Steel gondola railcar

a technology for gondolas and railcars, applied in the field of railcars, can solve the problems of railcar damage or failure, steel tends to dent severely in service, and it is difficult to form welds that can withstand forces and tensions, and achieves the effects of low weight of gondola cars, high strength, and high abrasion resistance steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

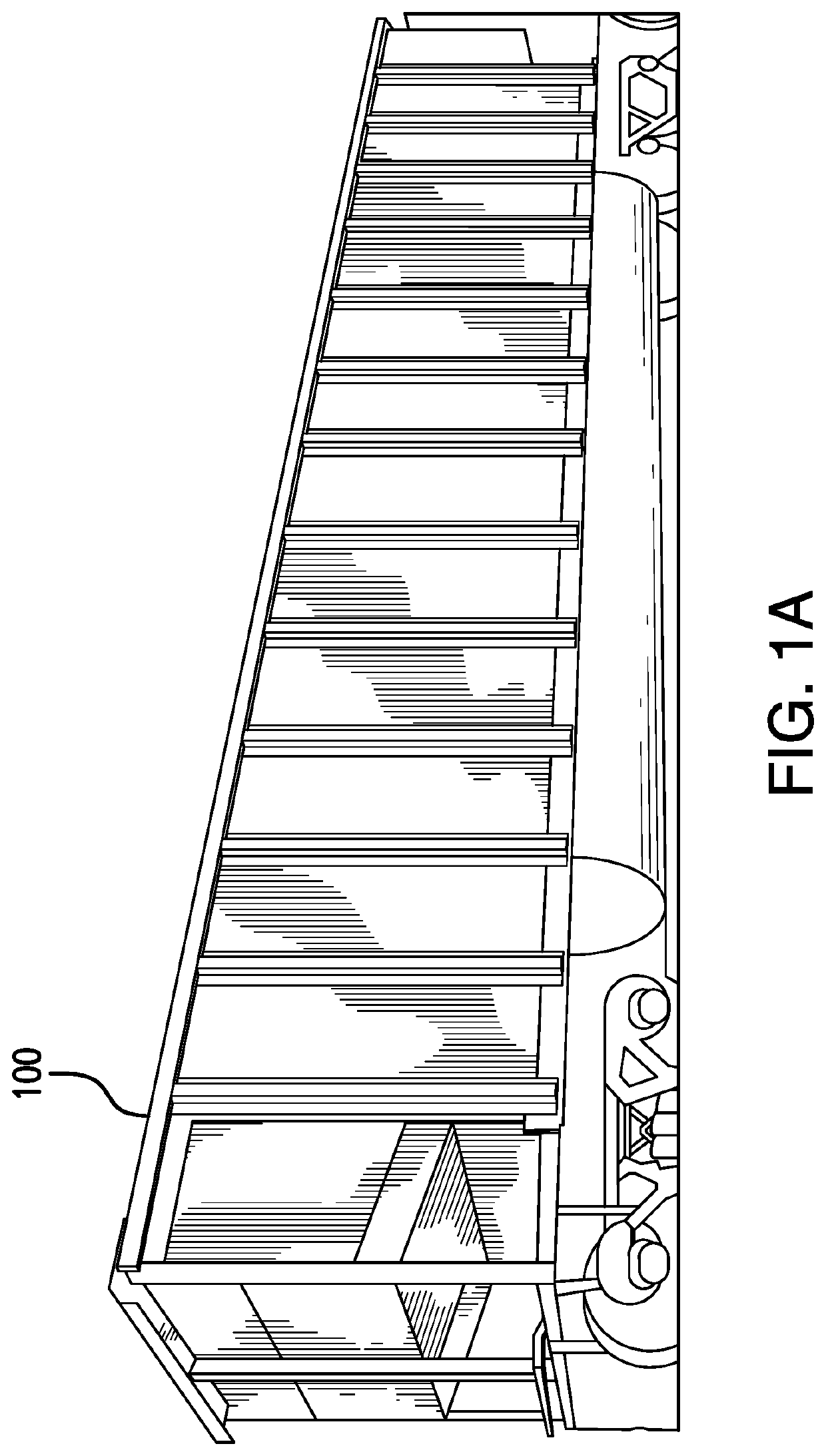

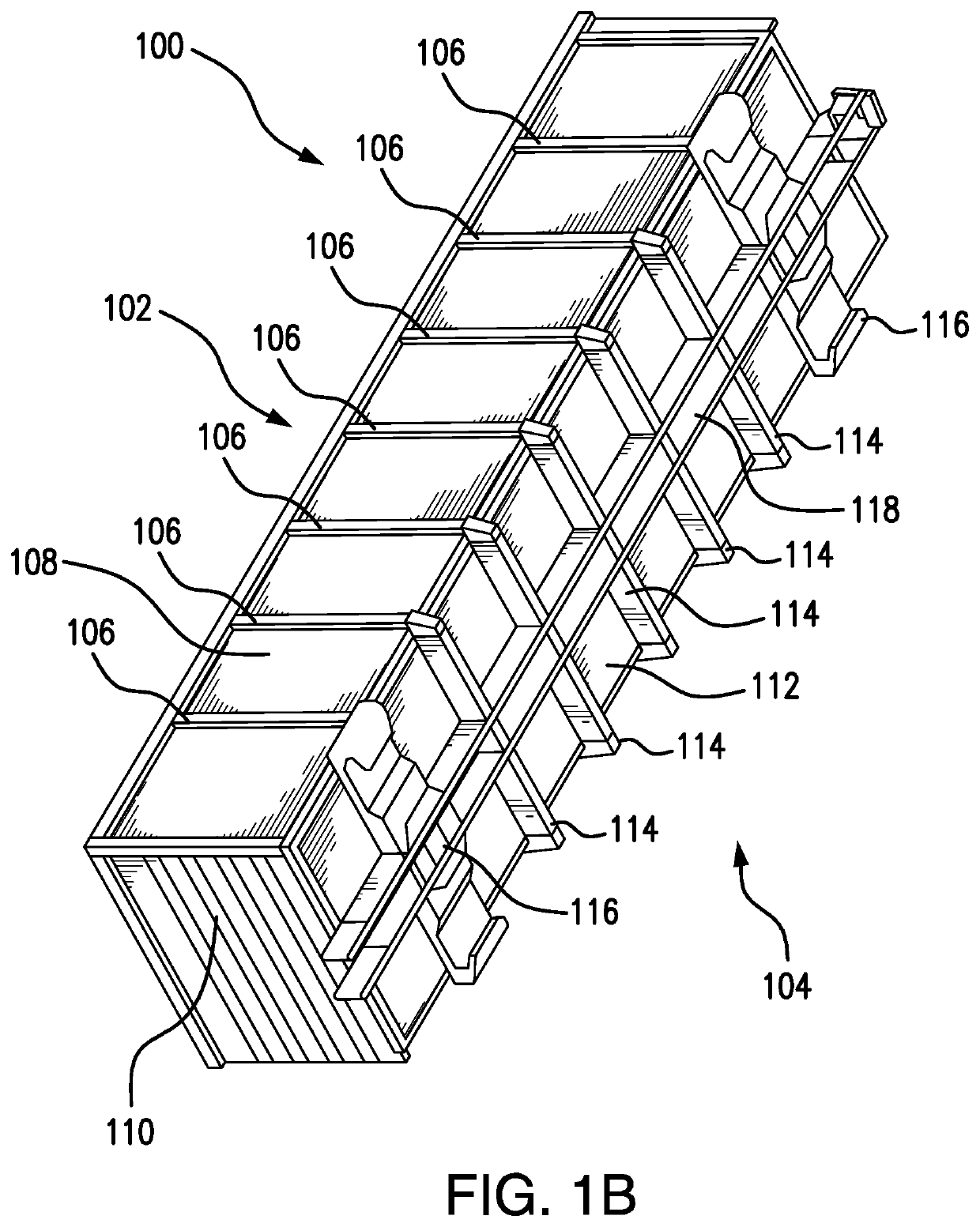

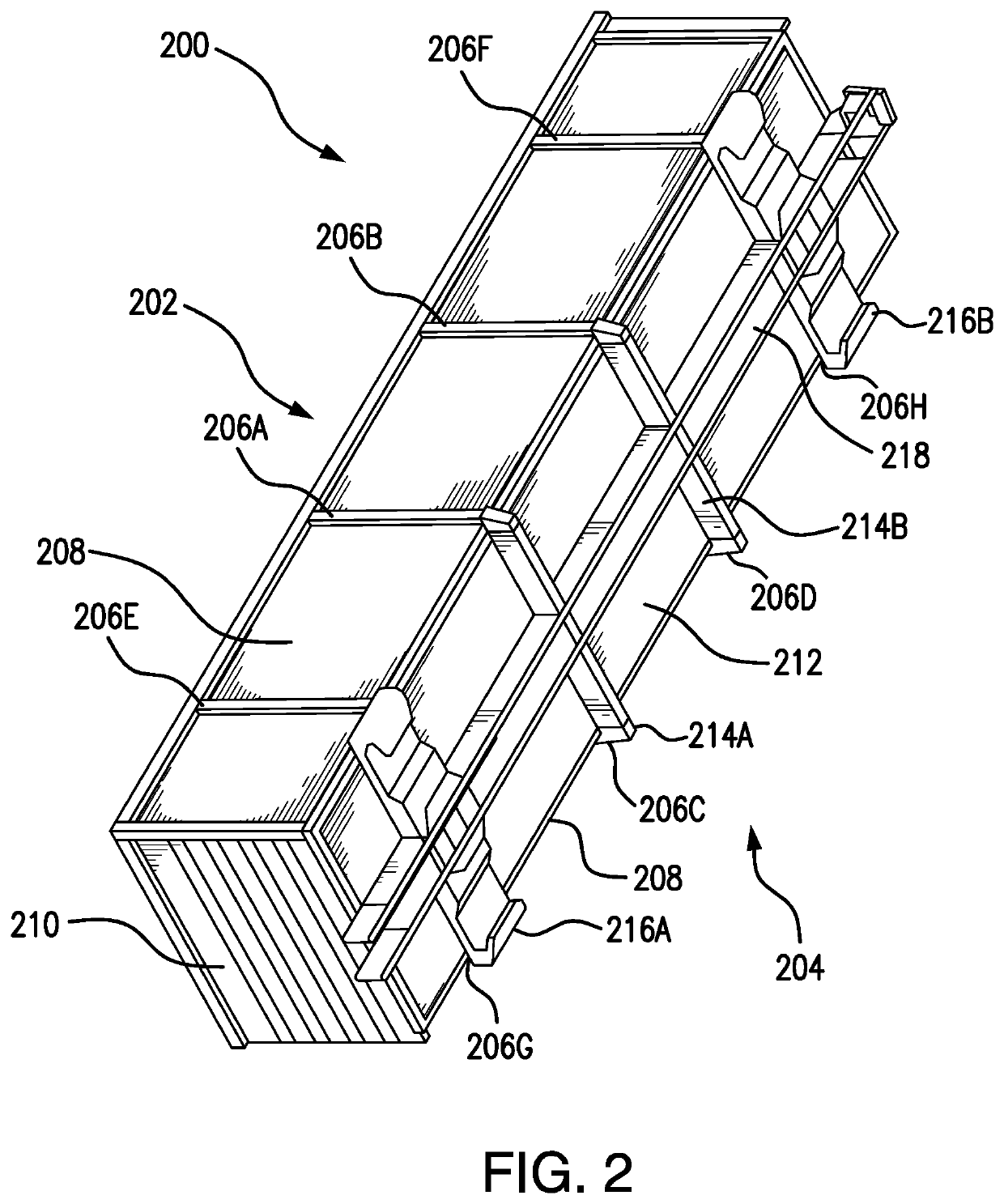

[0016]Certain embodiments of the present disclosure and inventive concepts, and their features and advantages, may be understood by referring to FIGS. 1A, 1B, and 2, like numerals being used for corresponding parts in the various drawings.

[0017]This disclosure contemplates using a high strength and high abrasion resistance steel in manufacturing a gondola car. The gondola car may benefit from the high strength and high abrasion resistance steel through a significant reduction on the total weight of the gondola car and fewer welded areas in the bottom and sides of the gondola car to enhance its durability. To address weldability concerns presented by the steel, components (e.g., side posts and cross-bearers) are positioned at locations on the gondola car that experience the least amount of stress when transporting goods, rather than positioning several side posts and cross-bearers across the gondola car. This positioning may result in fewer components being welded to the gondola car....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com