Osteosynthesis device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

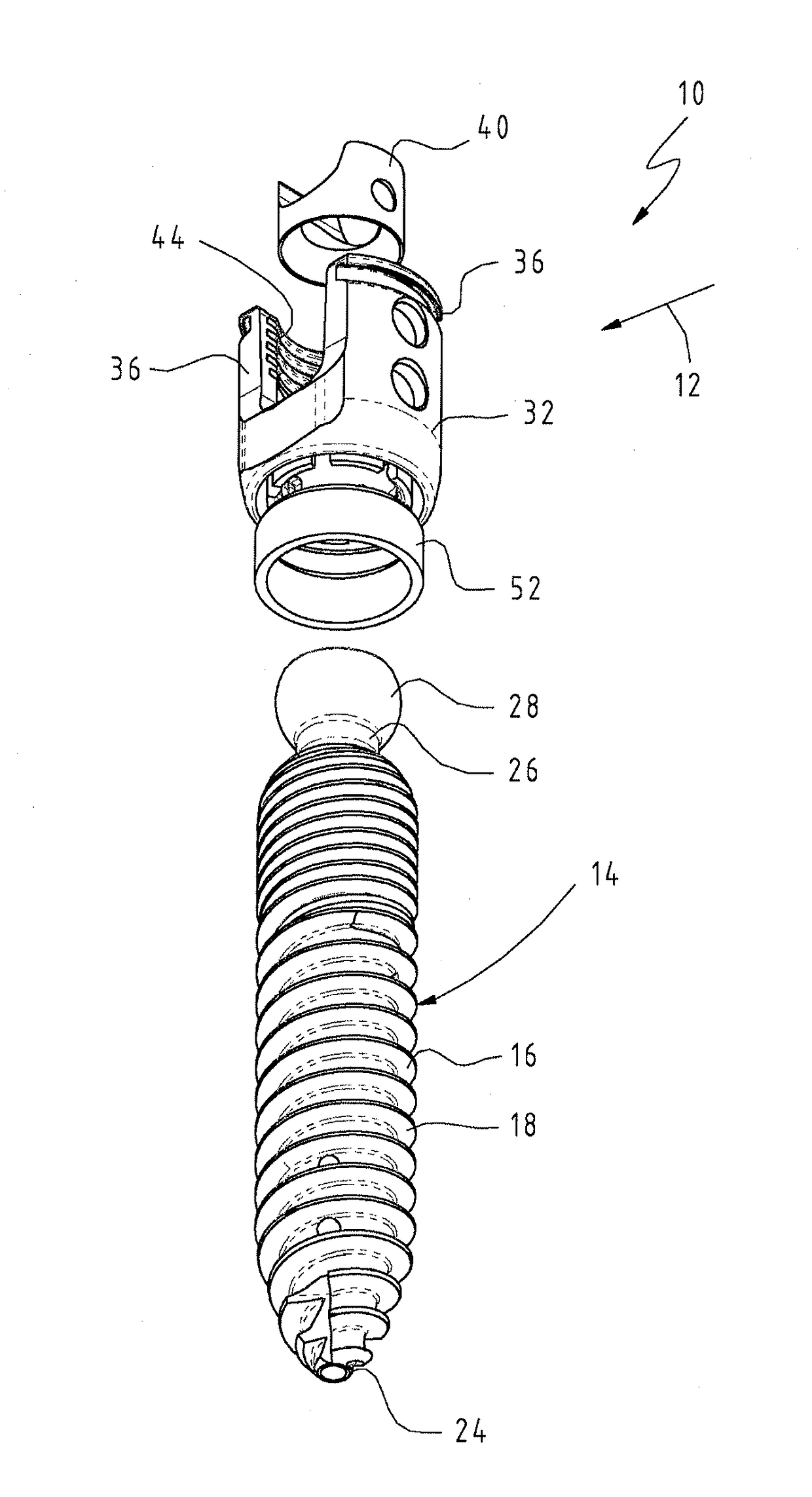

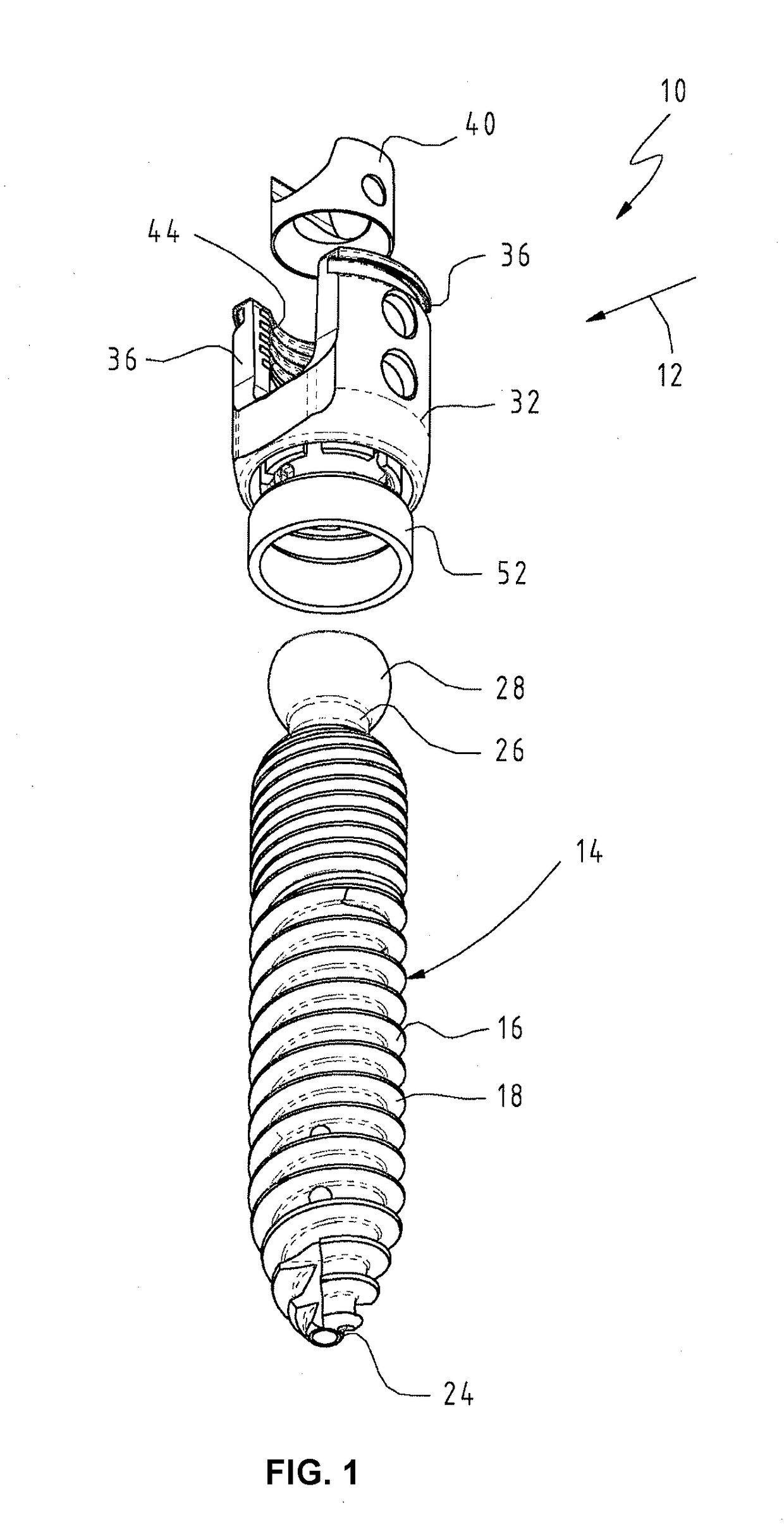

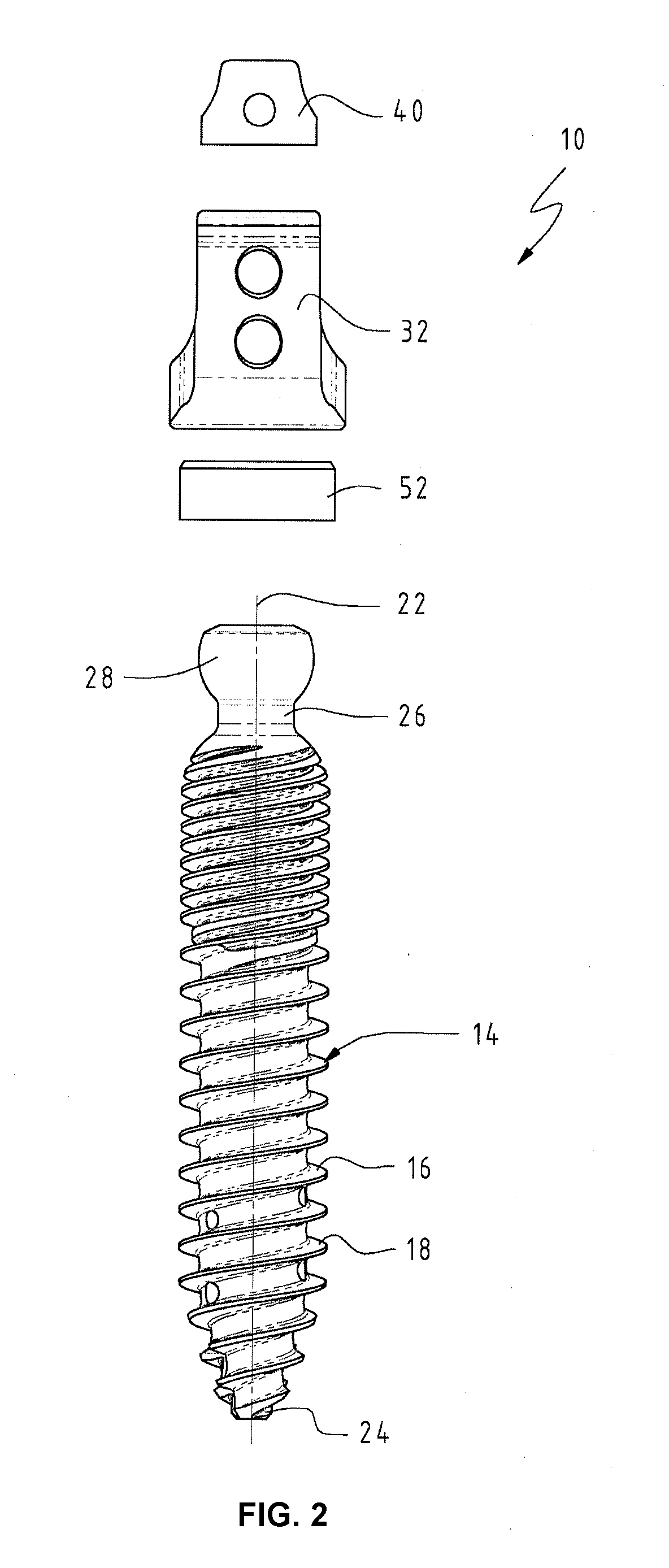

[0031]FIGS. 1 to 4 show an osteosynthesis device 10 according to the invention that is denoted as a whole by reference sign 10 and is designed as a pedicle screw, in particular as a polyaxial screw. Corresponding components and elements in the drawings are denoted by corresponding reference signs herein. FIG. 1 is an oblique view from below of the osteosynthesis device 10. FIG. 2 is an exploded side view of the osteosynthesis device 10 when viewed in the direction of the arrow 12 in FIG. 1. FIG. 3 is a non-exploded side view of the osteosynthesis device 10 according to FIG. 2 and FIG. 4 shows a section through the osteosynthesis device 10 along the line A-A according to FIG. 3.

[0032]The osteosynthesis device 10 comprises a bone anchor 14, designed as a bone screw, which comprises a shank 16 having an external thread 18. The bone anchor 14 or the shank 16 thereof is cannulated, i.e. it has a continuous longitudinal hole 20 that is concentric with a central longitudinal axis 22 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com