Single-stage centrifugal pumping unit

a centrifugal pumping unit, single-stage technology, applied in the direction of pump installation, non-positive displacement fluid engine, liquid fuel engine components, etc., can solve the problems of significant reduction in efficiency and reliability, increase in reliability of operation, loss of energy, etc., to achieve peak efficiency and simplify design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]To ensure comprehensive understanding of the essence of the present invention, its numerous specific characteristics will be described hereinafter.

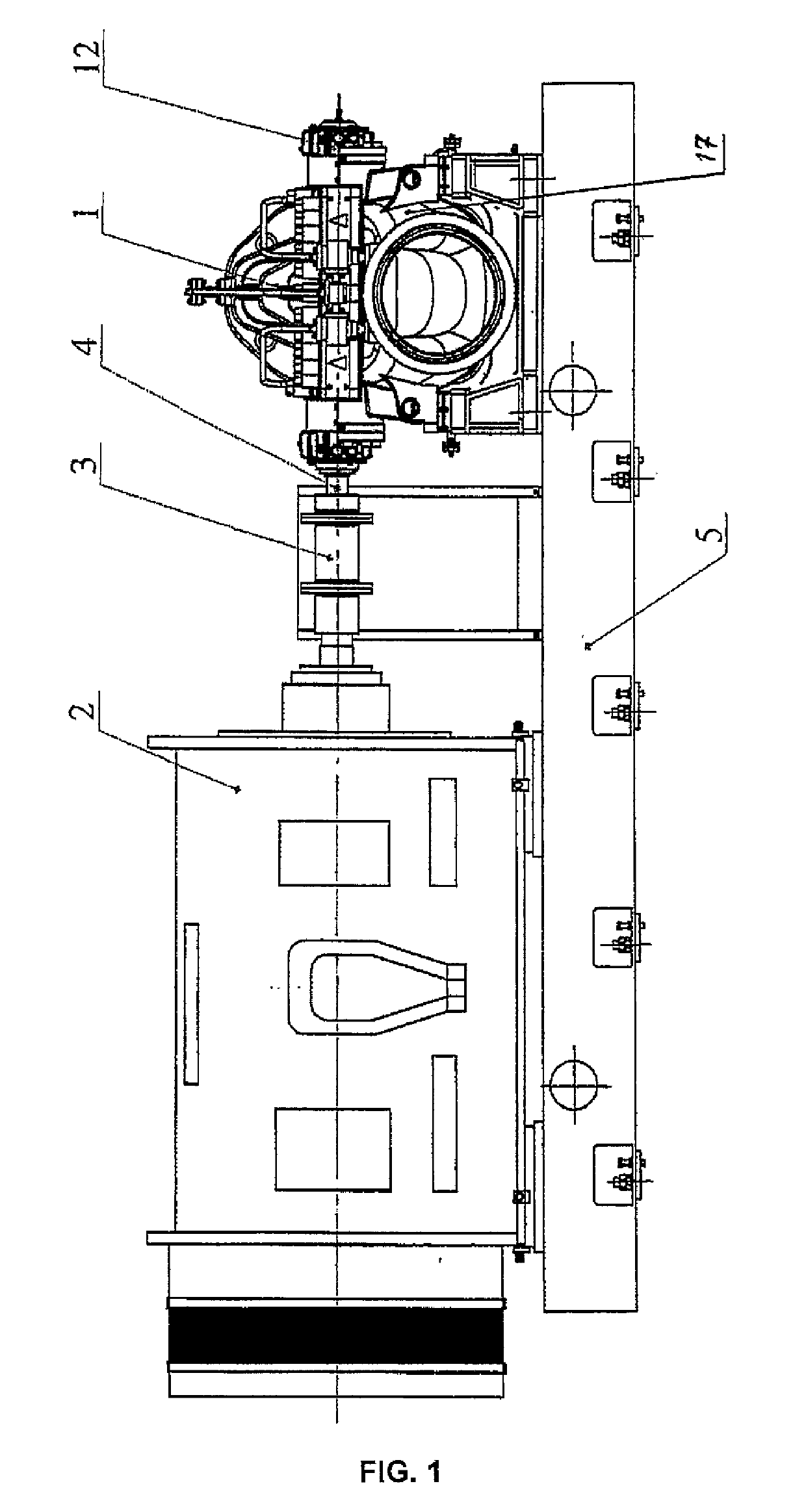

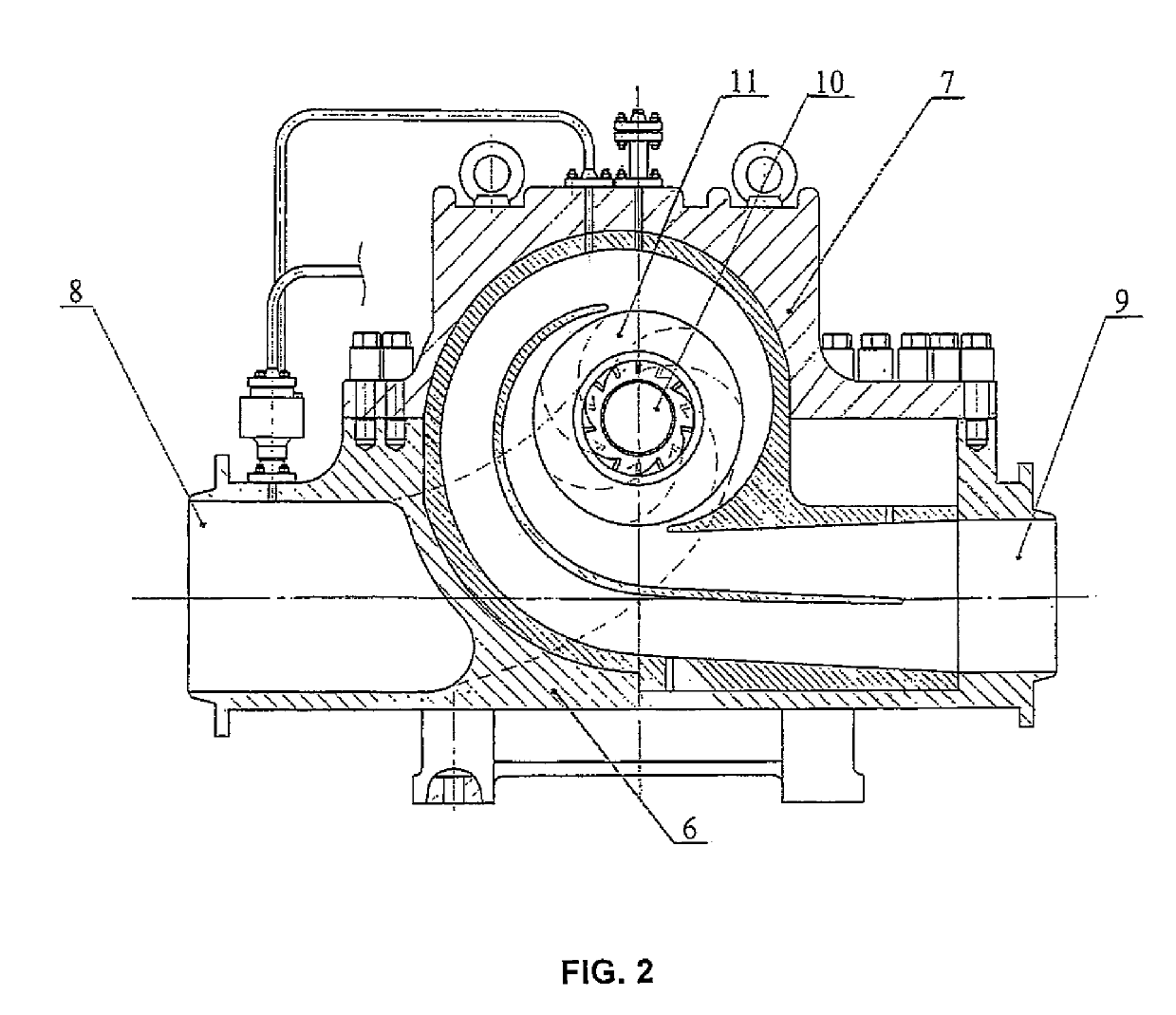

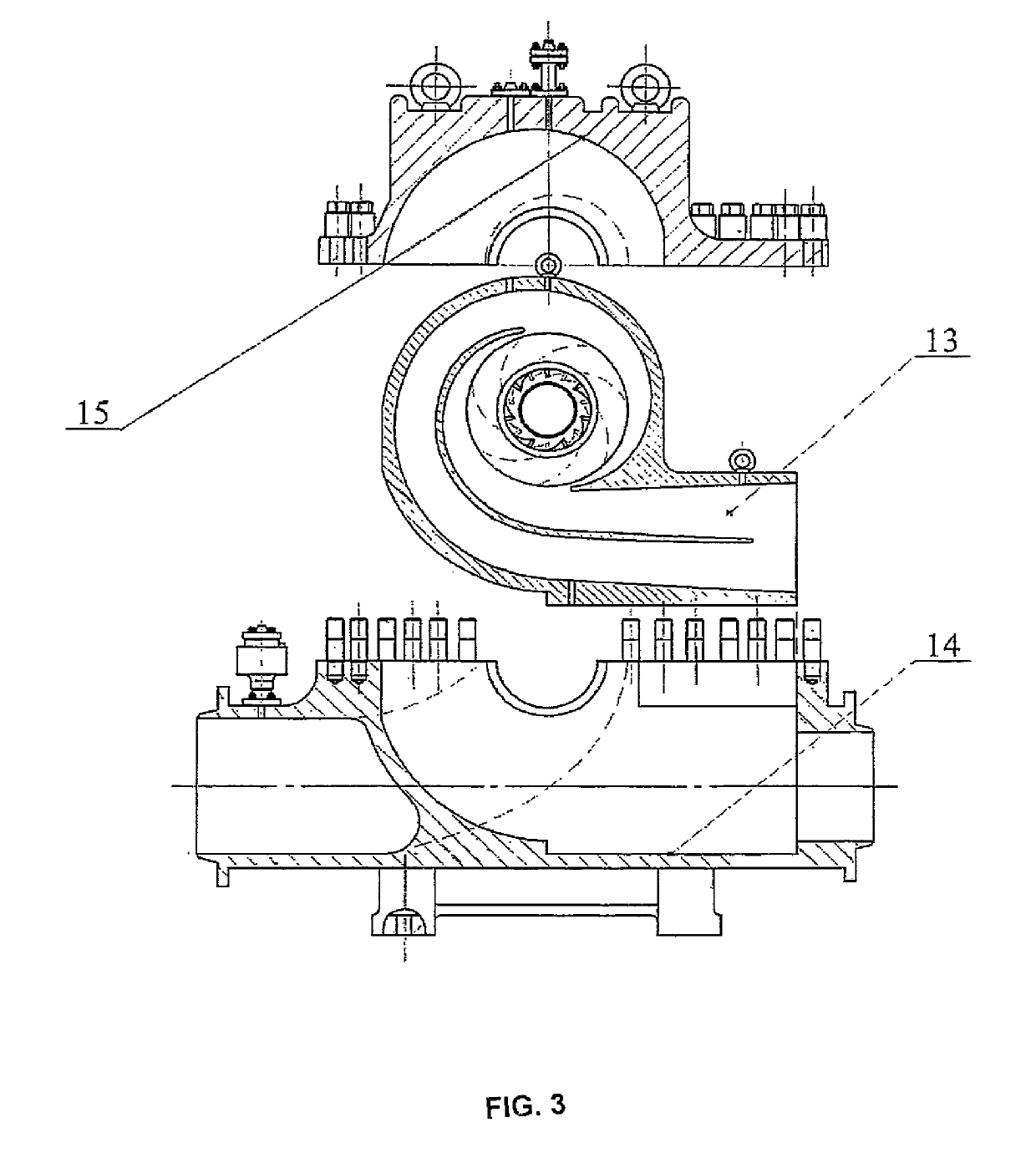

[0013]According to the present invention, a single-stage centrifugal pumping unit comprises an electric drive motor 2, a centrifugal single-stage double entry pump 1 (hereinafter, the pump), a coupling 3, connecting their shafts, a pump housing 17, which consists of a base 6 and a cover 7, an inlet manifold 8 and an outlet manifold 9, a rotor 10 with an impeller 11, the rotor being installed in support bearings 12, a volute 13, and a support frame 5 for mounting the pump housing 17 and the electric motor 2 thereon. As shown in FIG. 3, the volute 13 is configured in the form of a separate, independent component, and parts of the outside surface thereof, which are intended to be accommodated in cradles 14 and 15 provided for this purpose in the housing 6 and the cover 7, correspond to the shape of the surfaces of said cradles 14 and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com