Flame resistant viscose filter apparatus and method

a viscose filter and flame-resistant technology, which is applied in the direction of filtration separation, separation process, paper/cardboard containers, etc., can solve the problems of contaminating the hood and fan, affecting the filtration effect, so as to reduce the disadvantages and problems at least some of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

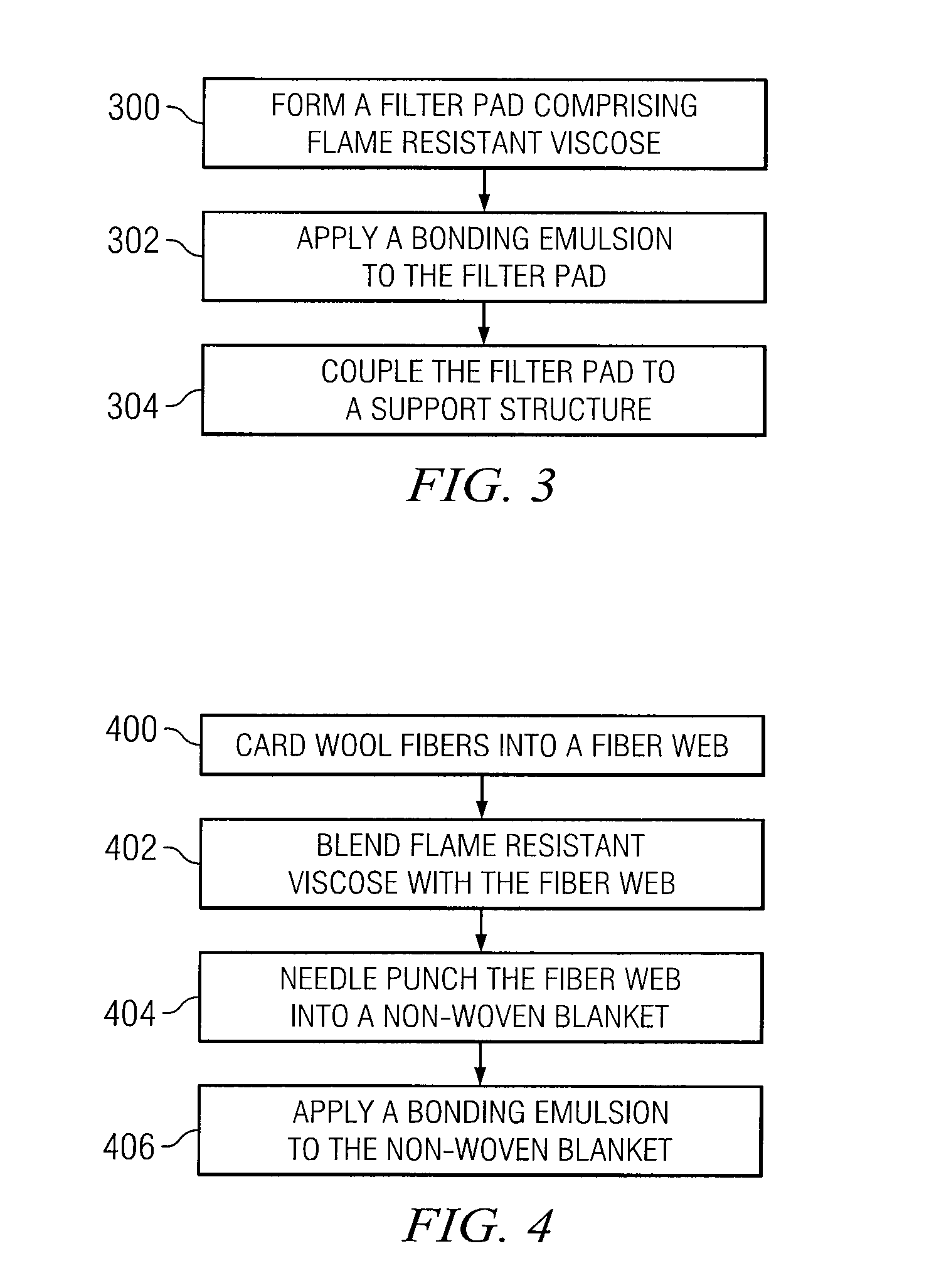

Method used

Image

Examples

Embodiment Construction

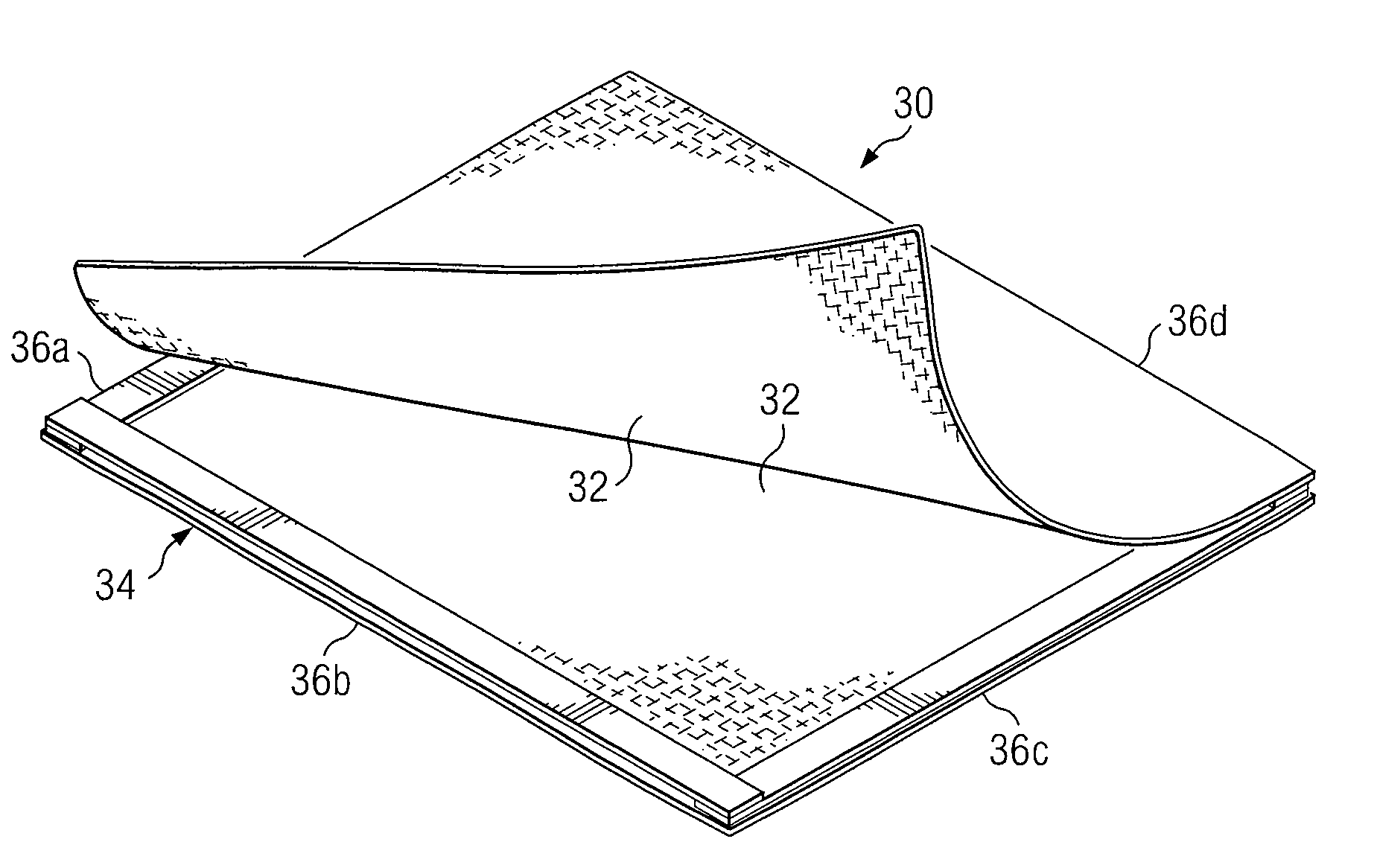

