High elongation ridge ventilation sheet for sloping roof and fabricating method therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention is illustrated in details in the figures and following embodiment. The embodiment is implemented based on the present invention but is not meant to limit the scope of the present invention.

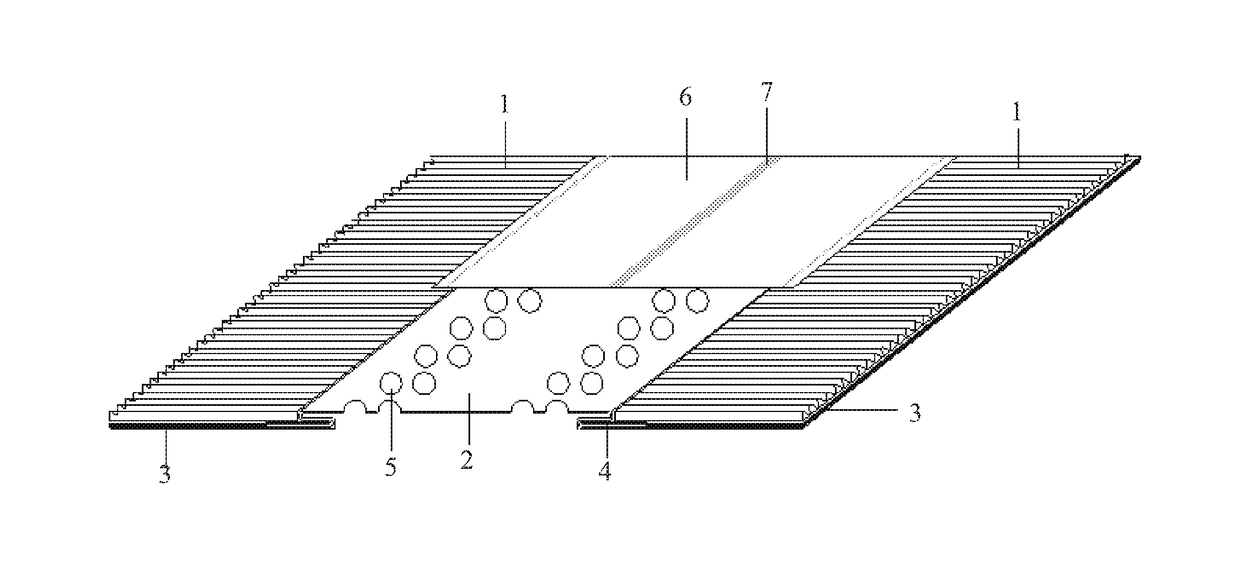

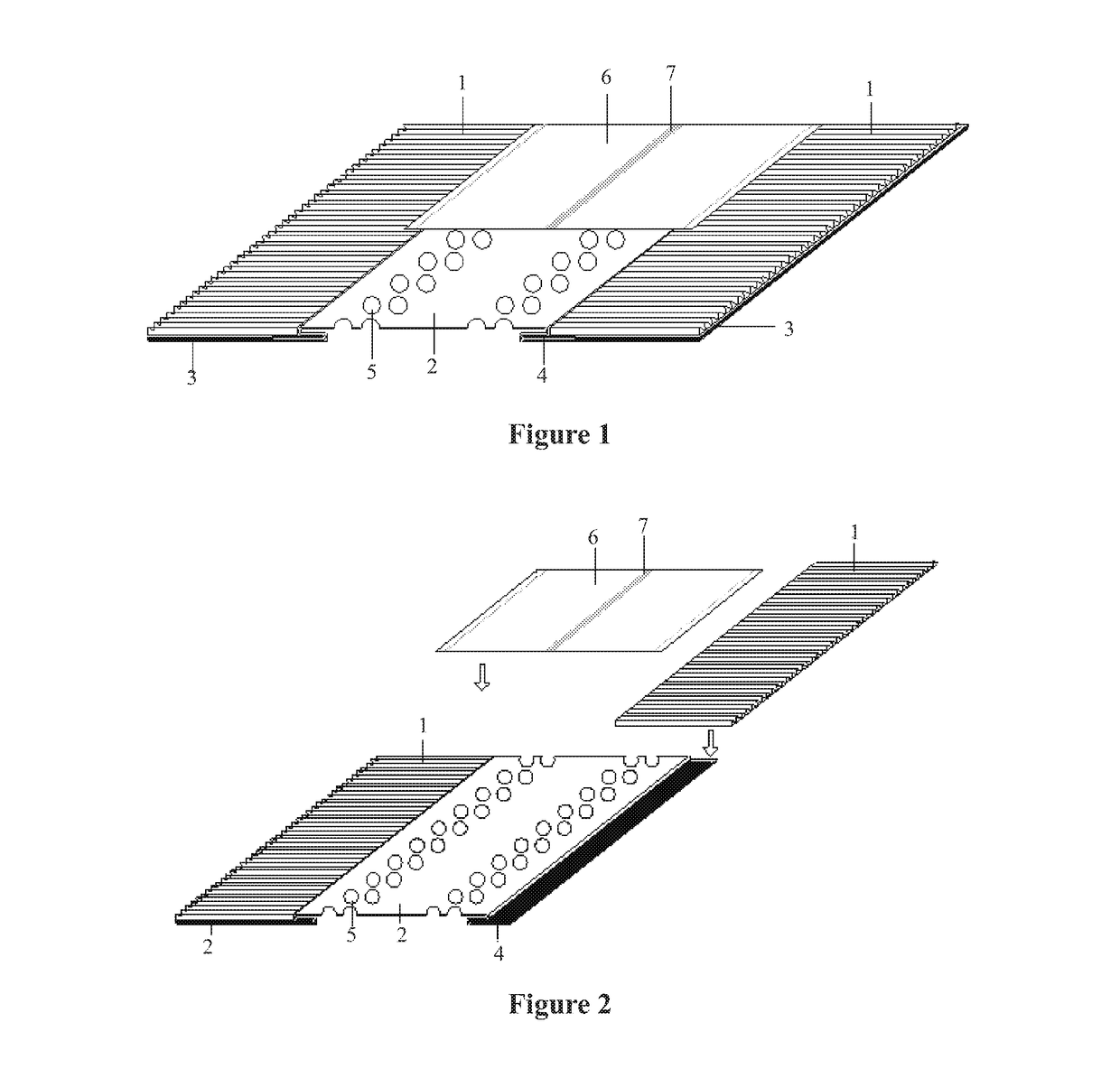

[0027]As shown in FIG. 1, a high elongation ridge ventilation sheet for a sloping roof has a coated composite aluminum membrane 2 with multiple circular holes 5, each side of the coated composite aluminum membrane 2 is bonded with a folded composite aluminum membrane 1 via a butyl adhesive tape for central linking 4 and forms a downward protruding bend. A hot melt adhesive for a polyester nonwoven fabric 6 is arranged on the surface of the polyurethane layer of each folded composite aluminum membrane 1 adjacent the coated composite aluminum membrane 2 for connecting to each folded composite aluminum membrane 1, and the polyester nonwoven fabric 6 covers the whole coated composite aluminum membrane 2. A side butyl adhesive tape 3 having a separator paper is arranged on e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com