Nylon Artificial Grass

a technology of synthetic grass and nylon, applied in the direction of applications, roads, constructions, etc., can solve the problems of retaining deformation, no manufacturer is known by the applicant to provide multi-color nylon face fabric, and no manufacturer is known by the applicant to utilize nylon face fiber in combination with nylon, so as to increase durability and/or resilience, increase aesthetic appeal, and increase durability. the effect of resiliency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

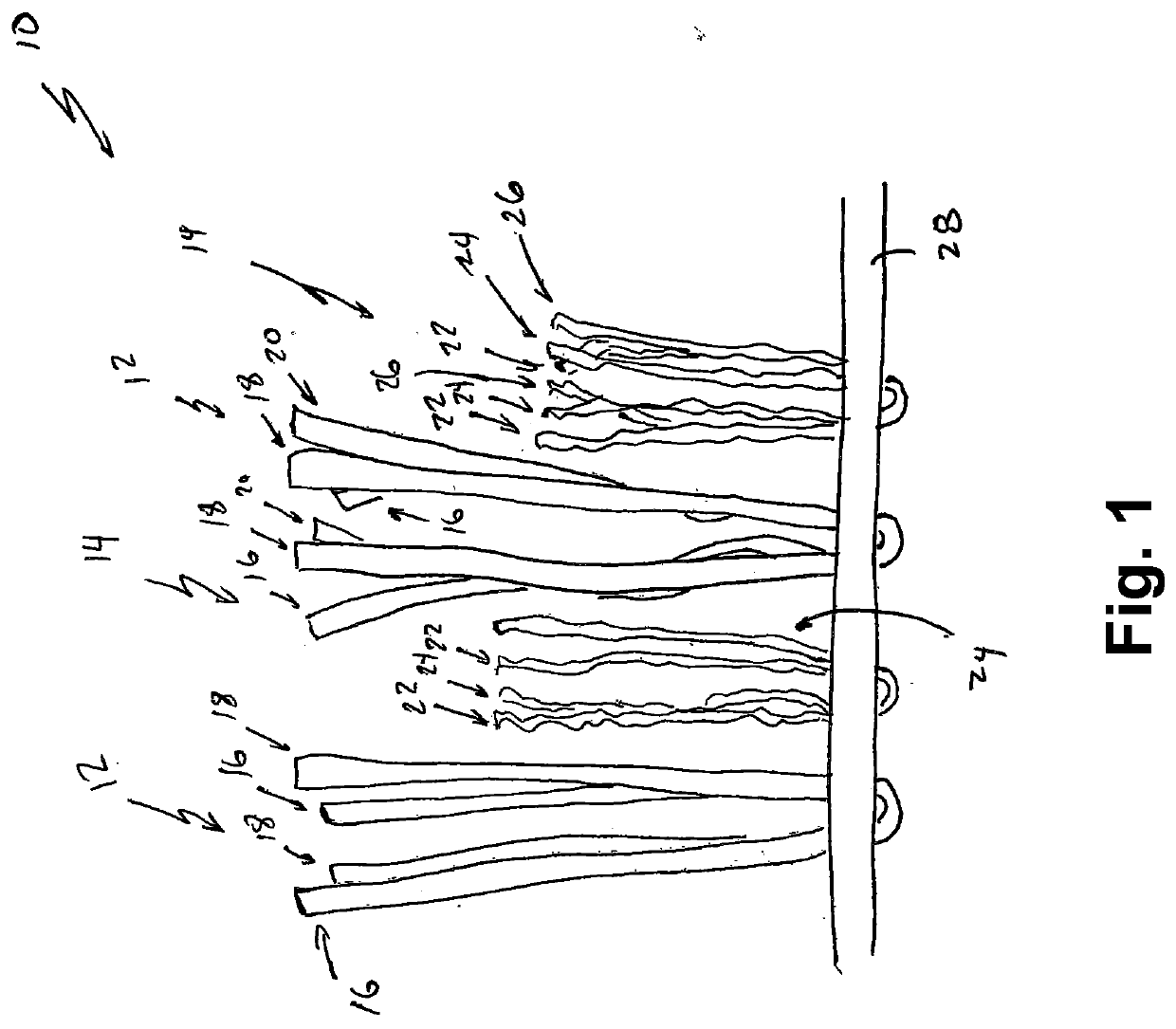

[0018]The FIGURE shows a presently preferred embodiment of the present invention in the form of artificial grass product 10 having face fiber tufts 12 and thatch fiber tufts 14. The tufts 12 of face fiber are preferably comprised of at least two different filaments or strands 16, 18 of yarn, both of which are preferably nylon and which may also be different colors. The FIGURE also shows an adjacent tuft with those same two filaments or strands 16, 18 as well as third filament or strand 20 which could be one of those two colors or a third color. Tufts 12,14 are directed through backing 28 as would be understood by those of ordinary skill in the art. Backing 28 may be nylon or other material. As referenced herein, 100% nylon refers to the tufts 12,14 and not the backing 28 or possibly other materials added below the backing 28.

[0019]Additional strands could be provided in tuft of strands 16,18,20 or others as well. One embodiment that the applicant is about to launch will have a tan, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com