Exhaust gas heating method

a technology of exhaust gas and heating method, which is applied in the direction of mechanical equipment, machines/engines, electric control, etc., can solve the problems of incomplete combustion of ignited fuel, achieve the effect of suppressing the generation of smoke, reducing the oxygen concentration of exhaust gas, and increasing the combustion ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

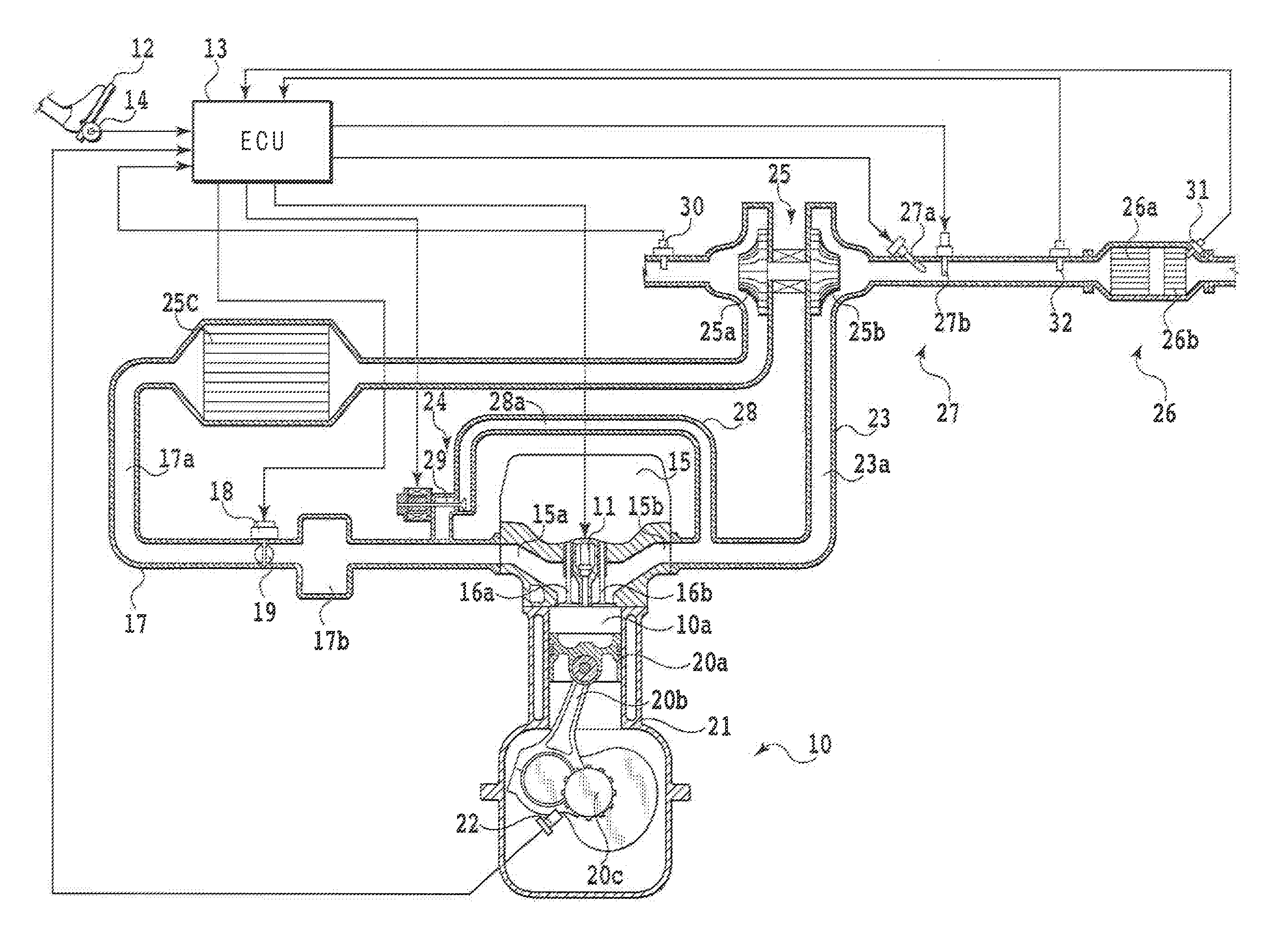

