Seed firming assembly for agricultural seeders and mounting system therefor

a seeding assembly and seed technology, applied in the field of agricultural seeding devices, can solve the problems of poor seedling emergence, low organic matter content, ineffective press from the soil surface, etc., and achieve the effect of improving the mounting arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

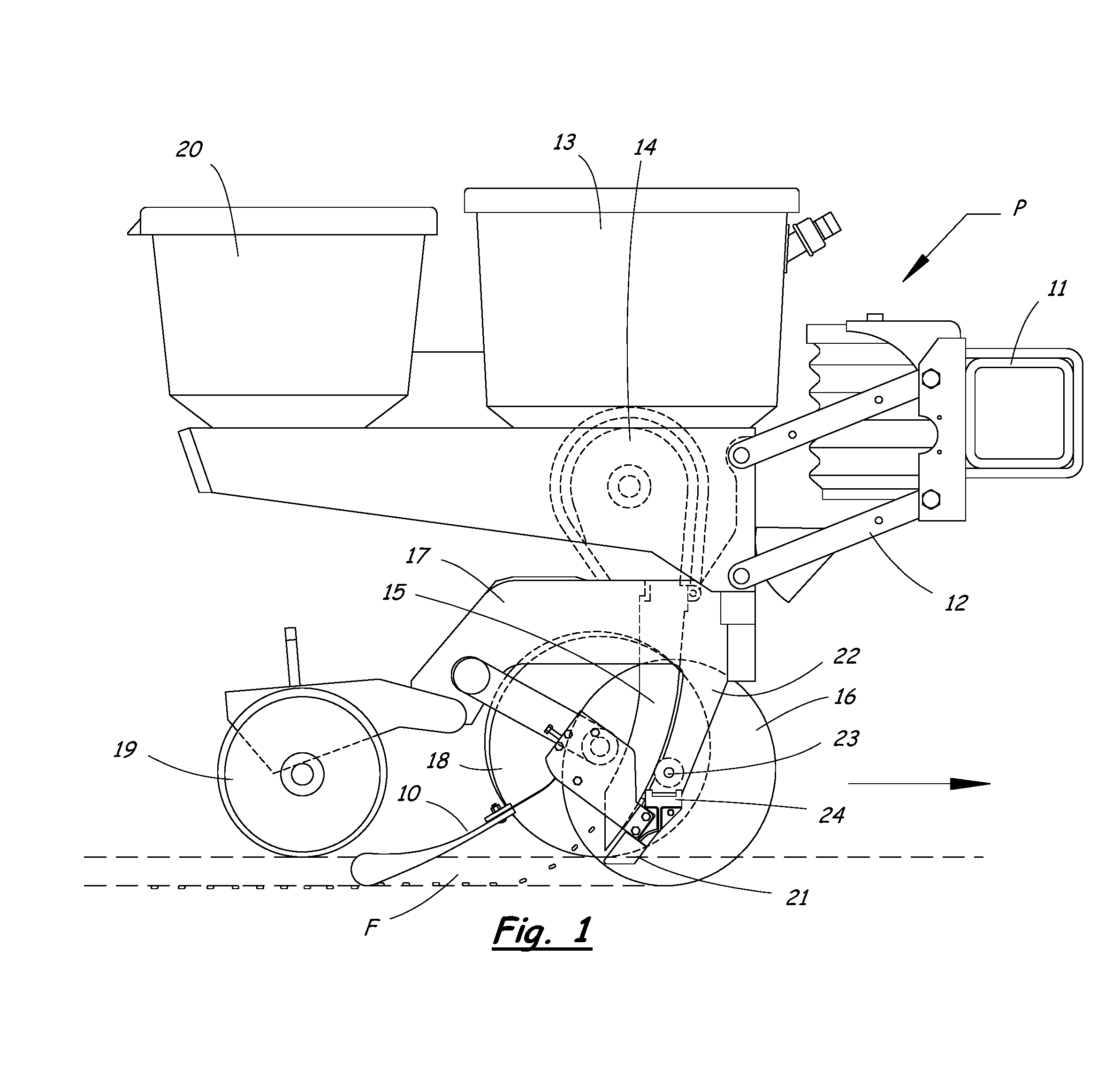

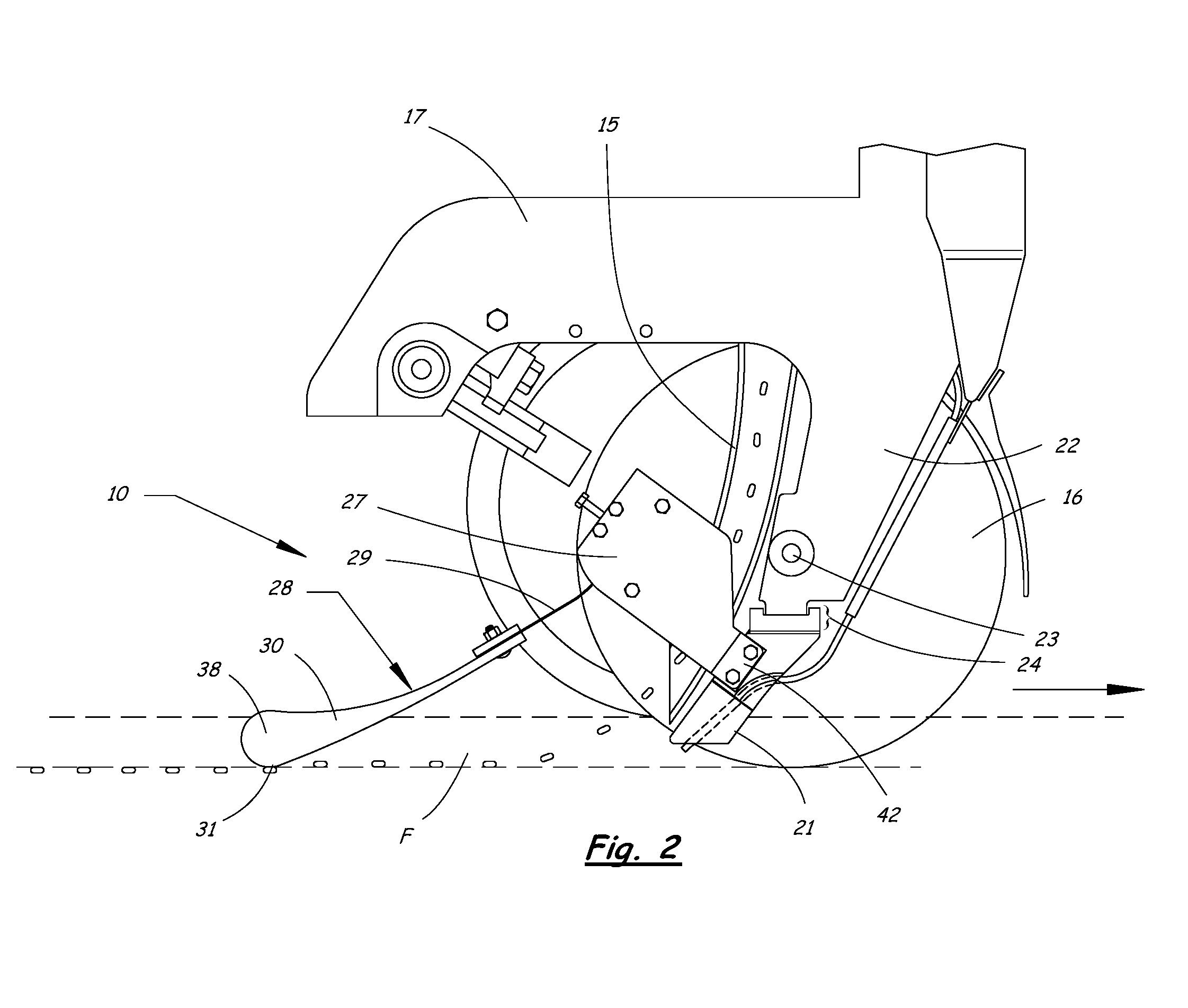

[0023]A seed firmer assembly 10 according to the present invention will now be described with reference to FIGS. 1 to 5 of the accompanying drawings.

[0024]FIG. 1 illustrates a planter row unit P attached to a transverse tool bar 11 by a parallel linkage 12 in a conventional manner. The planter row unit P has a seed bin 13 that holds a supply of seed, and a seed meter 14 at the bottom of the seed bin 13 that singulates and drops seeds into a seed tube 15 for placing the seeds in a seed planting furrow F. The seed planting furrow F is formed by a double disk furrow opener 16 attached to a shank 22 of a row unit subframe 17. Adjustable gauge wheels 18 attached to the subframe 17 control the depth of the furrow opener 16. A furrow closing assembly 19, such as a pair of closing wheels, follows behind the seed tube 15 and furrow opener 16 to close the furrow F and thereby cover the seed with soil. A pesticide bin 20 is also shown on the planter row unit P for applying pesticides, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com