Method and apparatus for increasing the efficiency of the cogeneration power plant by the heat pump principle utilization for increasing the coolant inlet temperature

a technology of heat pump and heat pump blade, which is applied in the direction of lighting and heating apparatus, sustainable buildings, heating types, etc., can solve the problems of poor cop of heat pump, and low heat transfer efficiency of heat pump, so as to improve cop, improve heat transfer efficiency, and reduce fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

ples

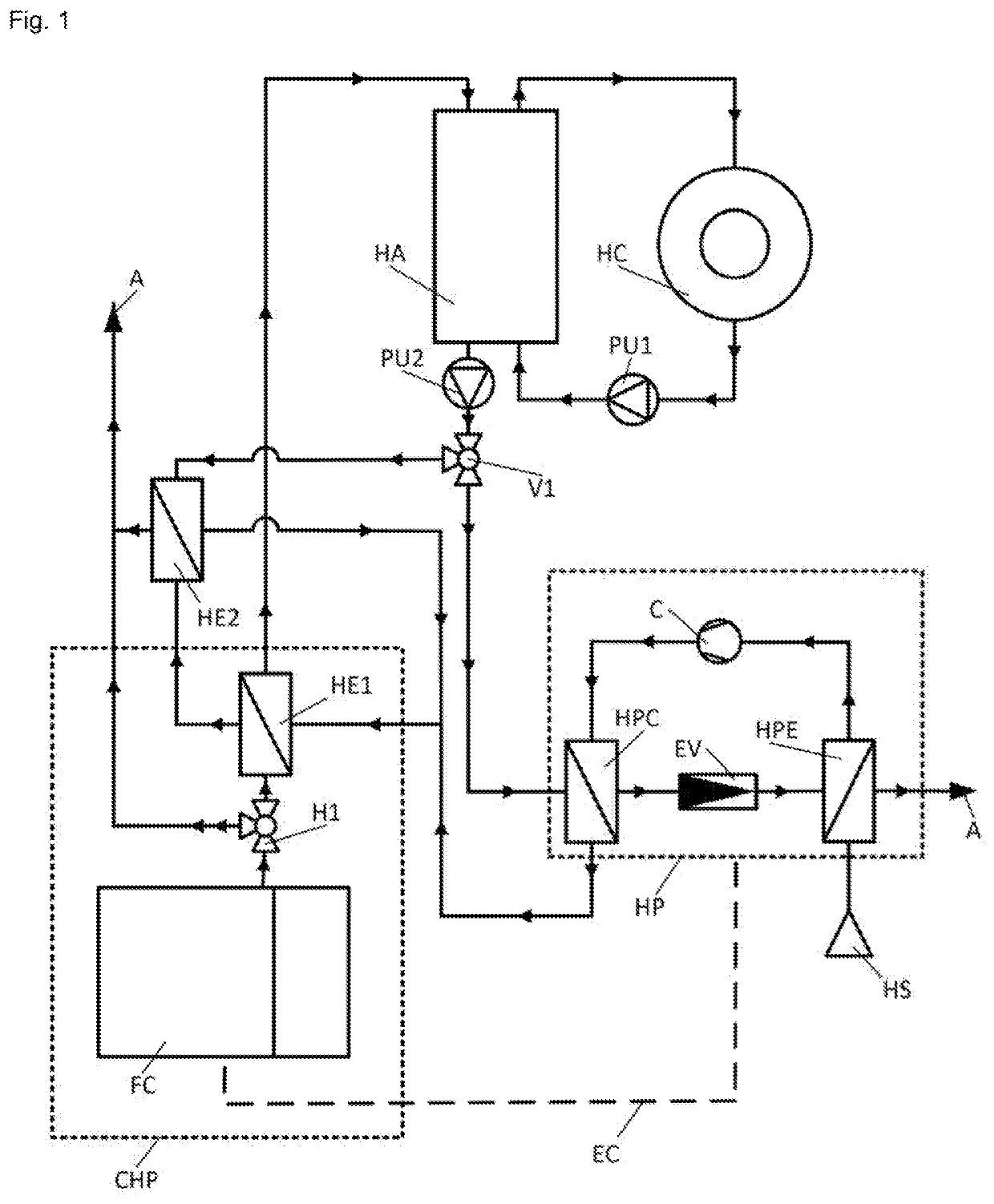

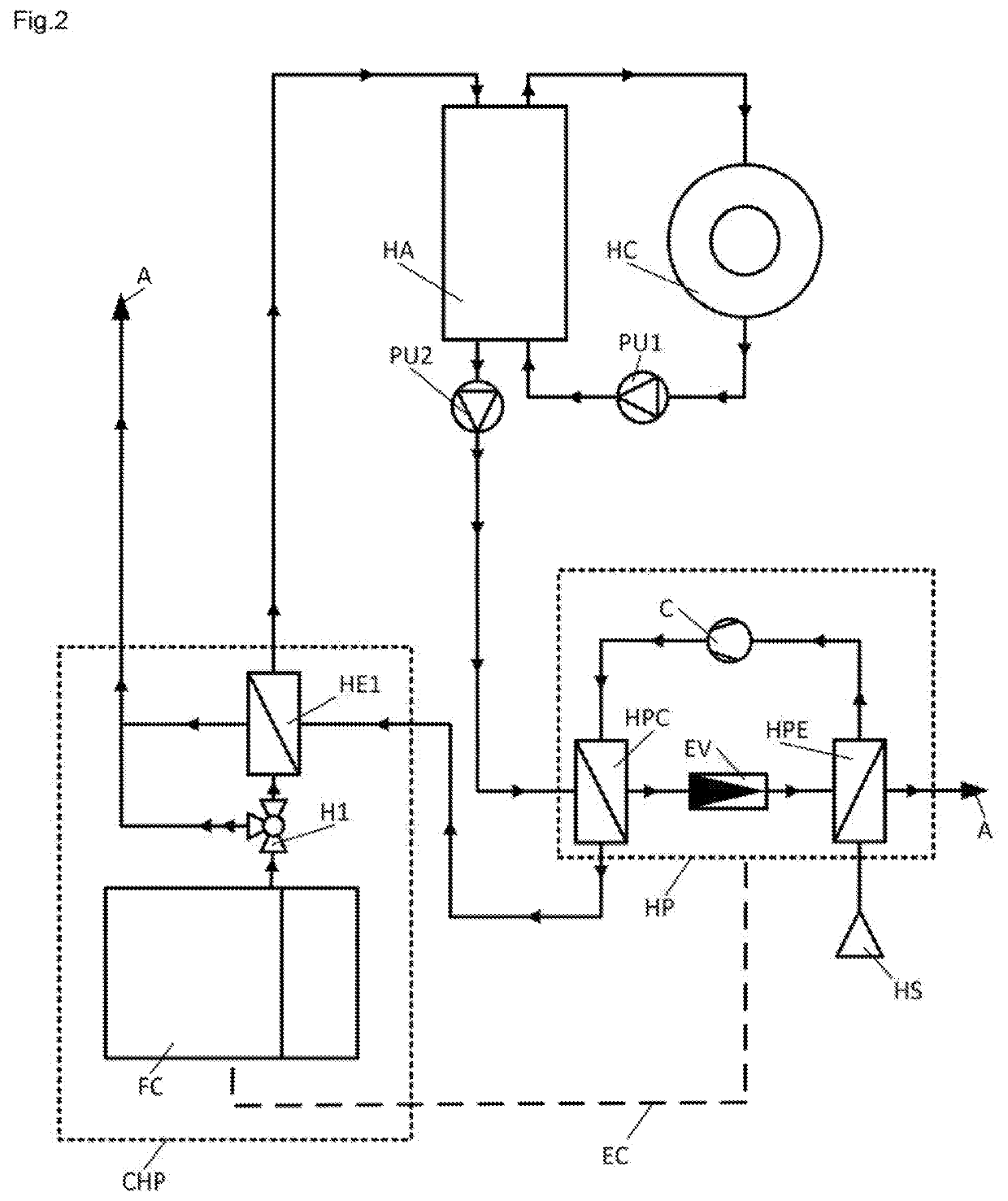

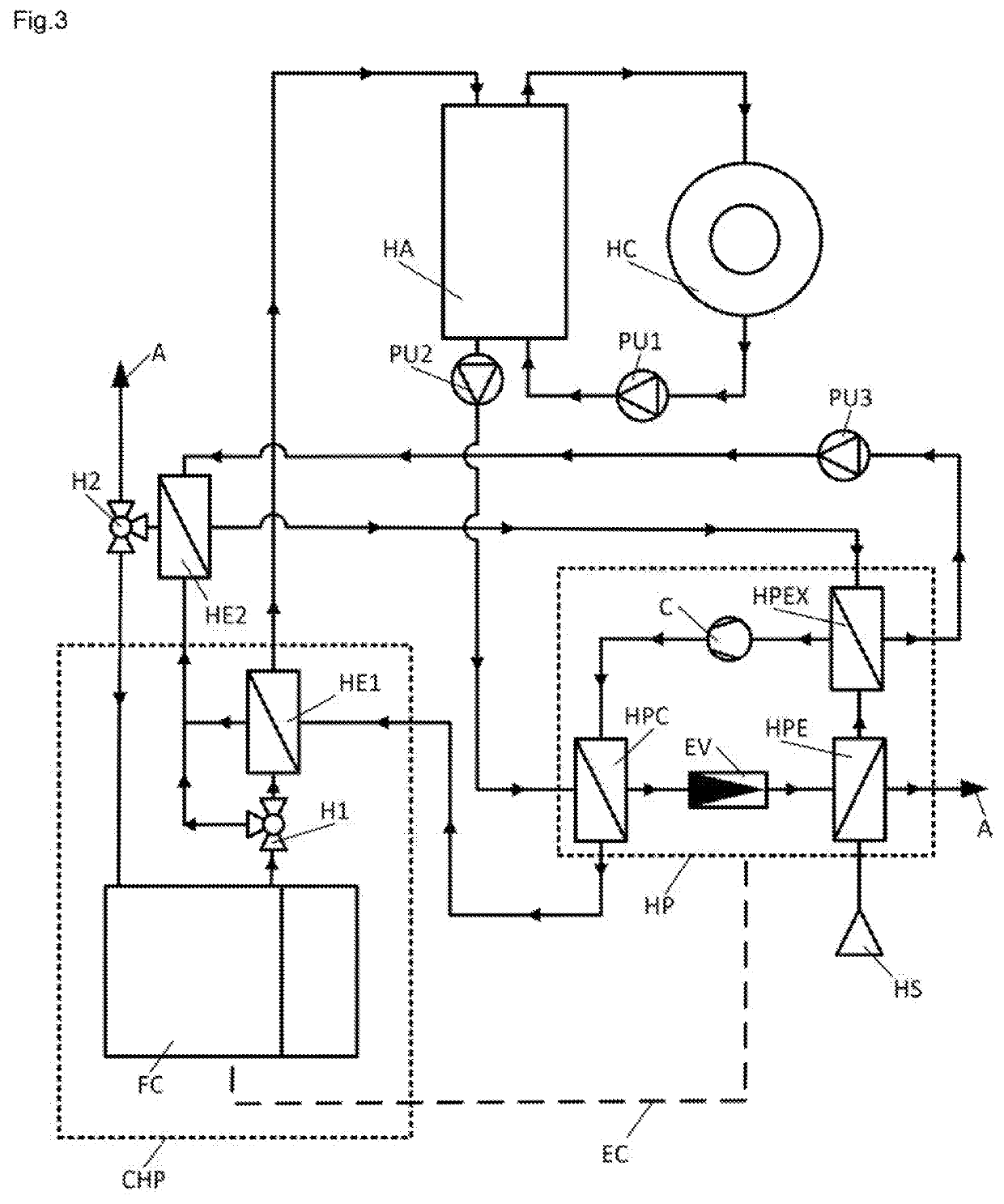

[0021]In preferential embodiment, the cogeneration of heat and power (CHP) assembly comprises at least one primary heat source (i.e. fuel cell (FC) or internal combustion engine (ICE)) with adapted heat exchangers (HE1, HE2) for waste heat (i.e. flue gas) recuperation, and at least one heat pump (HP) with adapted evaporator (HPE) for renewable energy source (HS) utilization. As can be read out from the FIG. 1 and FIG. 4, the waste heat of said primary heat source for the cogeneration of the heat and power (CHP) assembly is at least partially introduced into the heat distribution network by heat exchangers (HE1, HE2), wherein the high-temperature heat of the flue gas is introduced into the supply line of the heat distribution network by the first heat exchanger (HE1) (i.e. the temperature of the flue gas is reduced below 140° C.), and similarly, the second heat exchanger (HE2) is preferably adapted to utilize the residual, low-temperature heat, by reducing the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com