Leak Preventing Device and Tank for Transporting Liquid With such a Device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

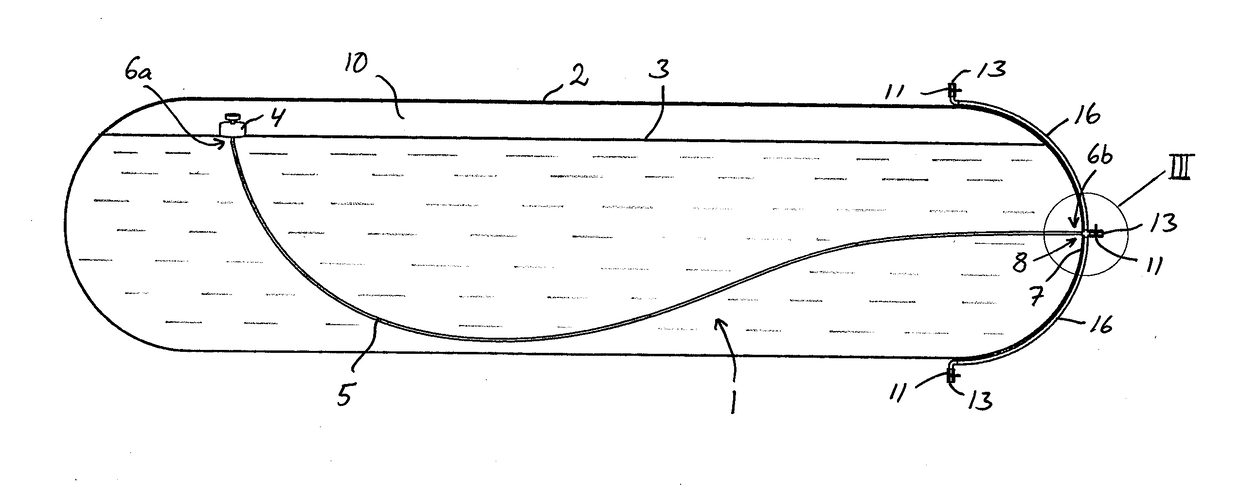

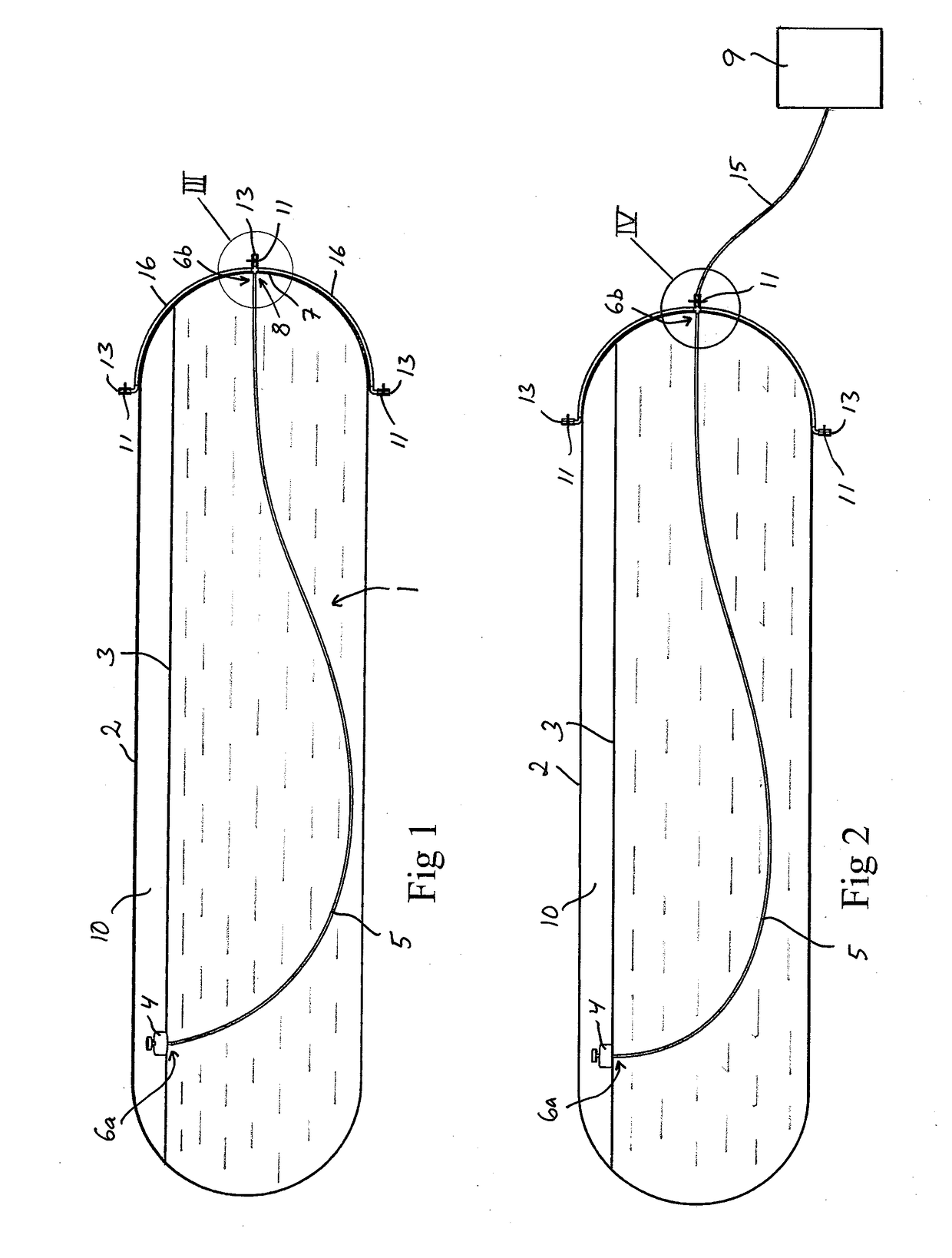

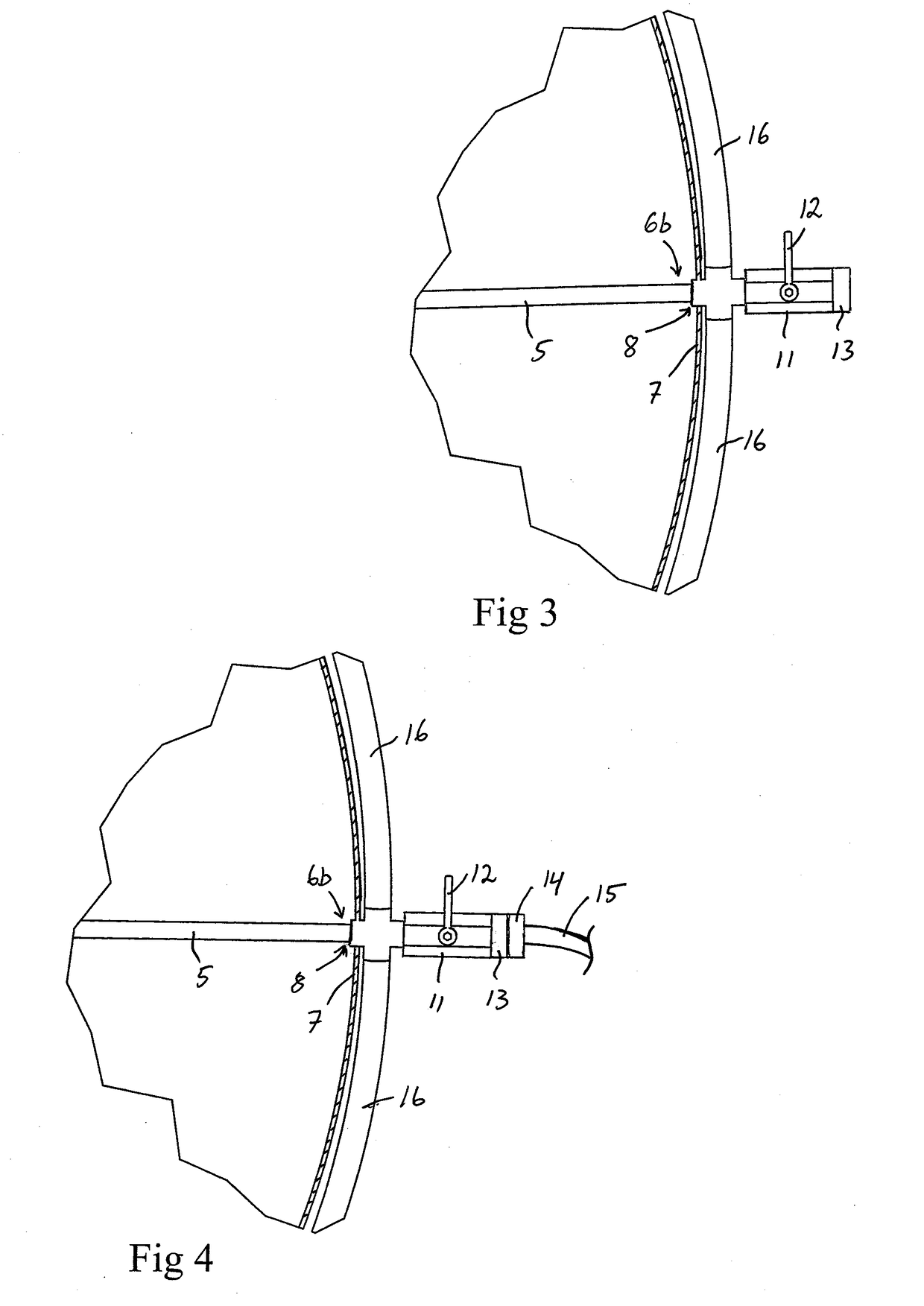

[0027]A leak preventing device 1 according to an embodiment of the present invention is schematically illustrated in FIGS. 1-4. The leak preventing device 1 is to be used with a tank 2 for transporting and / or storing liquid in order to prevent liquid from leaking out of the tank through a hole or crack in a wall of the tank below the surface 3 of the liquid in the tank if the tank is damaged due to an accident or wear. Thus, the leak preventing device 1 is to be pre-mounted to the tank 2 so as to be ready for use in a possible situation when the tank is damaged and liquid starts to leak out of the tank.

[0028]The leak preventing device 1 comprises a floating body 4 which is configured to have such a buoyancy that it is capable of floating at the surface 3 of the liquid in the tank 2 with at least an upper part of the floating body 4 located above the surface 3 of the liquid in the tank. The leak preventing device 1 also comprises a flexible hose 5 with a first end 6a and an opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com