Athletic Glove Strengthened by Applying a Coating Layer

a technology of coating layer and glove, applied in the field of athletic gloves, can solve the problems of degrading the quality of athletic gloves, high manufacturing cost, and high labor intensity of splicing and seaming steps, so as to prevent finger knuckle injury, improve structural strength, and effectively offset impact force and rotational for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

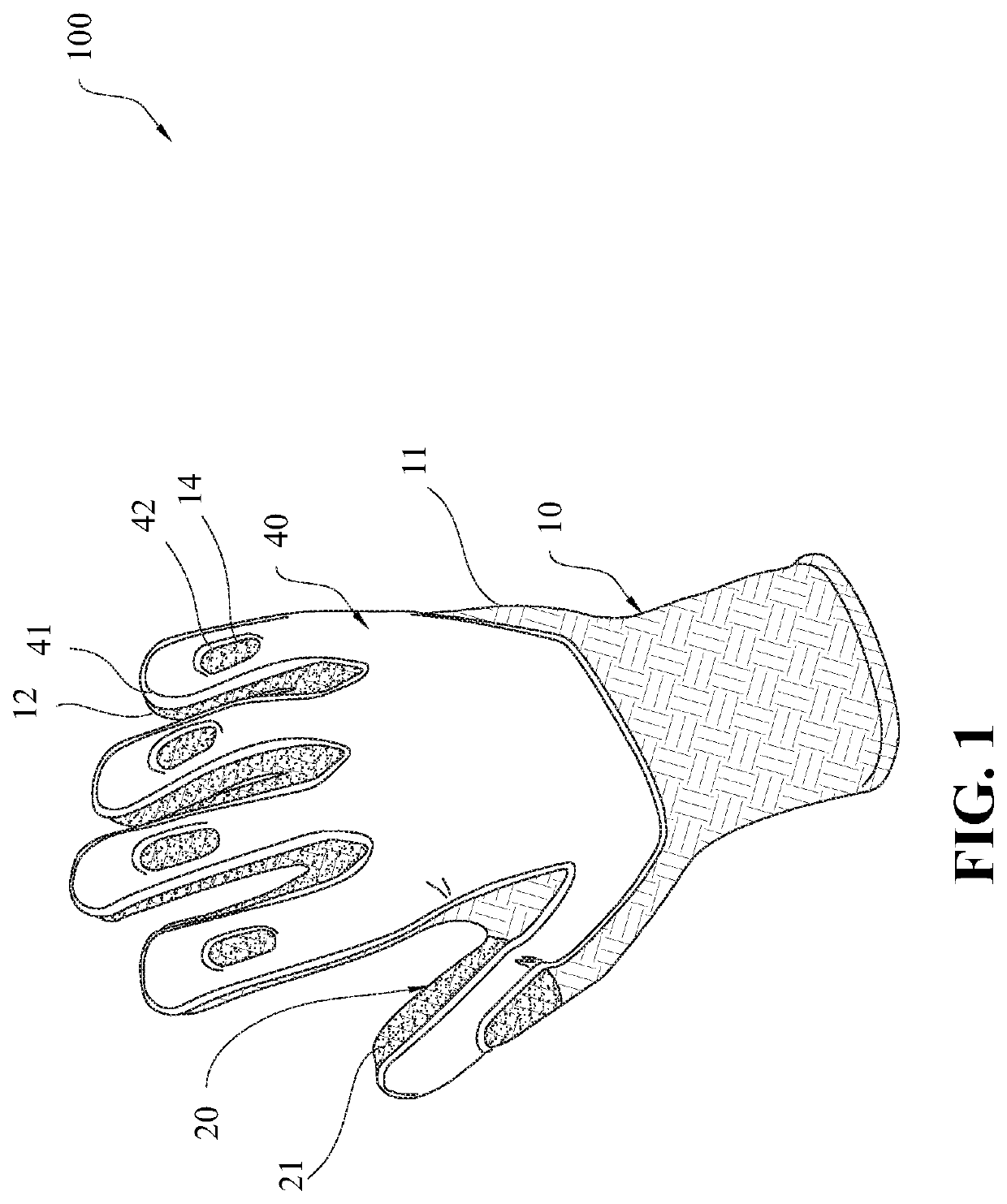

[0028]Referring to FIGS. 1 to 5, FIG. 1 and FIG. 2 are the perspective views of the first embodiment of the present invention, and FIG. 3, FIG. 4 and FIG. 5 are the exploded perspective view, the partial cross-sectional view and the partial enlarged view of the first embodiment of the present invention, respectively. The athletic glove 100 according to the present invention includes a glove body 10, a coating layer 20, a first protective layer 30 and a second protective layer 40.

[0029]The glove body 10 is formed with a palm portion 11 and a plurality of finger sleeve portions 12, wherein a front side of the glove body 10 is a surface for an anterior part of a hand and a back side of the glove body 10 is a surface for an posterior part of the hand, and the glove body 10 is interwoven by a plurality of yarns 13. According to this embodiment, the yarns 13 of the glove body 10 are elastic fibers such that the glove body 10 is stretchable.

[0030]The coating layer 20 is applied on each of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

| elastic deformation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com