Axial-flow fan

a technology of axial flow and fan blade, which is applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of narrowing of a space and the possibility of molding failure in the outer perimeter portion of the blad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

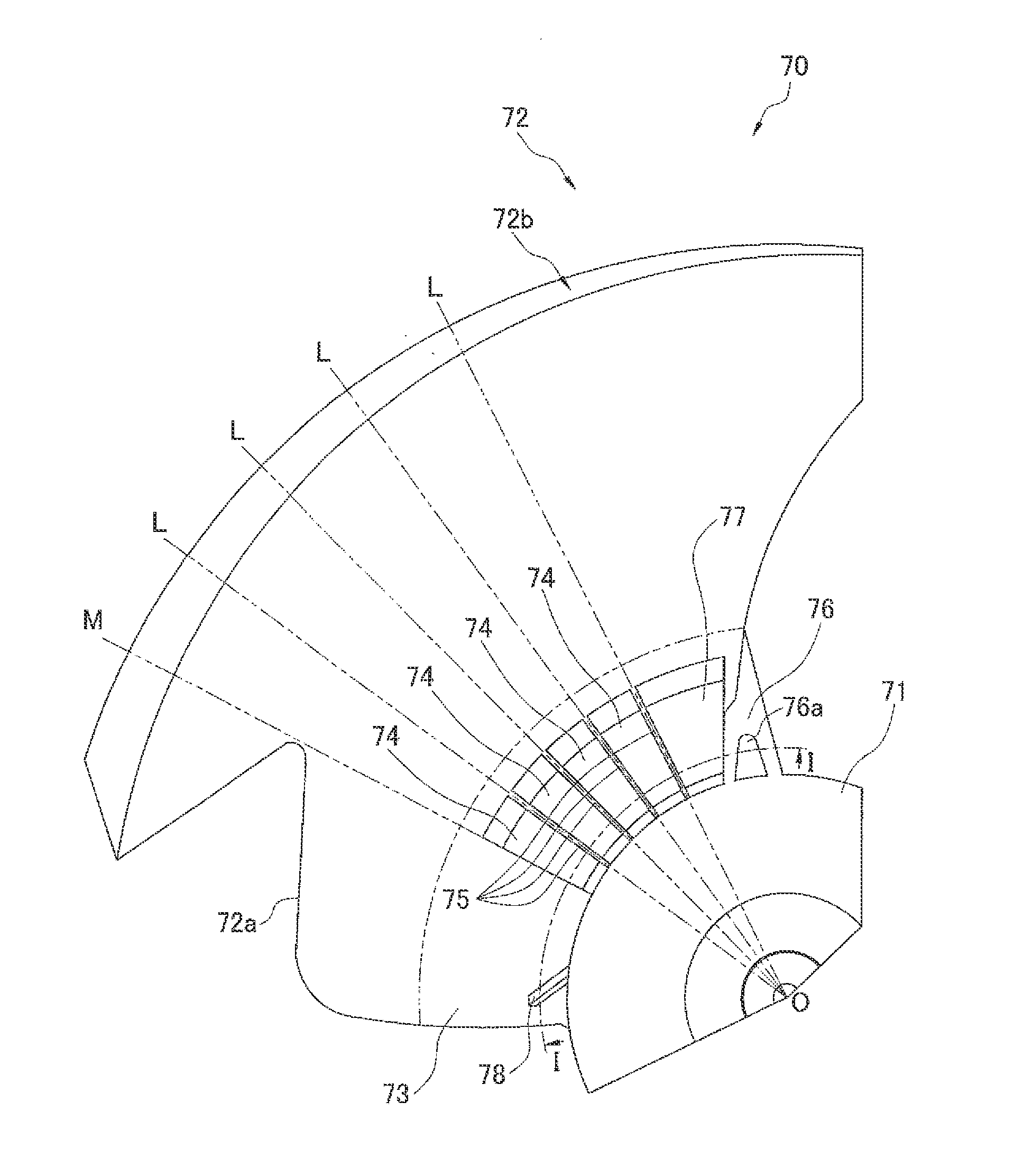

[0038]An embodiment of the axial-flow fan according to the present invention is described below based on the accompanying drawings. The specific configuration of the axial-flow fan according to the present invention is not limited to the embodiment below, and modifications are possible within a scope not deviating from the main point of the present invention. In the description below, an example in which the present invention is applied to an axial-flow fan configuring an outdoor unit is described, but the present invention is not limited to this; it may be applied to an axial-flow fan for another use.

