Scraper sponge

a sponge and sponge technology, applied in the field of sponges, can solve the problems of inconvenient use of the device, inability to effectively remove substances from the abrasive layer, and too soft and pliable sponges to scrape away unwanted substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention is directed to a scraper sponge and / or pad adapted for scraping and removing unwanted substances such as dirt, hardened oils or grease, mildew, waxes, stuck on foods, or other substances that adhere to surfaces and reside in corners, grooves and crevices.

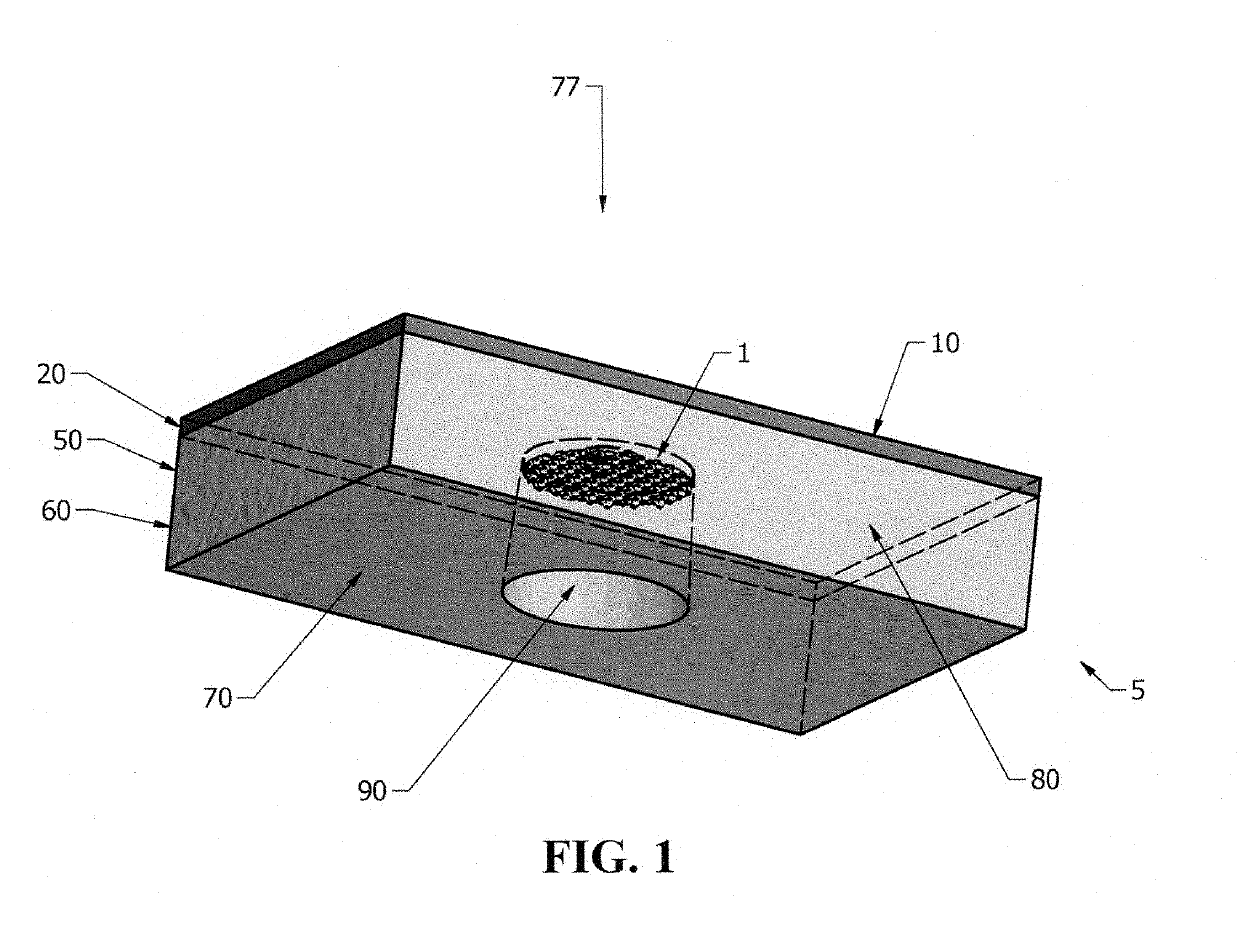

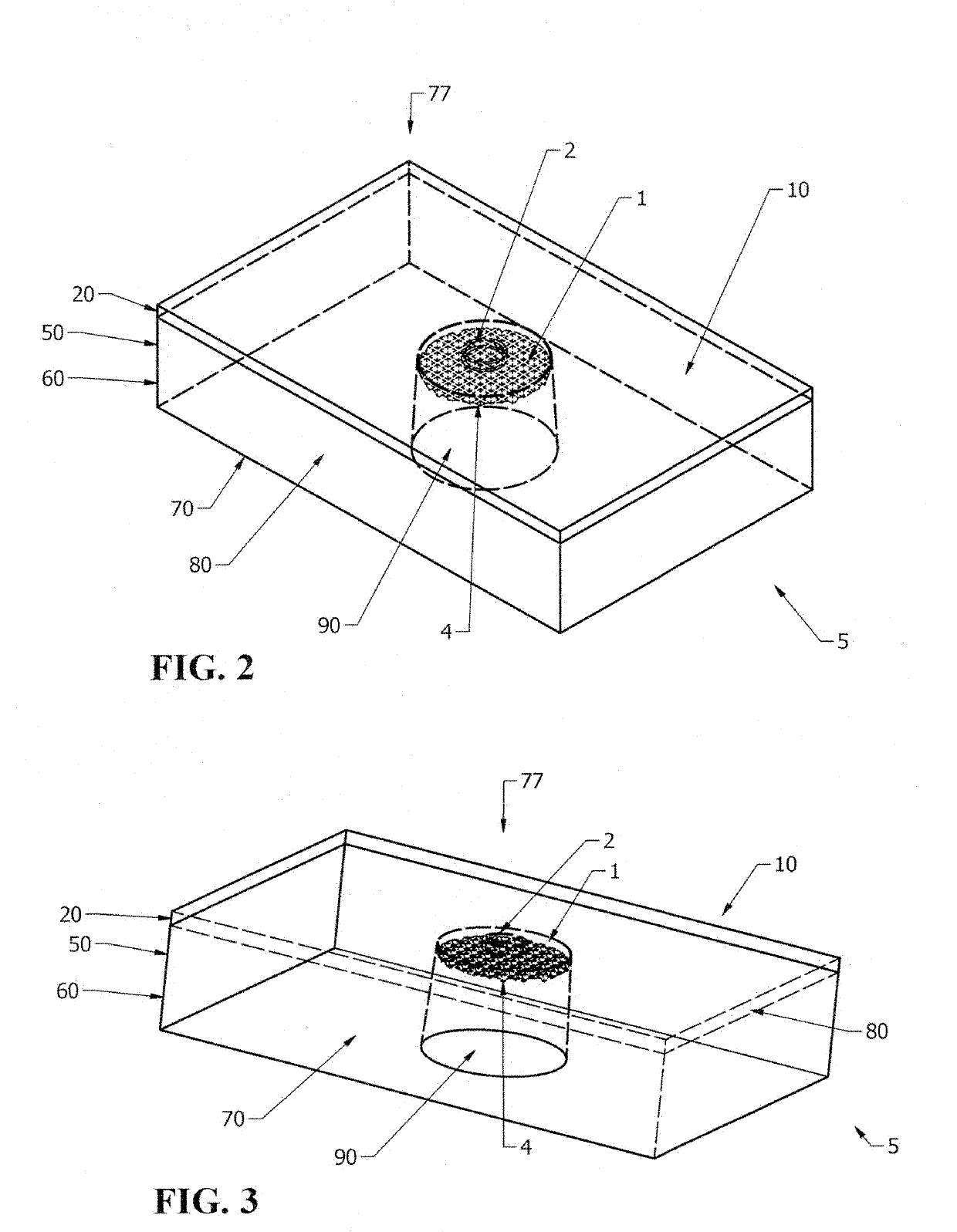

[0030]Referring to FIGS. (1 Thru 4) an embodiment of the scraper sponge is shown and generally indicated by reference numeral 5. The scraper sponge 77 comprises a sponge body 5 defining a first surface 10, second surface 70 opposite first surface, and a continuous side surface 80 around the perimeter. The sponge body 5 can be made from numerous materials such as polyester foam, natural sponges, polyurethane foams, cellulose fiber, absorbent arrays of synthetic fibers or any combination thereof. The invention is not limited in this regard, and any appropriate sponge material that is currently known or later becomes known to those skilled in the art may be used. In one embodiment, the sponge body 5 is recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com