Recoil Reducing Spring System

a spring system and coil technology, applied in the field of coil reducing mechanisms, can solve the problems of uncontrollable recoil force, undesirable muzzle lift, and shooter injury, and achieve the effect of less recoil and muzzle lift, and reducing the impact of buffer to buffer tub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

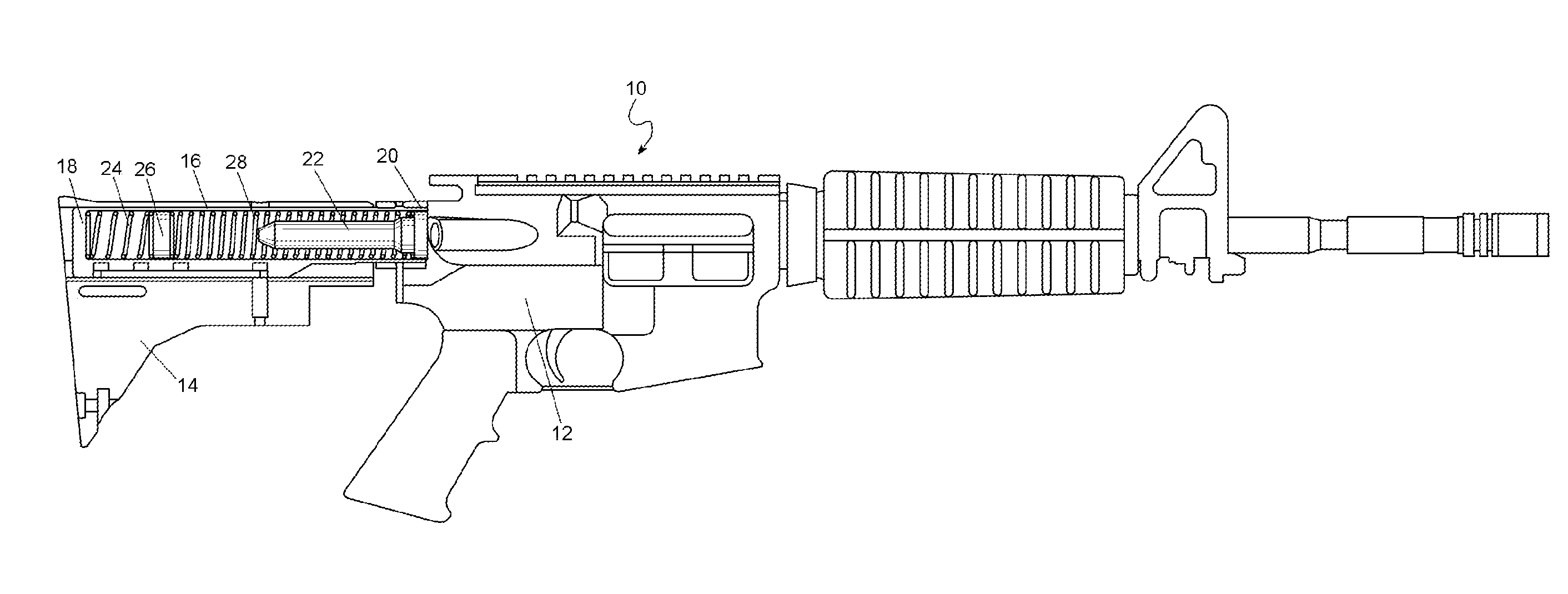

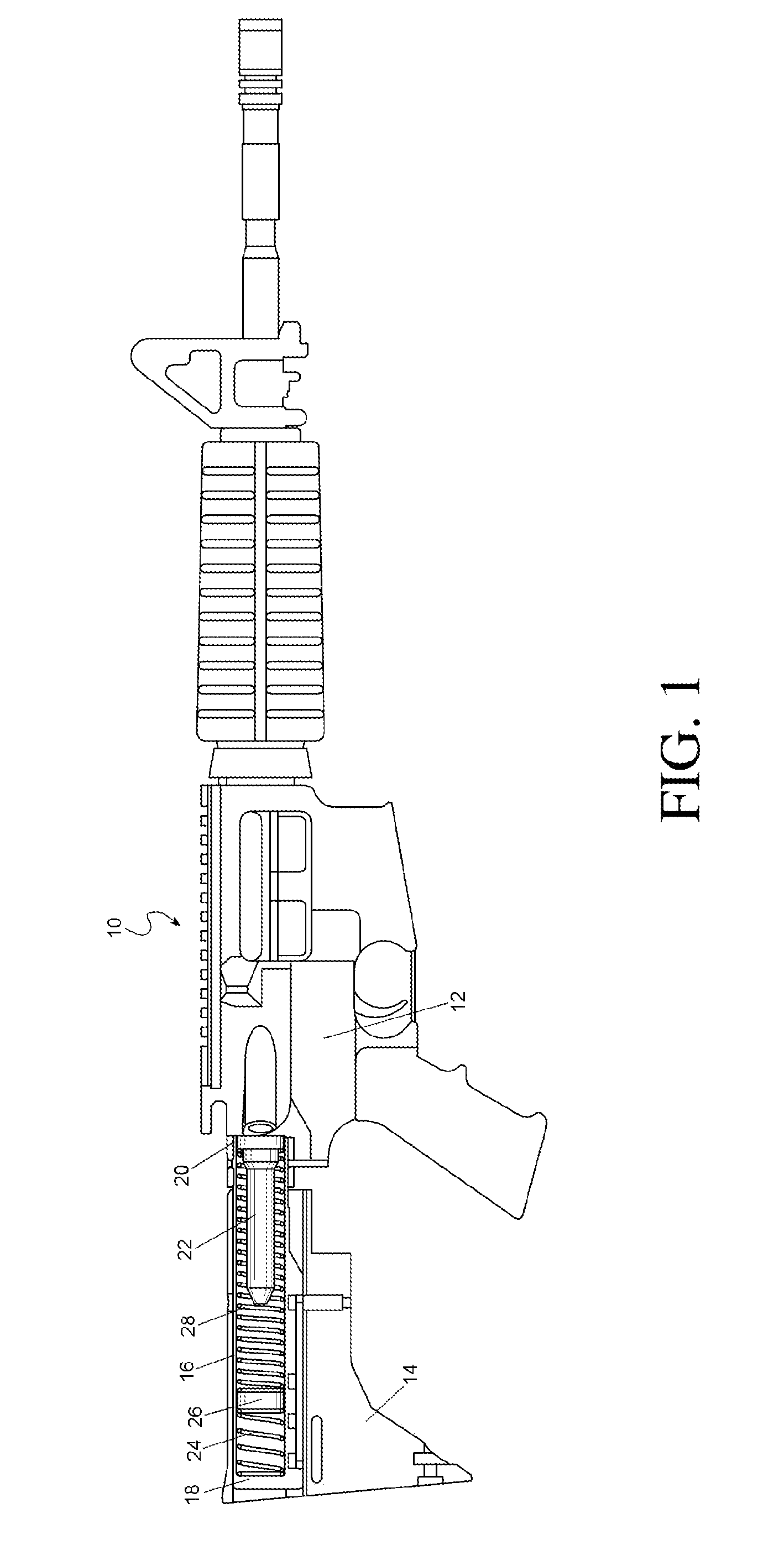

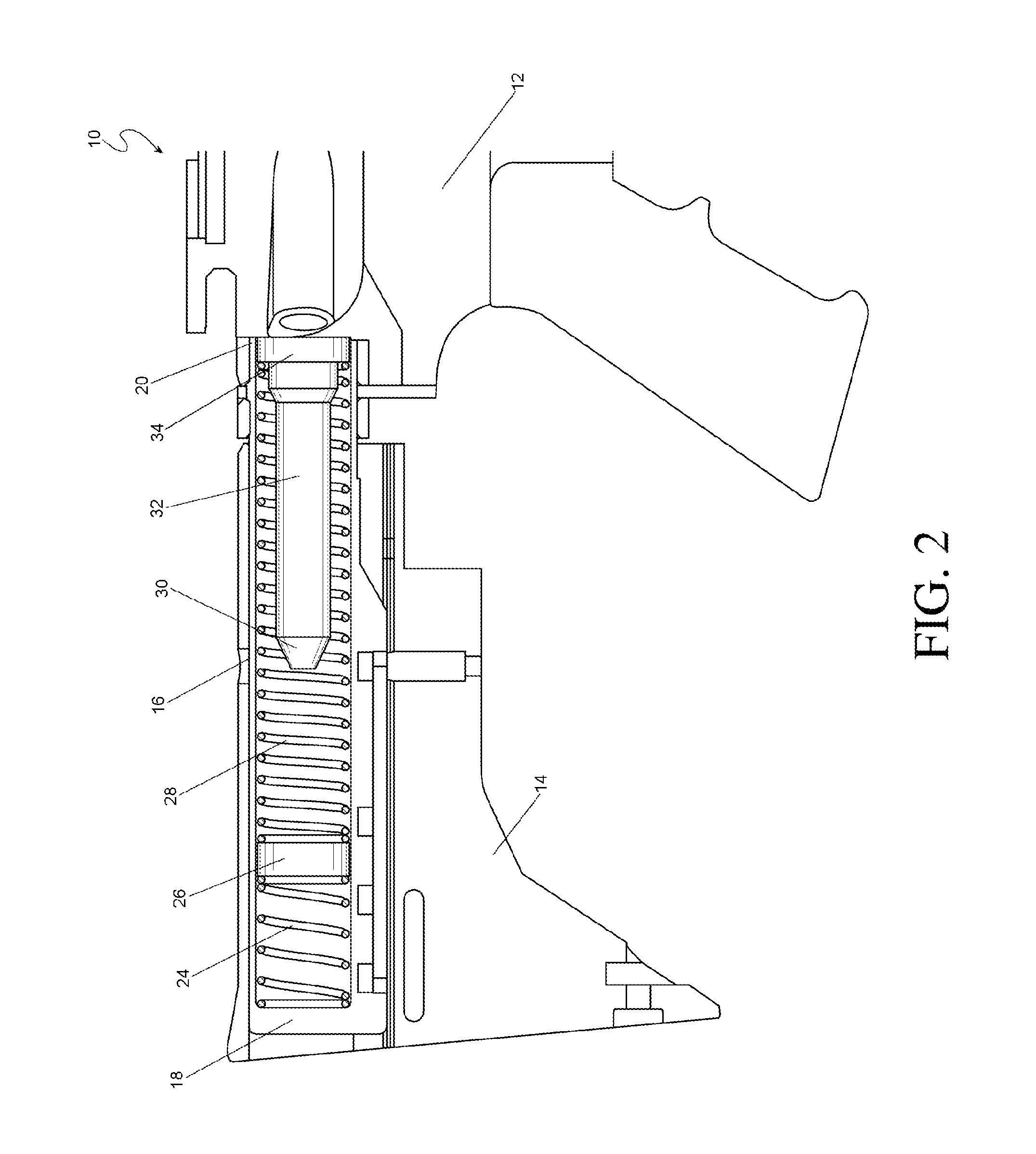

[0013]FIG. 1 illustrates a firearm 10 in the M16 family, such as an AR-15, shown from the side comprising a receiver 12 with a buttstock 14 attached to the rear of the receiver 12. The buttstock 14 contains a buffer tube 16 having a closed end 18 and an open end 20 which is shown cut away in FIGS. 1 and 2. The buffer tube 16 is attached to the receiver 12 at its open end 20. Contained within the buffer tube 16 is a buffer 22 along with the preferred embodiment of the recoil reducing spring system comprising: a short spring 24, a spacer 26, and a long spring 28. The buffer 22 comprises a small bumper end 30, a buffer body 32, and a larger stepped end 34 that is positioned within the long spring 28 at the opposite end from the spacer 26. FIG. 3 illustrates the components contained within the buffer tube including: the short spring 24, the spacer 26, the long spring 28, and the buffer 22.

[0014]The short spring 24, spacer 26, and long spring 28, which comprises the recoil reducing sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com