Millable Fracture Balls Composed of Metal

a technology of metal and fracture balls, which is applied in the direction of sealing/packing, other domestic objects, and well accessories, etc., can solve the problems of compromising the seating ability or the ability to float to the surface, aluminum balls b if left downhole can be particularly difficult to mill out of sliding sleeves, and long mill up times required per zon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

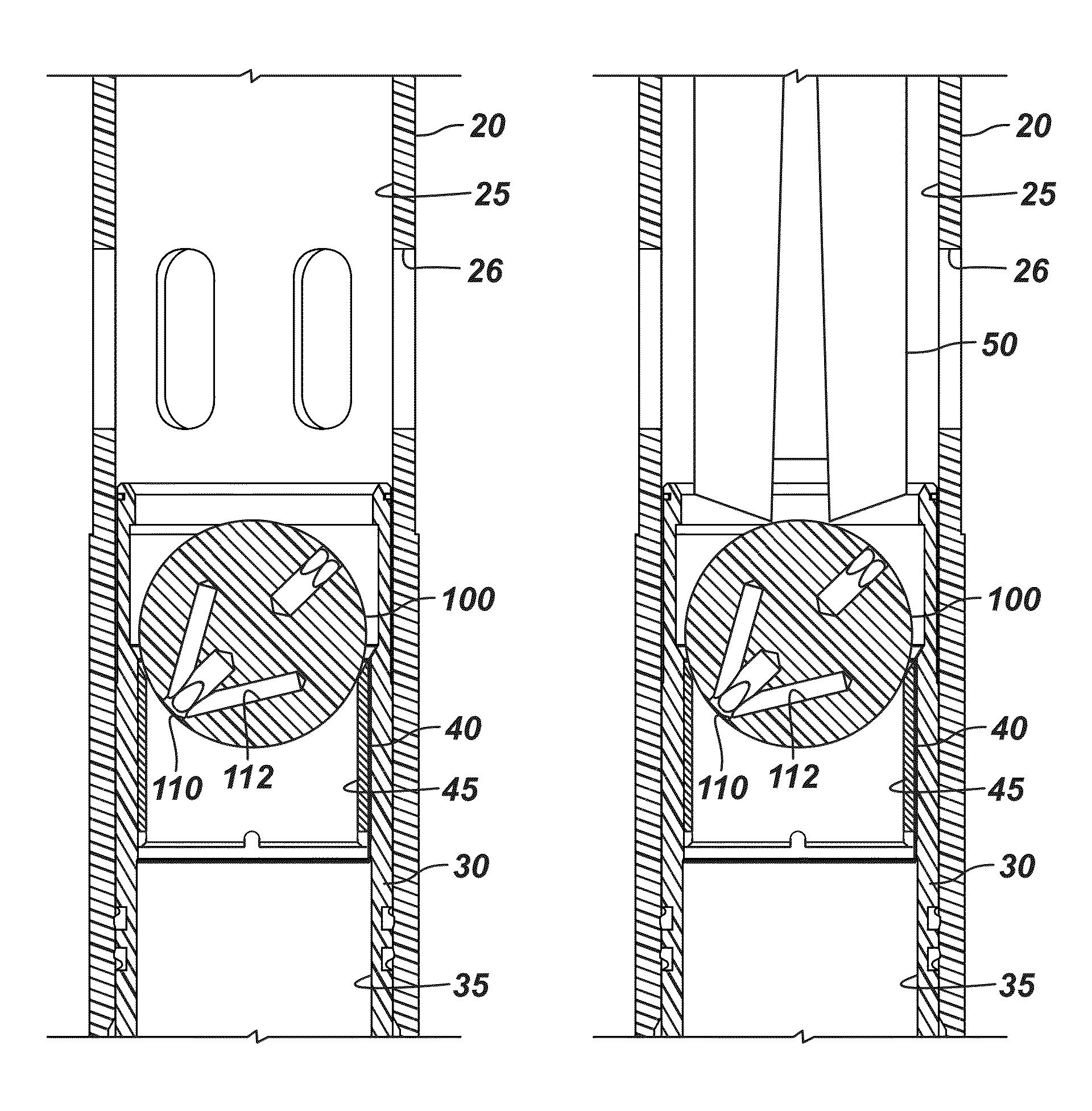

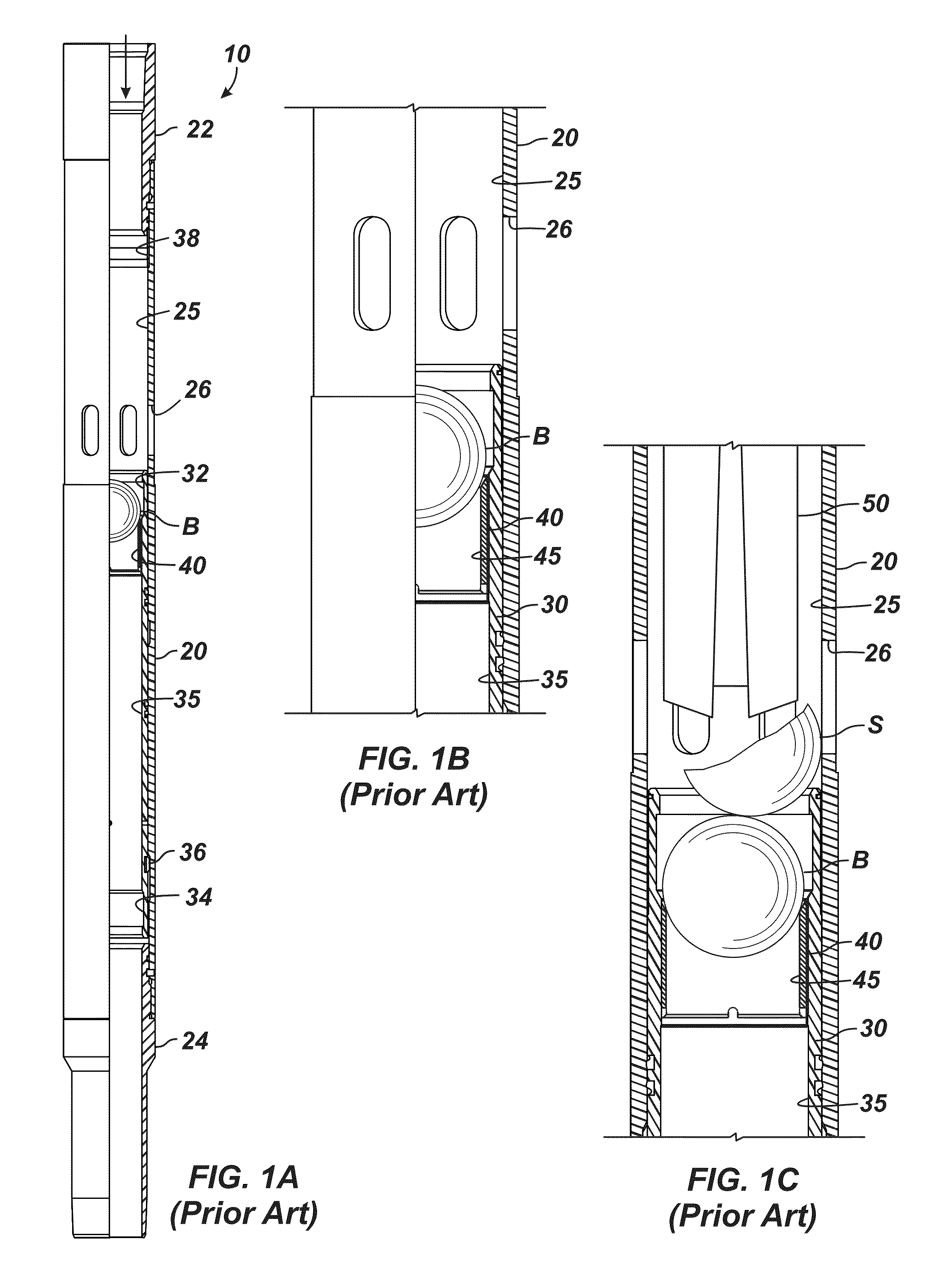

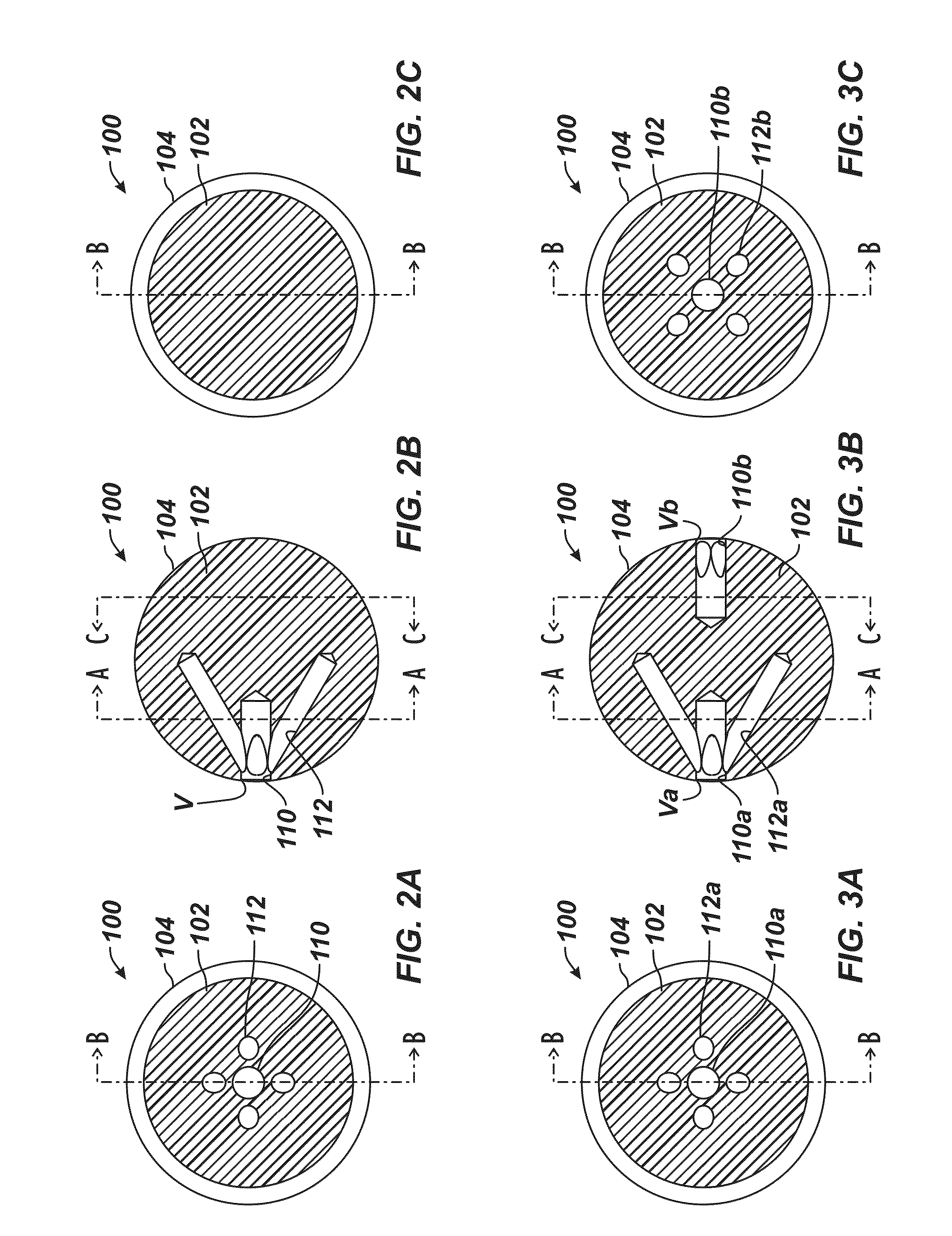

[0034]FIGS. 2A-2C illustrate cross-sectional views of a ball 100 according to the present disclosure for actuating a sliding sleeve. The ball 100 has a solid, spherical body 102 composed of a metallic material, including, but not limited to, aluminum, aluminum alloy, steel, brass, aluminum bronze, a metallic nanostructure material, cast iron, etc. The metallic material is preferably one that can be floated to the surface and can be milled if necessary. Of course, the ball 100 can be composed of any suitable material, even ceramics, plastics, composite materials, phenolics, Torlon, Peek, thermoplastics, or the like.

