Expanded Metal LWO

a metal lwo and metal technology, applied in the field of expansion of metal lwo, can solve the problems of product failure to take water, and poor performance of lwo patterns/overlain by screens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

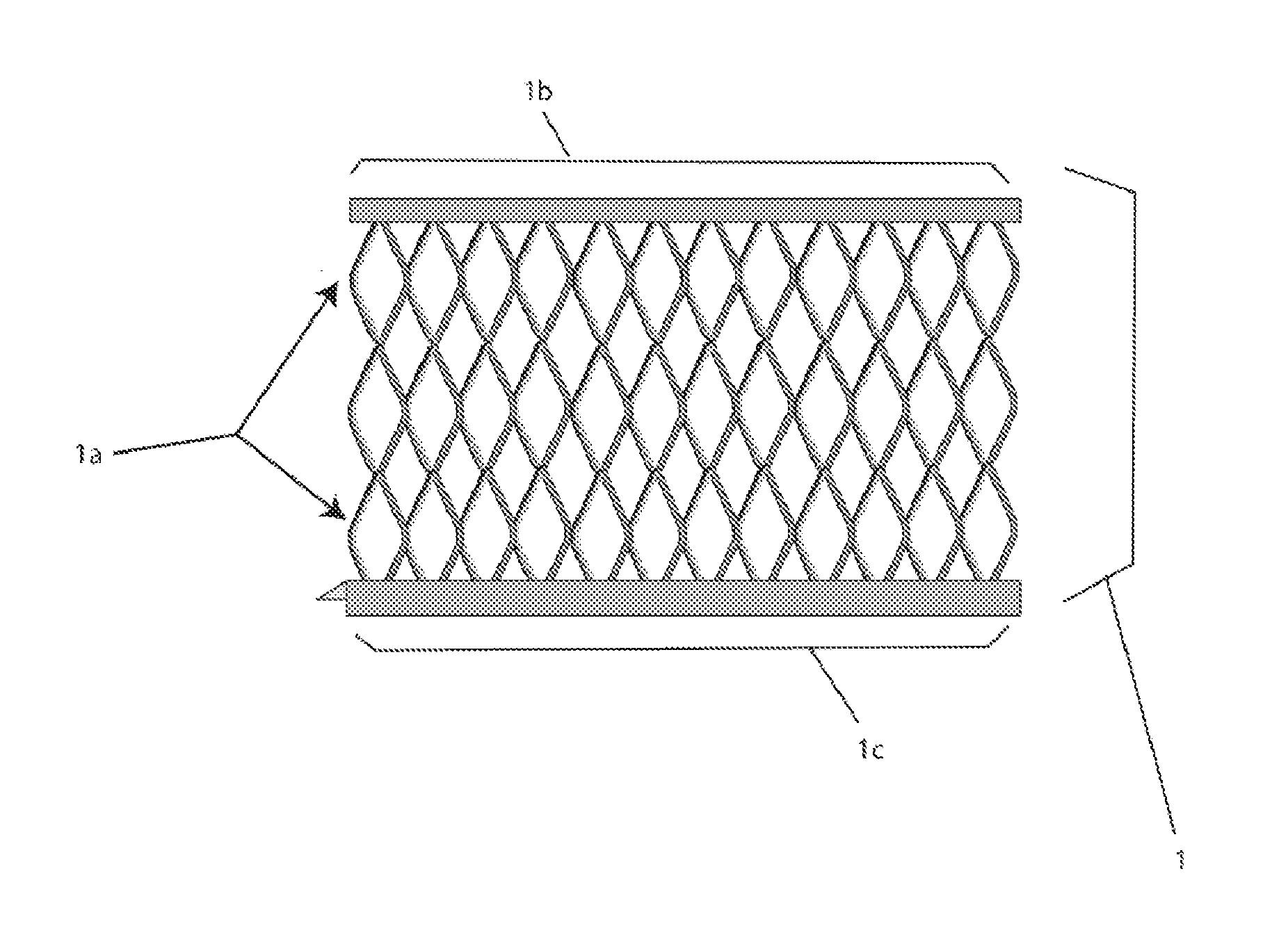

Image

Examples

Embodiment Construction

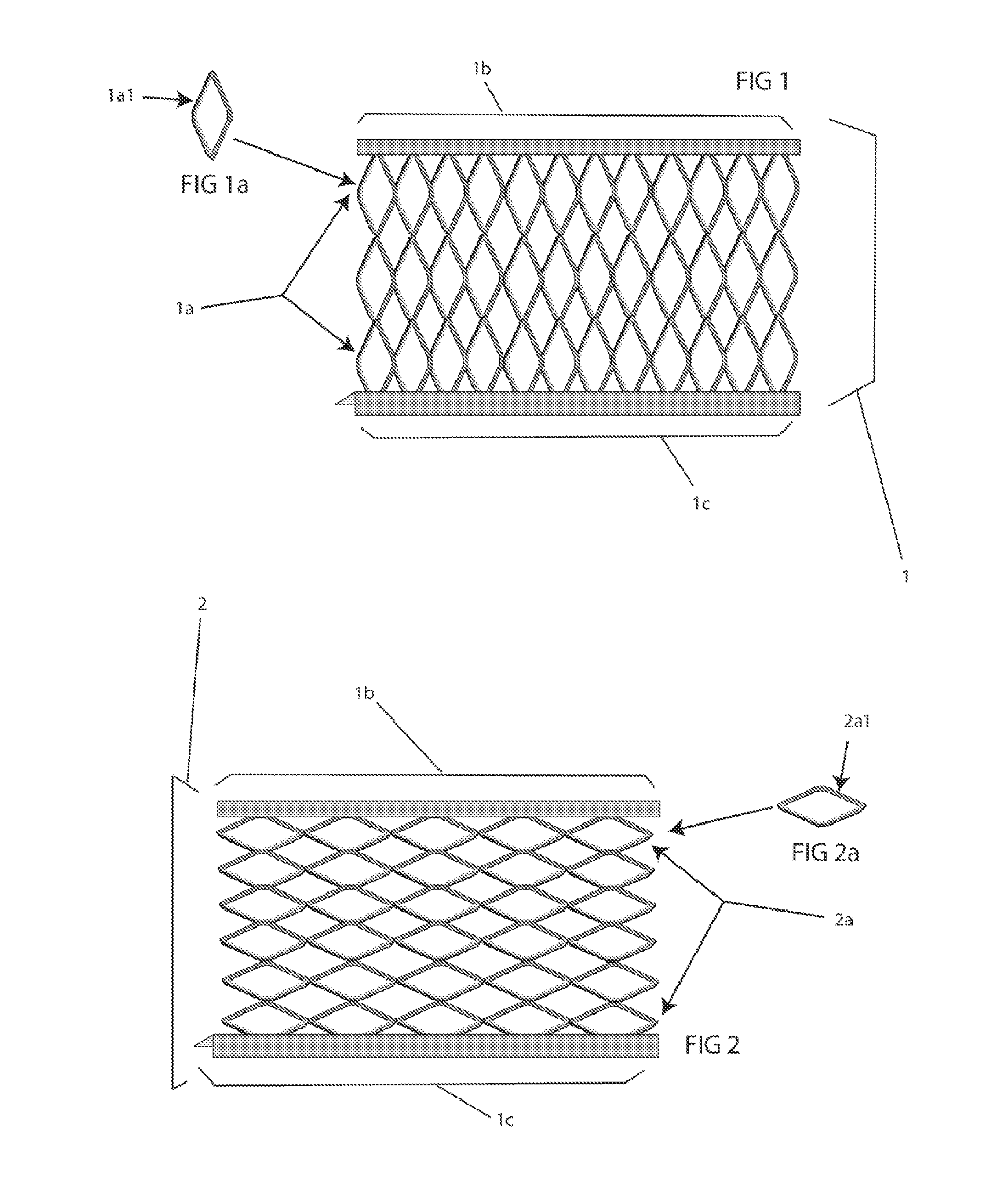

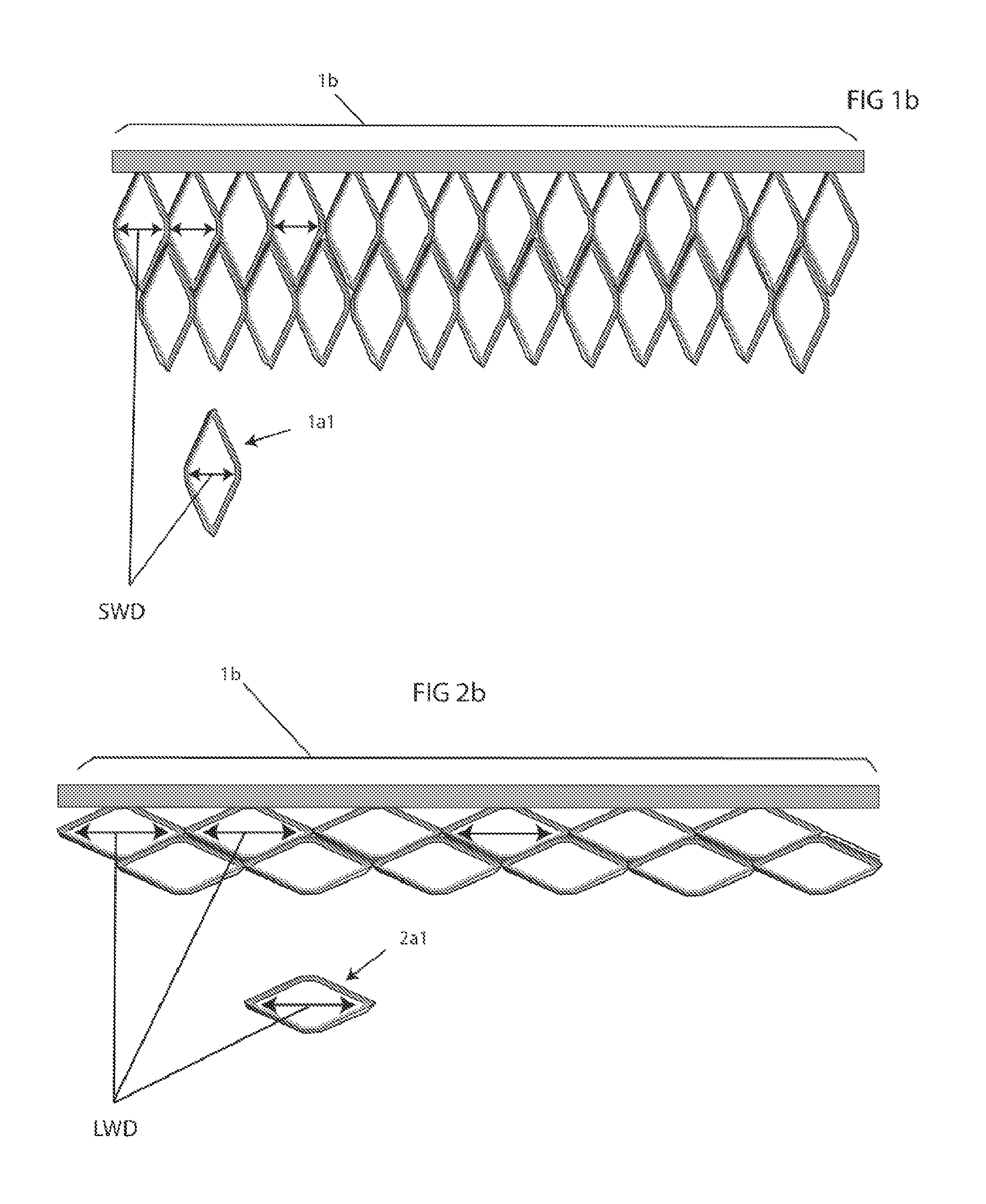

[0087]Referring to FIG. 2b this embodiment teaches the utilization of expanded metal that employs openings whose longest measured air space 2a1 is longitudinally parallel to the longest edge 1b of the sheet or roll of the expanded metal they exist within and whose sidewall members are angled upward from the original plane of metal they have been created from. This allows for the expanded metal to be placed over a rain gutter in such a manner that each sidewall member, or the majority of sidewall members, of each punched opening is facing the oncoming flow of water off of a roof structure. Expanded metal exists as both “flattened” in which the sidewall members are flat; not angled, and as “standard” or “angled side wall members”. The present invention employs “Standard” expanded metal that is then coupled with a “sheer” filtering overlay for the purpose of preventing debris entrance into a gutter while redirecting water flow into a rain gutter.

[0088]Referring to FIG. 1b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com