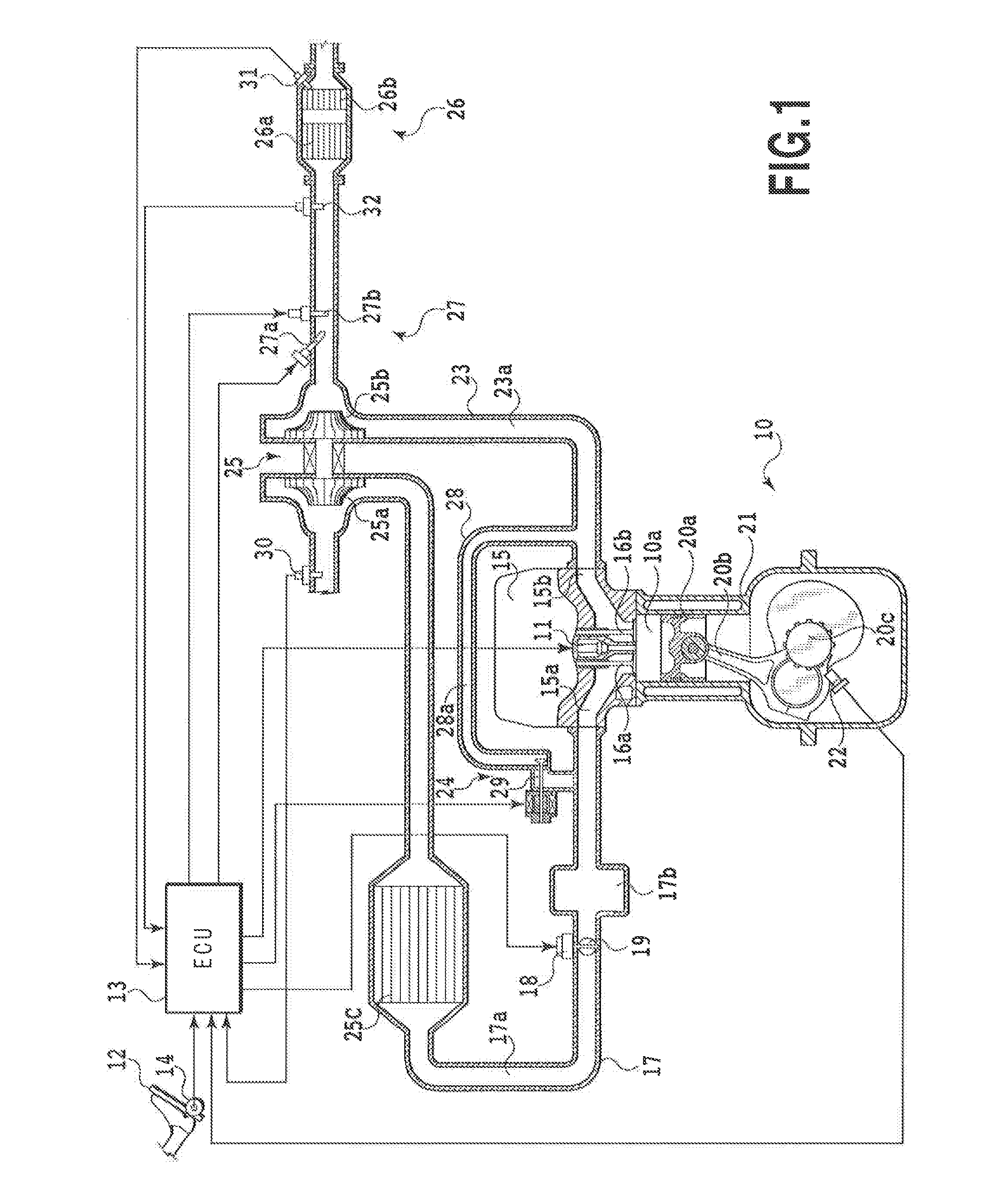

[0031]An embodiment of a compression-ignition internal combustion engine capable of implementing an exhaust gas heating method of the present invention will be described in detail with reference to FIGS. 1 to 11. Note that the present invention is not limited to this embodiment, and its configuration can be changed freely according to the specifications, characteristics, and the like required.

