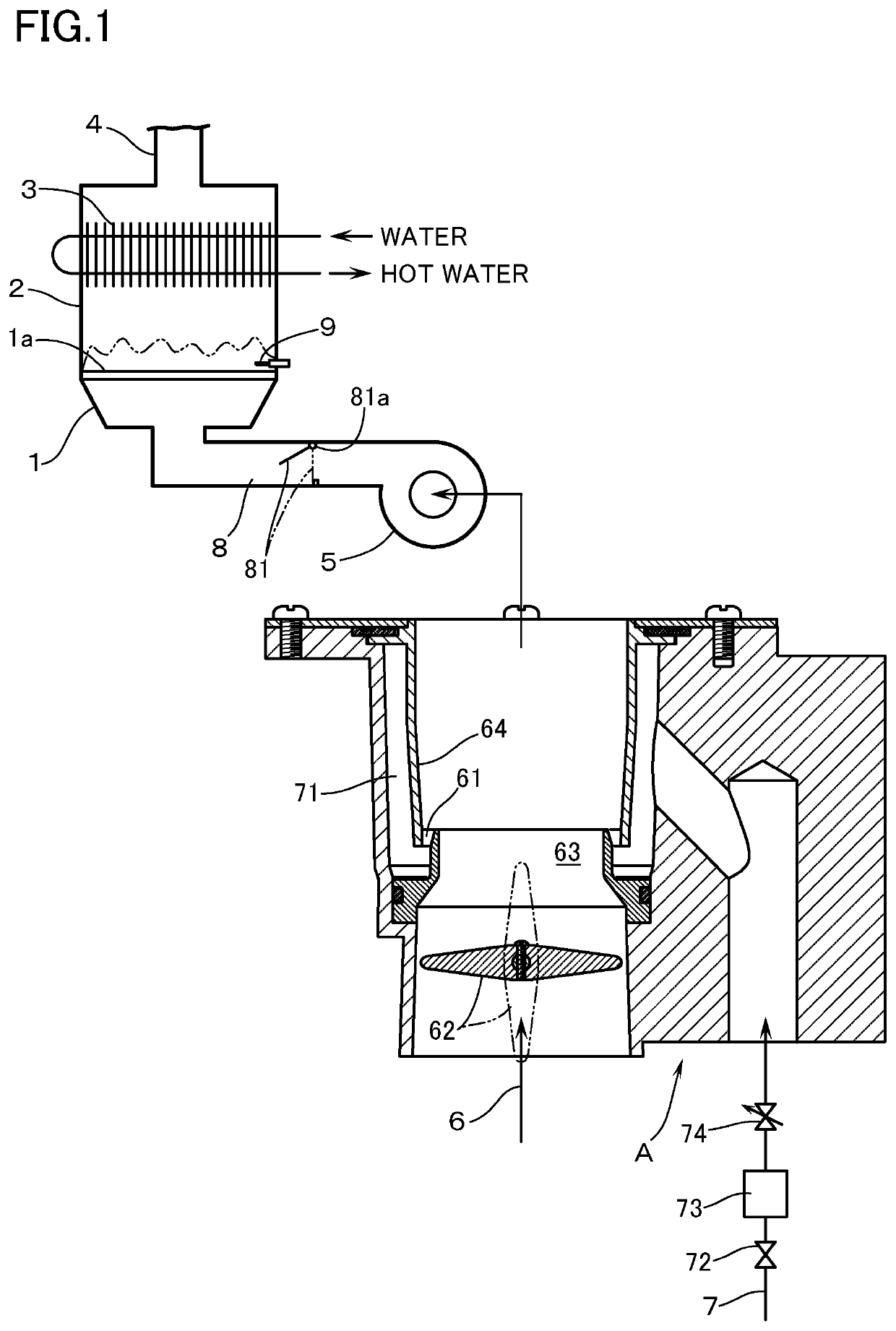

first embodiment

[0025]Even in case the kind of gas of the fuel gas is changed, the excess air ratio of the air-fuel mixture can be made to the appropriate value by the control of the flow control valve 74. It is to be noted however that, in order to cope with the change to a gas with a largely different calorific value, it becomes necessary to largely change the flow resistance in a portion, on a downstream side of the zero governor 73, of the gas supply passage 7. In the arrangement of the first embodiment, it becomes necessary to make relatively wider the range of opening degree change of the flow control valve 74. For that purpose, the amount of change in opening degree per unit operation amount of the flow control valve 74 will be obliged to be made larger. As a consequence, the allowable error in the operation amount becomes slight, thereby deteriorating the controllability of the flow control valve 74.