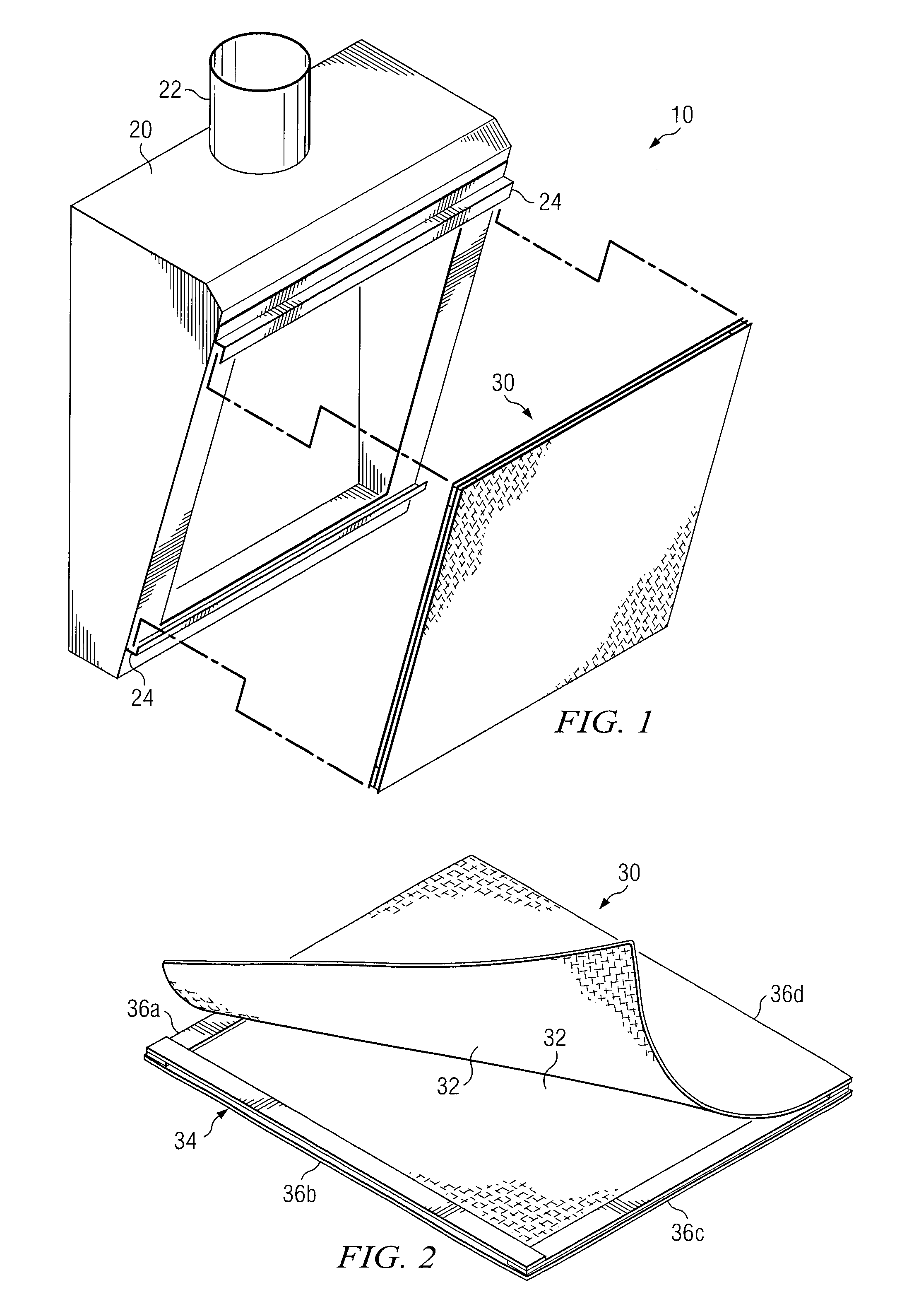

[0019]FIG. 1 illustrates a particular embodiment of an exhaust filtration system 10. Exhaust filtration system 10 may include vent hood 20 and filter assembly 30. To filter grease, vapor and other particulates arising from kitchen equipment, filter assembly 30 may be mounted in vent hood 20. In particular embodiments, filter assembly 30 may be formed of materials such that it is generally “self-supporting,” meaning that it does not require metal filter support frames, frame covers or heat shields. Filter assembly 30 can be formed in a variety of ways using a variety of materials that may result in a filter assembly 30 that is either reusable or disposable. In such embodiments, filter assembly 30 may be easily mounted, as discussed further below, in vent hood 20 by simply sliding it into place on brackets or some other similar fastening or support system within vent hood 20.

[0020]Vent hood 20 may represent any ventilation equipment designed or configured to exhaust heat, odors, greas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| fire resistant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com