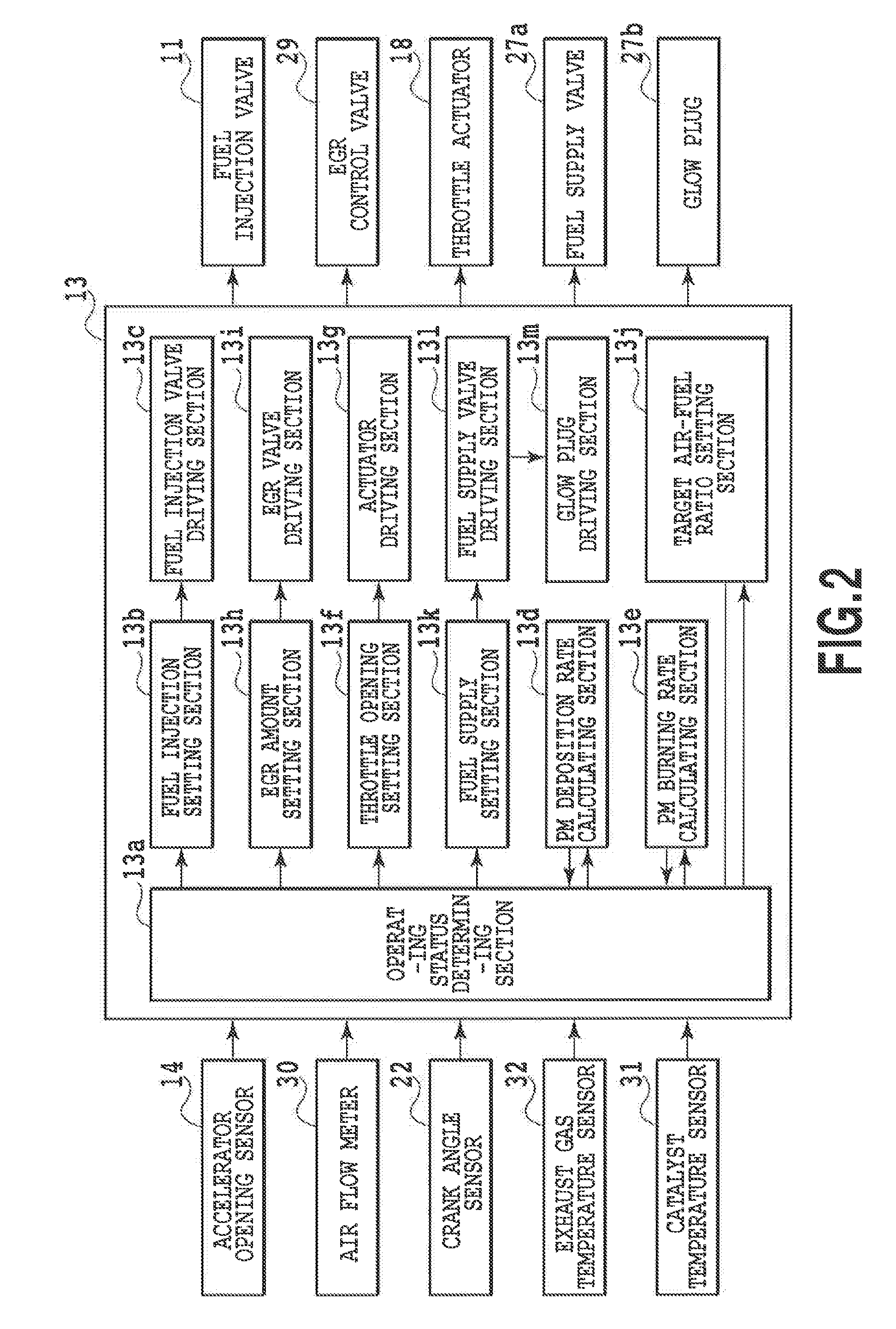

[0032]FIG. 1 schematically shows a main part of an engine system of this embodiment, and FIG. 2 shows a control block thereof. It is to be noted that a valve gear and the like for air intake and exhaust to and from an engine 10 are omitted in FIG. 1 for simplicity and convenience.

[0033]The engine 10 of this embodiment is an internal combustion engine of a compression ignition type which causes spontaneous ignition of diesel oil, serving as fuel, by injecting the diesel oil from a fuel injection valve 11 directly into a combustion chamber 10a being in a compressed state.

[0034]An ECU (Electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com