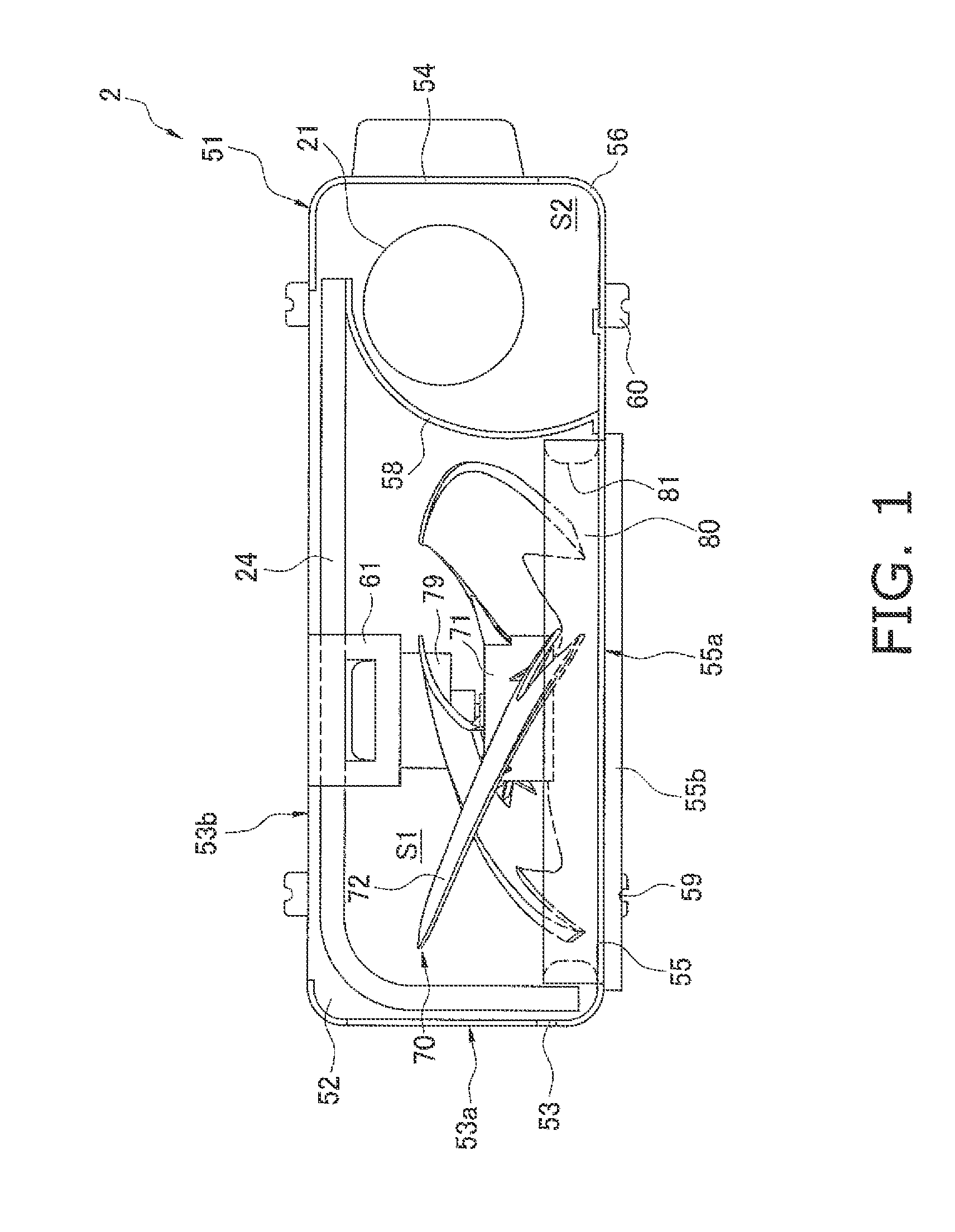

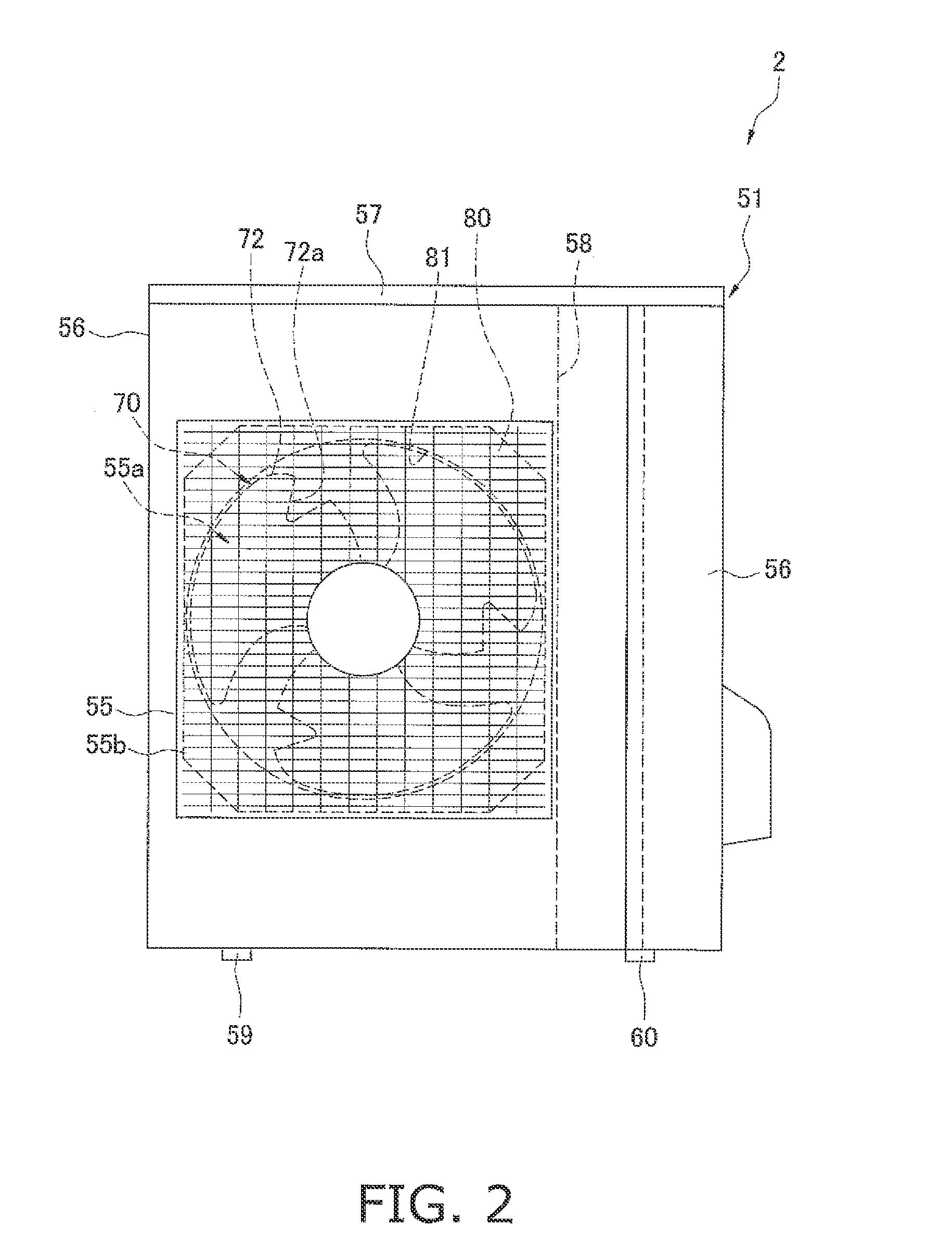

[0039](1) Overall Configuration of the Outdoor Unit

[0040]FIGS. 1 and 2 are drawings illustrating an outdoor unit 2 of an air conditioning apparatus in which is adopted an outdoor fan 70 as an axial-flow fan according to one embodiment of the present invention. Here, FIG. 1 is a plan view of the outdoor unit 2 in a condition having removed a ceiling plate 57. FIG. 2 is a front view of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com