Shoe Lasts For Use With Conformable Booties, Shoe Inserts, Footwear Assemblies and Waterproof Breathable Socks

a technology for conformable booties and shoe inserts, applied in the field of unique shoes, can solve the problems of poor fitting shoes, less than desirable appearance of the inside of the shoe, and difficulty in sewing the functional layer directly to the upper and/or sole material of the shoe, so as to improve the comfort of wear for users, reduce and even eliminate air gaps, and enhance breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

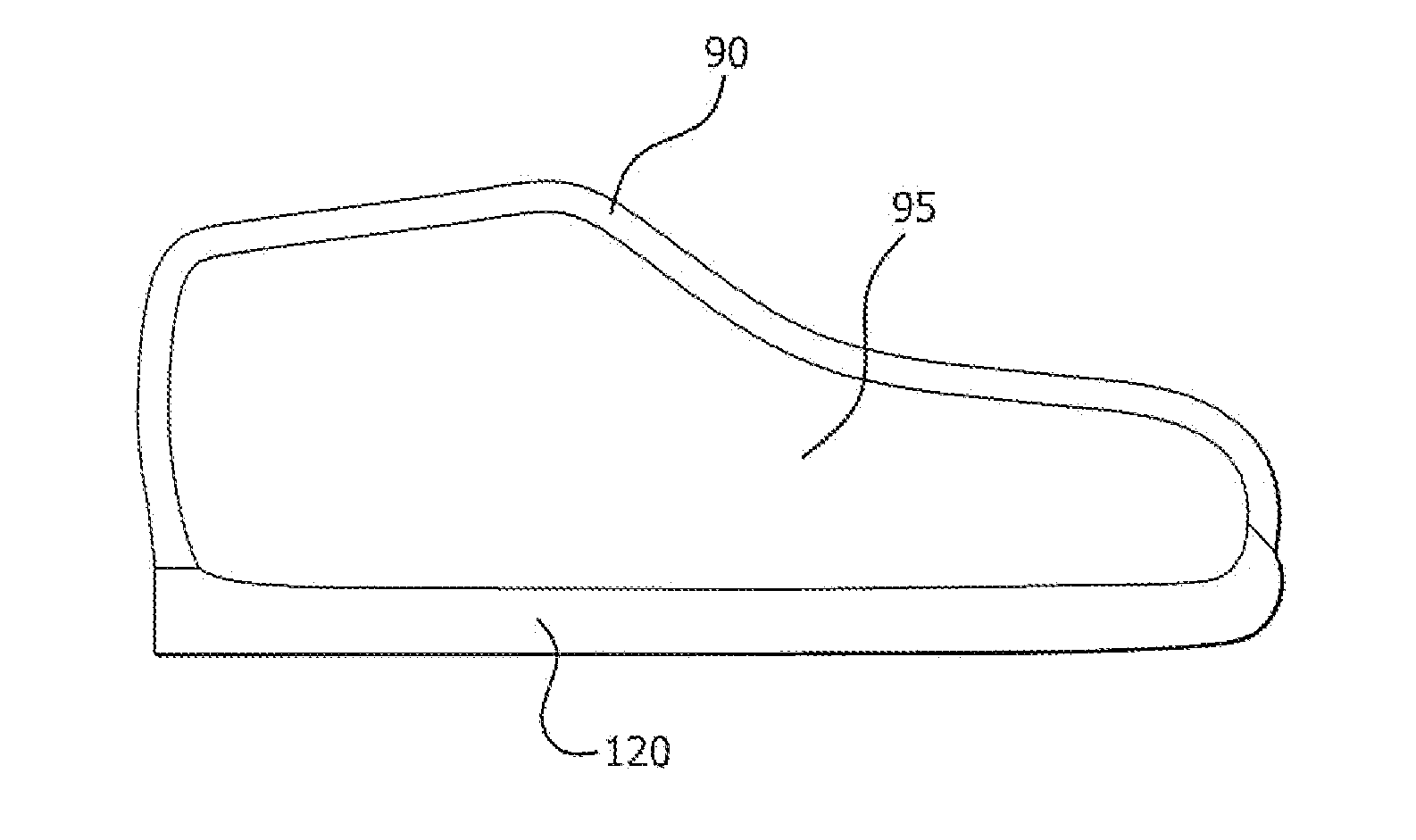

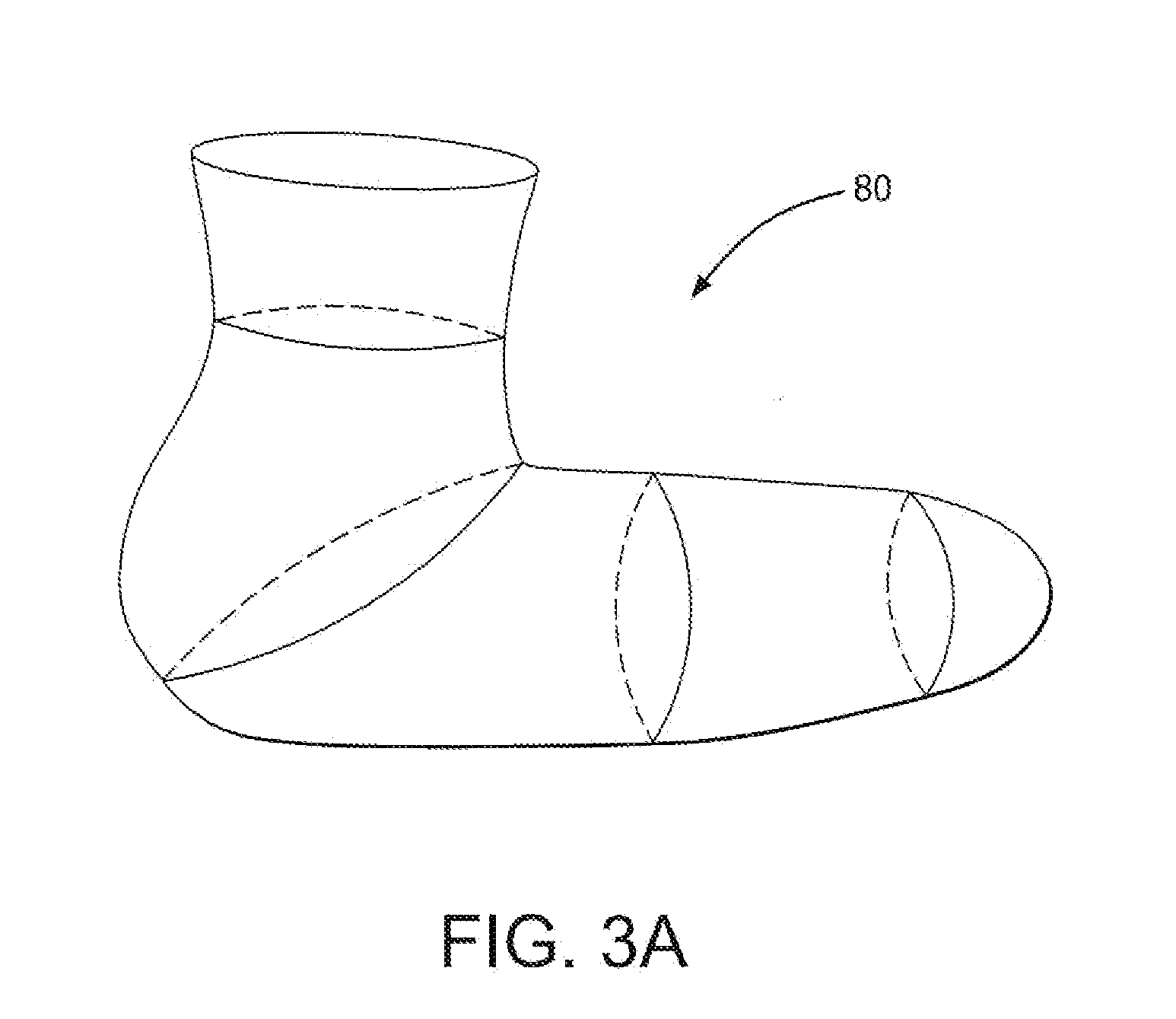

[0201]A symmetrical cast aluminum foot last having a shape as depicted generally in FIG. 3 was fixed onto a clamp which can rotated through an angle of approximately 140° using a pneumatic cylinder. A polyurethane adhesive web (UT8, 20 g / m2 polyurethane non-woven hot melt adhesive commercially available from Protechnic, 41 Avenue Montaigne, F-68700, Cernay, France) was applied to one side of a commercially available 30 denier (33 dtex) 100% Polyamid black sock (Knie 30 Leicht deckend obtained from the Nur Die GmbH, Rheine, Germany) using a heat press set at 130° C. and effective pressure of 5 psi. The sock with the polyurethane adhesive web thereon was positioned tightly over the last. The sock was applied to the last with the adhesive web exposed on the outer surface of the last. Care was taken when applying the sock to the last to avoid wrinkles.

[0202]A fine powder of PTFE polymer (Daiken Industries, Ltd., Orangeburg, N.Y.) was blended with Isopar® K (Exxon Mobil Corp., Fairfax, V...

example 2

