Dirt removal and piling machine

a technology of piling machine and dirt, which is applied in the field of machines, can solve the problems of reducing the sugar content of beets, causing spillage, and causing rot and a reduction of sugar content, so as to minimize such spillage, facilitate disassembly and placement of modules, and reduce damage and bruises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

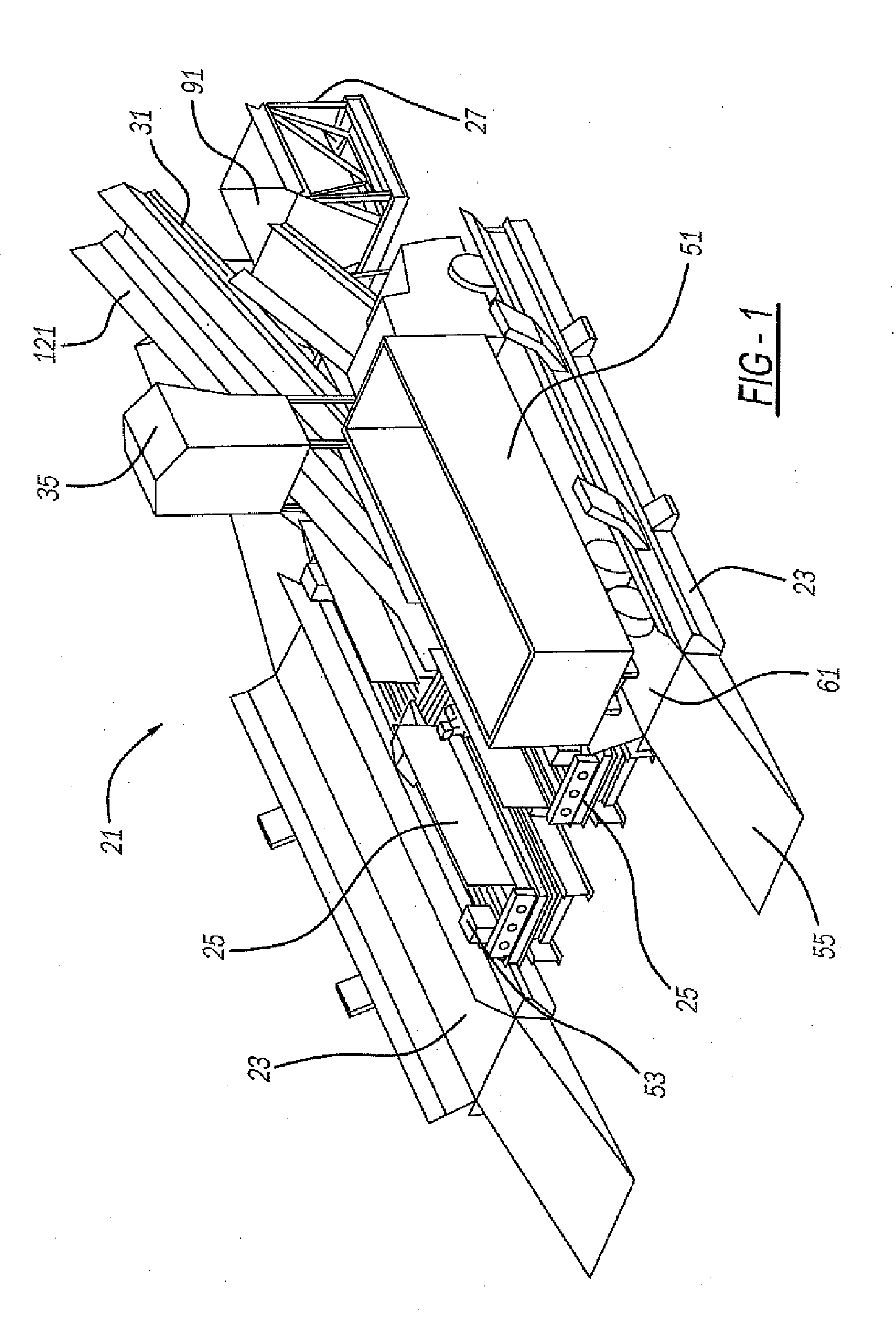

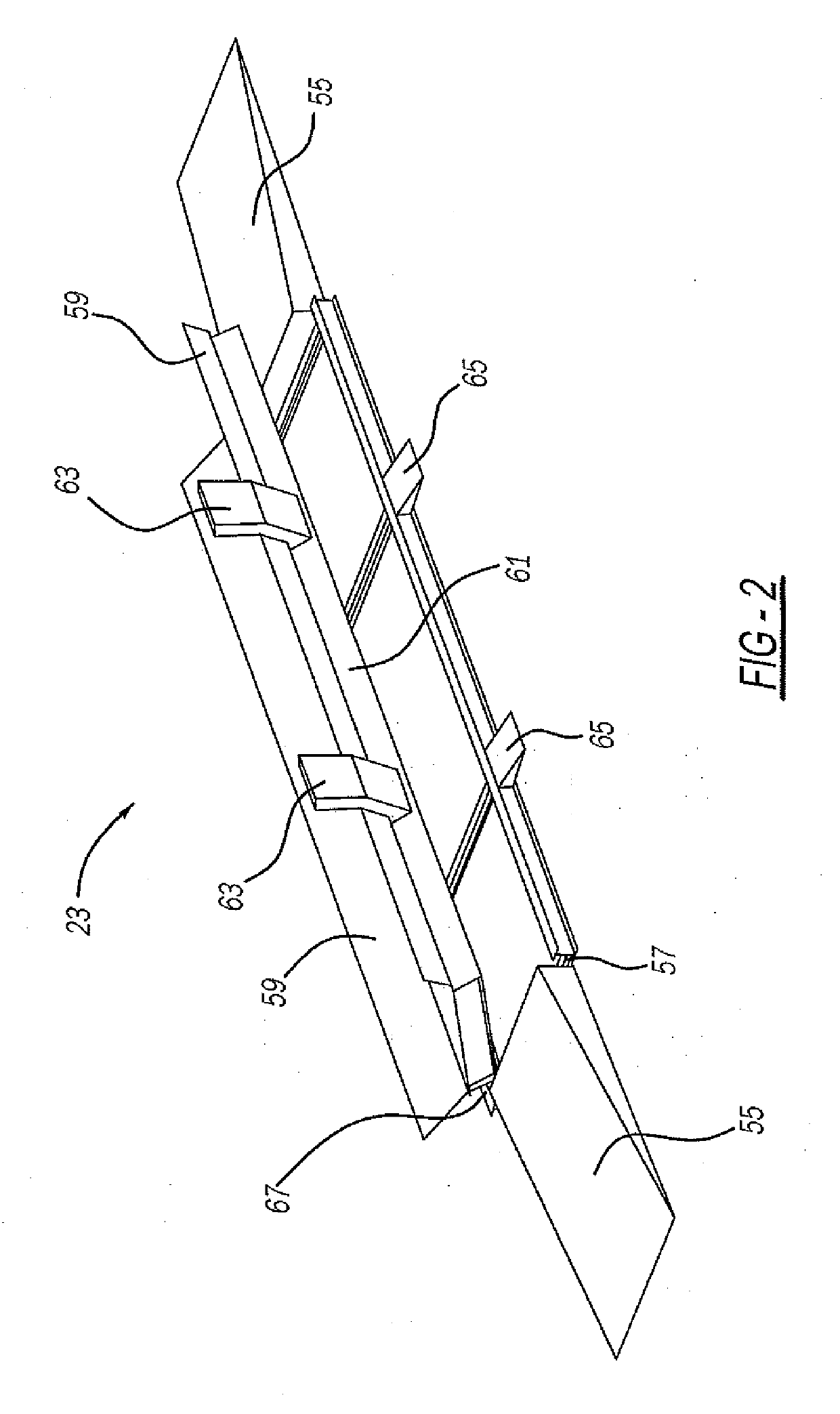

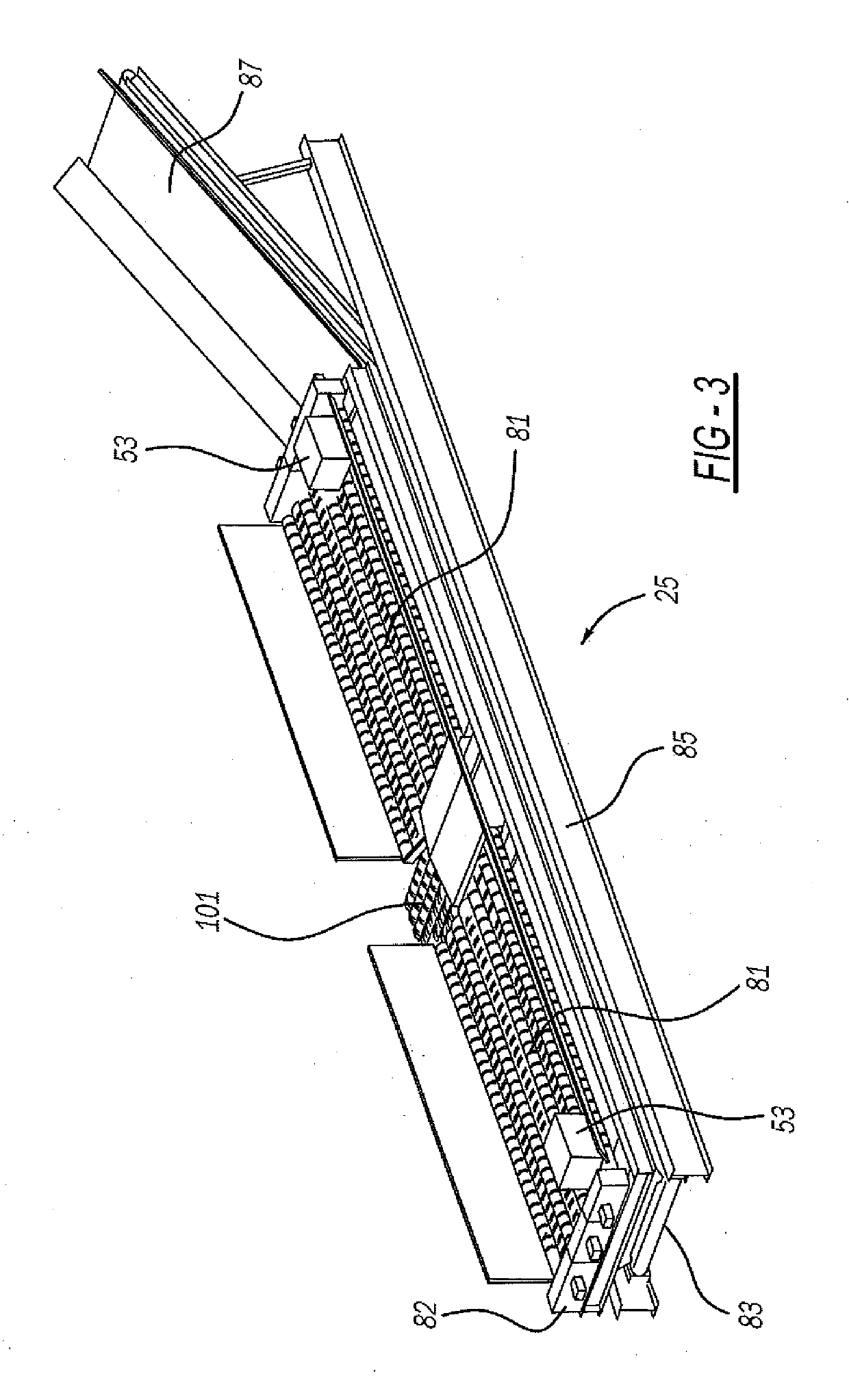

[0032]Referring to FIGS. 1-7, a dirt removal and workpiece piling machine 21 includes a pair of sugar beet receiving and offloading stations 23, a pair of cleaning stations 25, a dirt dumping station 27, a sampling station 29, a central and main conveyor station 31, a piling conveyor 33 and a control room 35. A class 8 semi-truck