second embodiment

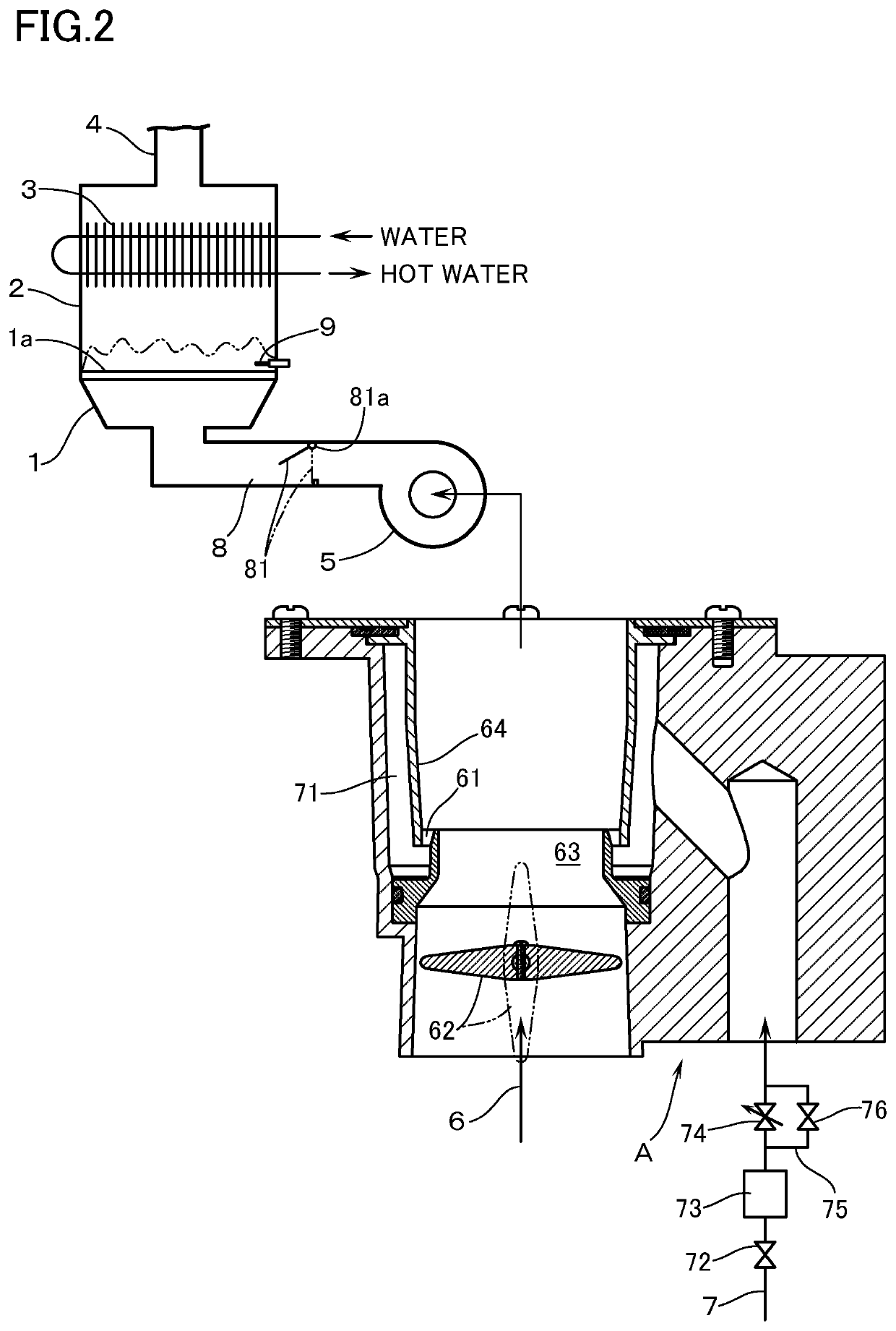

[0026]On the other hand, even if the change width of opening degree of the flow control valve 74 is not so large, the flow resistance in a portion, on the downstream side of the zero governor 73, of the gas supply passage 7 can be varied over a wide range: by the opening degree change in the state in which the fuel gas does not flow through the bypass passage 75 as a result of closing the on-off valve 76; and by the opening degree change of the flow control valve 74 in a state in which the fuel gas flows through the bypass passage 75 as a result of opening the on-off valve 76. Therefore, the deterioration in the controllability of the flow control valve 74 due to enlargement of the range in opening degree change can be avoided.

[0027]Descriptions have so far been made of the embodiments of this invention with reference to the figures, but this invention shall not be limited to the above. For example, in the above-mentioned embodiments, in order to switch the capacity, the flow resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com