[0208]A symmetrical nylon foot last having a shape as depicted generally in FIG. 3 was fixed onto a clamp which can be rotated through an angle of approximately 140° using a pneumatic cylinder. A polyurethane adhesive web (UT8, 20 g / m2 polyurethane non-woven hot melt adhesive obtained from Protechnic, 41 Avenue Montaigne, F-68700, Cernay, France) was applied to one side of a commercially available 60 den (66 dtex) 61% polyamide, 37% cotton, and 2% elastane black sock (Sockchen Naturelle 60 obtained from the Nur Die GmbH, Rheine, Germany) using a heat press set at 130° C. and an effective pressure of 5 psi. The sock with the polyurethane adhesive web thereon was positioned tightly over the last. The sock was applied to the last with the adhesive web exposed on the outer surface of the last. Care was taken when applying the sock to the last to avoid wrinkles.

[0209]A portion of the expanded PTFE tape produced in Example 1 having a length of approximately 1 meter and a width of approxim...

example 3

[0215]A 2-layer bootie was produced in the same manner as Example 2. A 2-layer shoe insert was then thermally shaped by loosely placing the bootie onto a conventional men's 265 running shoe last with the expanded PTFE membrane layer exposed on the upper surface and heating the precursor in an air circulating oven at 140° C. for 30 min. During this thermal dwell, the shoe insert closely conformed to the shape and size of the conventional, asymmetrical last, thereby forming a smooth and close fitting shoe insert to the last. The last was removed from the oven and allowed to cool to less than 50° C., after which the two-layer shoe insert was removed from the conventional, asymmetric last.

[0216]The three-dimensional shoe insert was then tested for water vapor permeability (breathability) using the Whole Boot Moisture Vapor Transmission Rate test method outlined above with the expanded PTFE membrane layer exposed on the upper surface. The average water vapor permeability was determined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com