Effect pigments

a technology of effect pigments and pigments, applied in the field of effect pigments, can solve the problems of inadequate hiding power of effect pigments, inadequate color saturation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

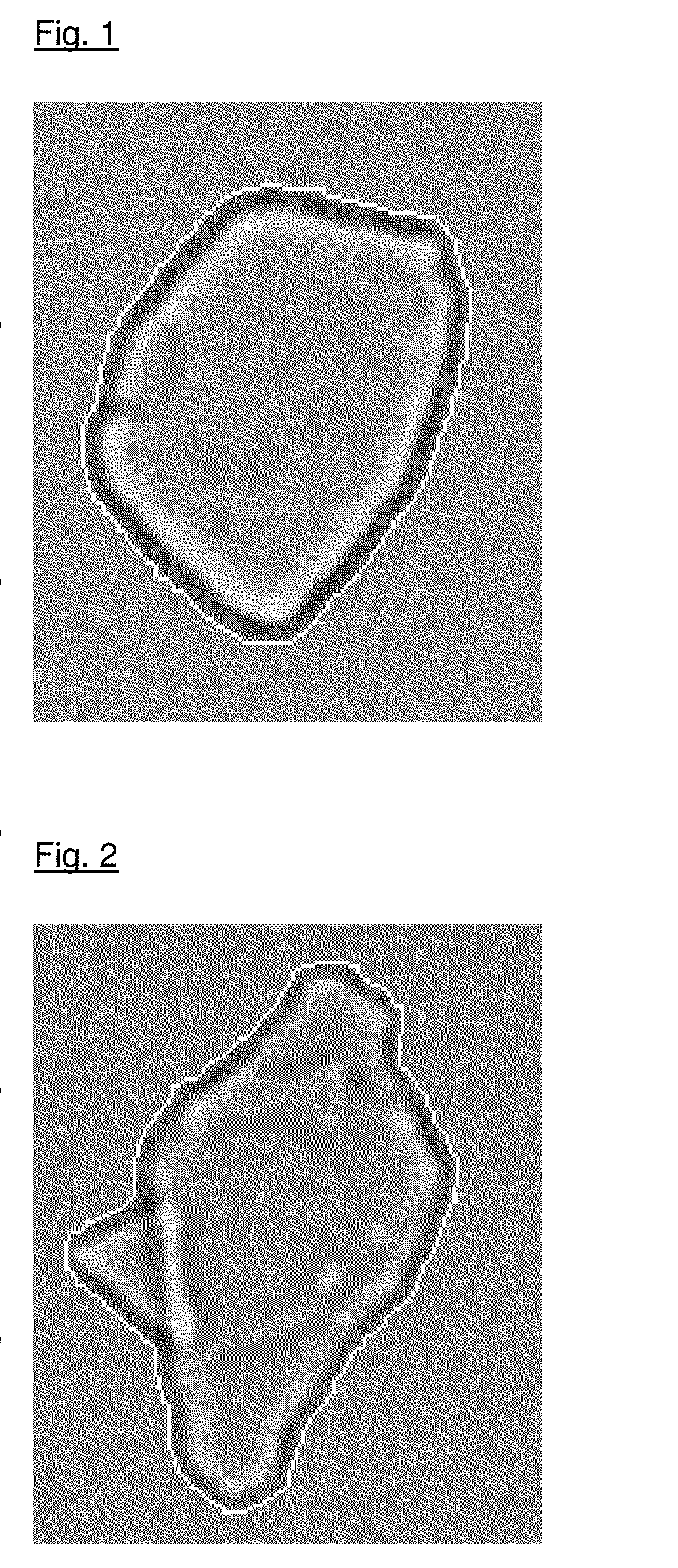

Image

Examples

example 1a

[0157]1 kg of Muscovite mica, which is in the form of coarse flakes, is ground to a particle size of less than 200 μm by a Koller process. The fine mica flakes formed in this way are introduced into a rotor-stator mill, and 1 l of deionized water is added. The resultant suspension is ground in the mill for 5 hours, during which the surface of the flakes is polished smooth at the same time. The mechanical loading of the particles during the grinding step is selected so that a permanent shear results in further gentle delamination of particles and in smoothing of the edges and surfaces. A narrow particle-size distribution is achieved by a subsequent classification step in the form of a plurality of (at least 3 steps) sedimentation steps. The mica flakes produced in this way have a particle-size distribution of 10-40 μm, a thickness distribution of 0.2 to 0.6 μm (in each case 90% of all particles) and a smooth-polished surface having only few sharp edges. The circular form factor is 1....

example 1 b

[0158]1 kg of synthetic mica flakes is treated analogously to Example 1a. Synthetic mica flakes having a circular form factor of 1.6 are obtained.

II. Coating of the Substrate Flakes

example 2.1

Natural Mica+SnO2+TiO2

[0159]100 g of natural mica flakes from Example 1a are warmed to 75° C. in 2 l of deionized water with stirring. The coating pH of 1.8 is established by dropwise addition of an SnCl4 solution (22 g / l). The remainder of 100 ml of SnCl4 solution (22 g / l) is subsequently metered in. During this addition, the pH is kept constant at 1.8 using 32% sodium hydroxide solution. When the addition is complete, the mixture is stirred for a further 10 minutes.

[0160]At constant pH, 490 ml of a TiOCl2 solution (400 g of TiCl4 / l) are then metered in until the color end point (yellow) has been reached, during which the pH being is constant at 1.8 by simultaneous dropwise addition of 32% sodium hydroxide solution.

[0161]When the addition is complete, the mixture is stirred for a further 10 minutes, the suspension is filtered off with suction and washed with deionized water until salt-free. After drying at 120° C. (24 h), the pigment is calcined at 800° C. for 45 minutes.

[0162]A h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com