or other such dump truck 51 includes an open-topped trailer which contains individualized and nonuniformly shaped workpieces, such as sugar beets 53. Truck 51 is longitudinally driven onto a bed of unloading station 23. When bed 61 is in its nominal horizontal position and a rearward ramp 55 is raised, the truck upwardly pivots its trailer about a lateral rear axis to dump out its load of beets through a rear opening gate as the truck longitudinally drives forward and off of the forwardmost ramp 55. Thereafter, both ramps 55 are upwardly rotated about horizontal pivot axes 57 (which may alternately be in the center of the ramp so only ends of the ramp are r...

second embodiment

[0044]a dirt removal and piling machine 301 can be observed in FIGS. 9-11. Machine 301 includes a workpiece-receiving station 303, a feed conveyor table assembly 305, a cleaning station 307, a dirt removal and transporter 309, and a series of main piling conveyors 311. At least one, more preferably at least three, and in the illustrated example, sixteen main piling conveyors 311 are employed in an overlapping fashion with a distal piling conveyor 313 being telescopically extendable and taller than the preceding piling conveyors. Each of the piling conveyors are portable such that they may be removed from the serial chain as distal piling conveyor 313 unloads beets onto a beet pile 315 in an arcuate manner as it is wheeled about its vertical pivot axis adjacent its lower end. When an intermediate conveyor 311 is removed, distal conveyor is moved closer to cleaning station 307 so as to increase the on-ground pile size in a longitudinal direction toward the cleaning station. Each pilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com