[0035]Voids, spaces, or holes are defined in the body 102 to facilitate milling of the ball 100 when disposed in a ball seat of a tool, such as a sliding sleeve. Because the ball 100 has the purposes of sealingly engaging the ball seat in the sliding sleeve, the ball 100 preferably is configured to maintain or produce a sufficient seal with the ball seat when seated therei...

second embodiment

[0040]FIGS. 3A-3C illustrate cross-sectional views of a ball 100 according to the present disclosure for actuating a sliding sleeve. This ball 100 is similar to that discussed previously, but tap holes 110a-b are defined in opposing sides of the ball's body 102. Each tap hole 110a-b has a plurality of angled holes 112a-b in a manner similar to that discussed previously. Preferably as shown, the angled holes 112a-b are offset from one another around the axis defined by the tap holes 110a-b so that the opposing holes 112a-b do not meet with one another inside the body 102. Because the tap holes 110a-b are offset 180-degrees on opposite sides, it is less likely that both will engage the edge of a seat when landed thereon.

[0041]As before, the tap holes 110a-b can primarily provide common vertices Va-Vb from which the opposing angled holes 112a-b can be formed so that multiple tap points do not need to be made in the ball's surface 104. The ball 100 in FIG. 3A-3C essentially defines hole...

third embodiment

[0042]FIGS. 4A-4C illustrate cross-sectional views of a metallic ball 100 according to the present disclosure for actuating a sliding sleeve. This ball 100 is similar to that discussed above with reference to FIGS. 2A-2C in that a tap hole 110 and angled holes 114 are defined in one side of the ball 100. Rather than having four angled holes as in the previous embodiment, this ball 100 has three angled holes 114 drilled at about every 120-degrees around the tap hole 110.

[0043]In other differences illustrated, the angled holes 112 can be drilled at a shallower angle from the tap hole 110. Additionally, the ends of the angled holes 112 can extend beyond the midpoint of the ball's body 102. Thus, the angled holes 112 extend nearly to the opposing side of the ball's body 102.

PUM

| Property | Measurement | Unit |

|---|---|---|

| metallic | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| sealing area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com