Cold and hot pack capable of being plasticized

a cold and hot pack technology, applied in the field of cold and hot packs, can solve the problems of inability to match the shape of human body, inability to cause unstable motion such as floating, poor performance, etc., and achieve the effect of preventing sag, preventing sag, and easily controlling the volume of fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

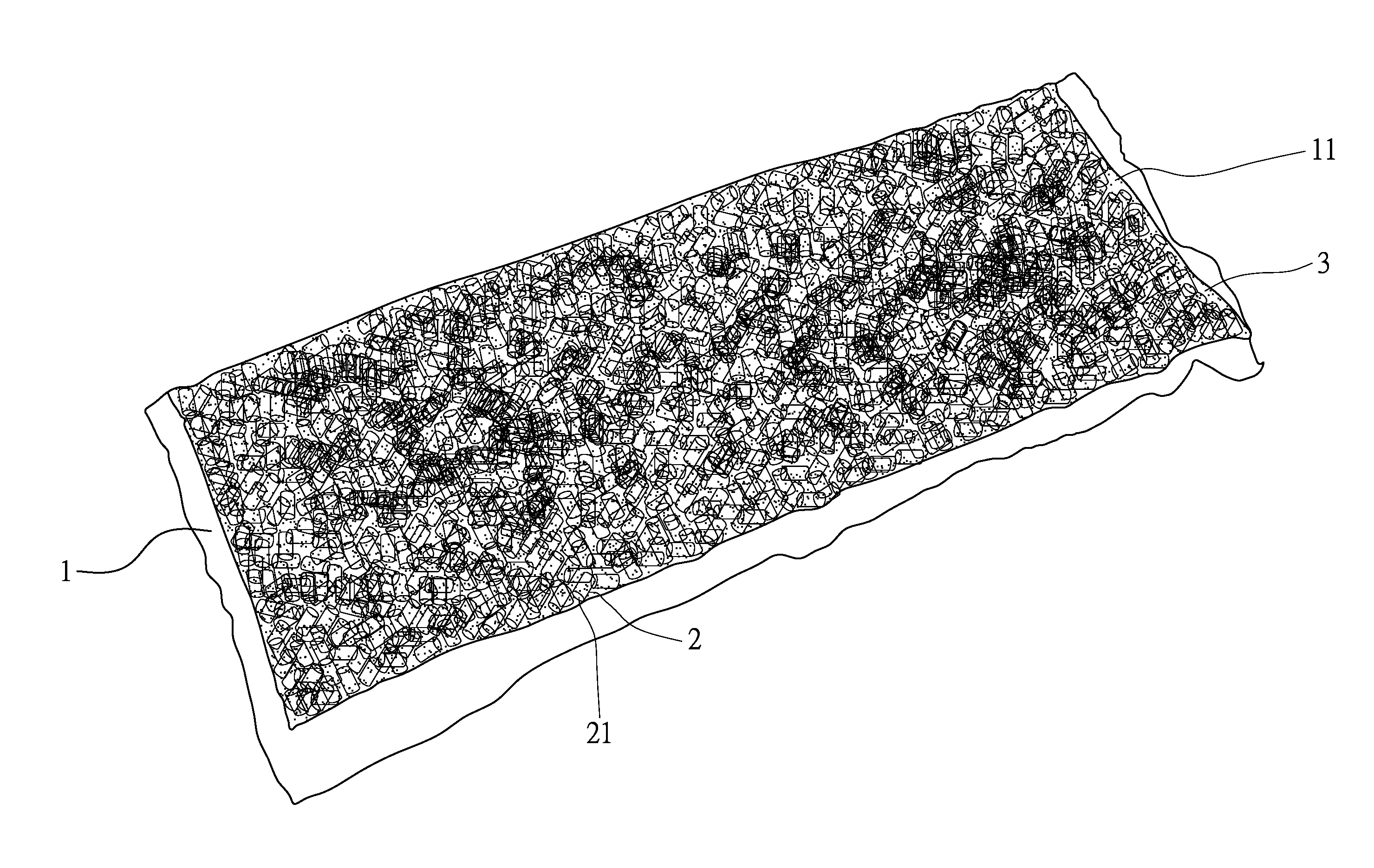

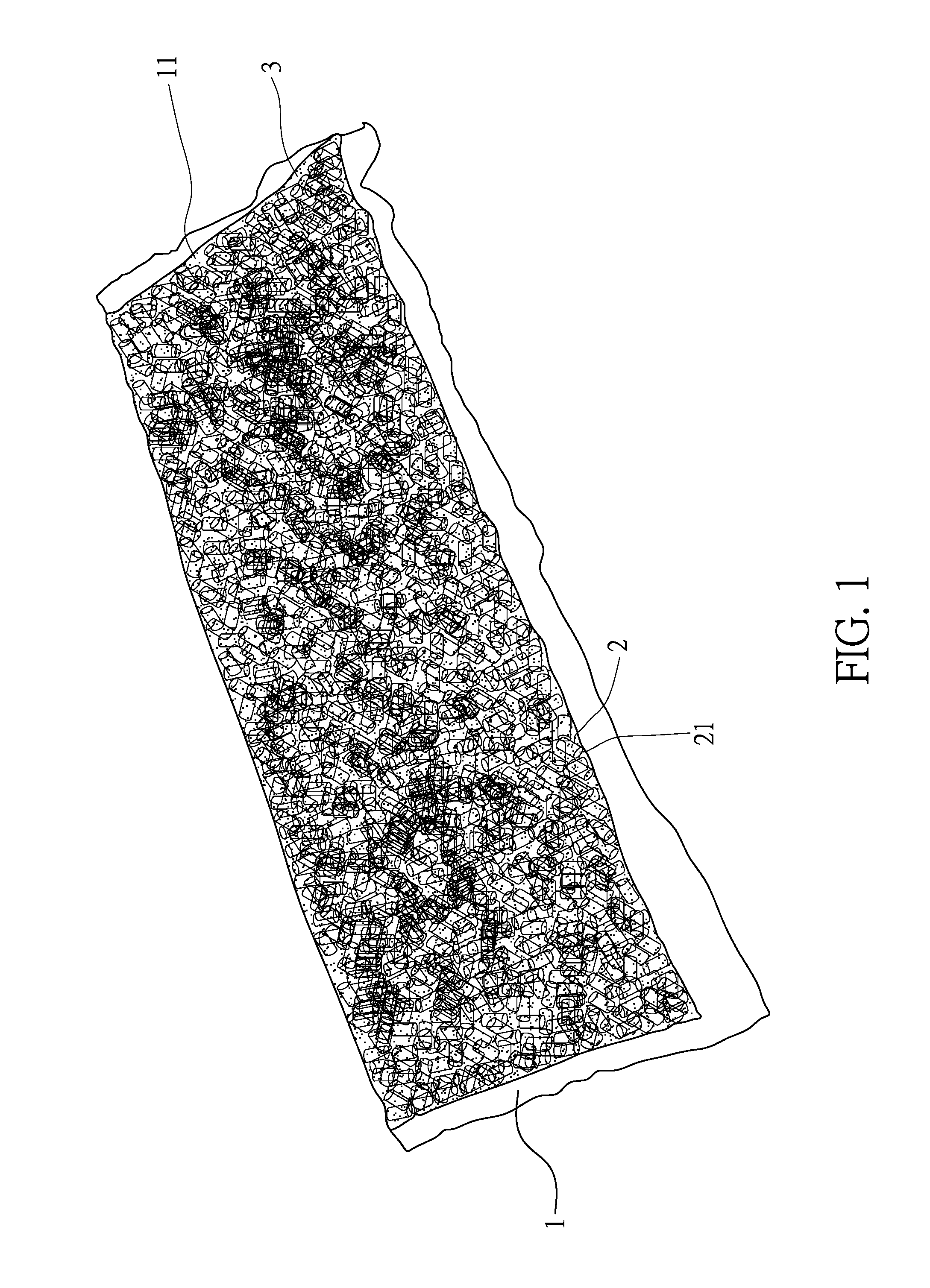

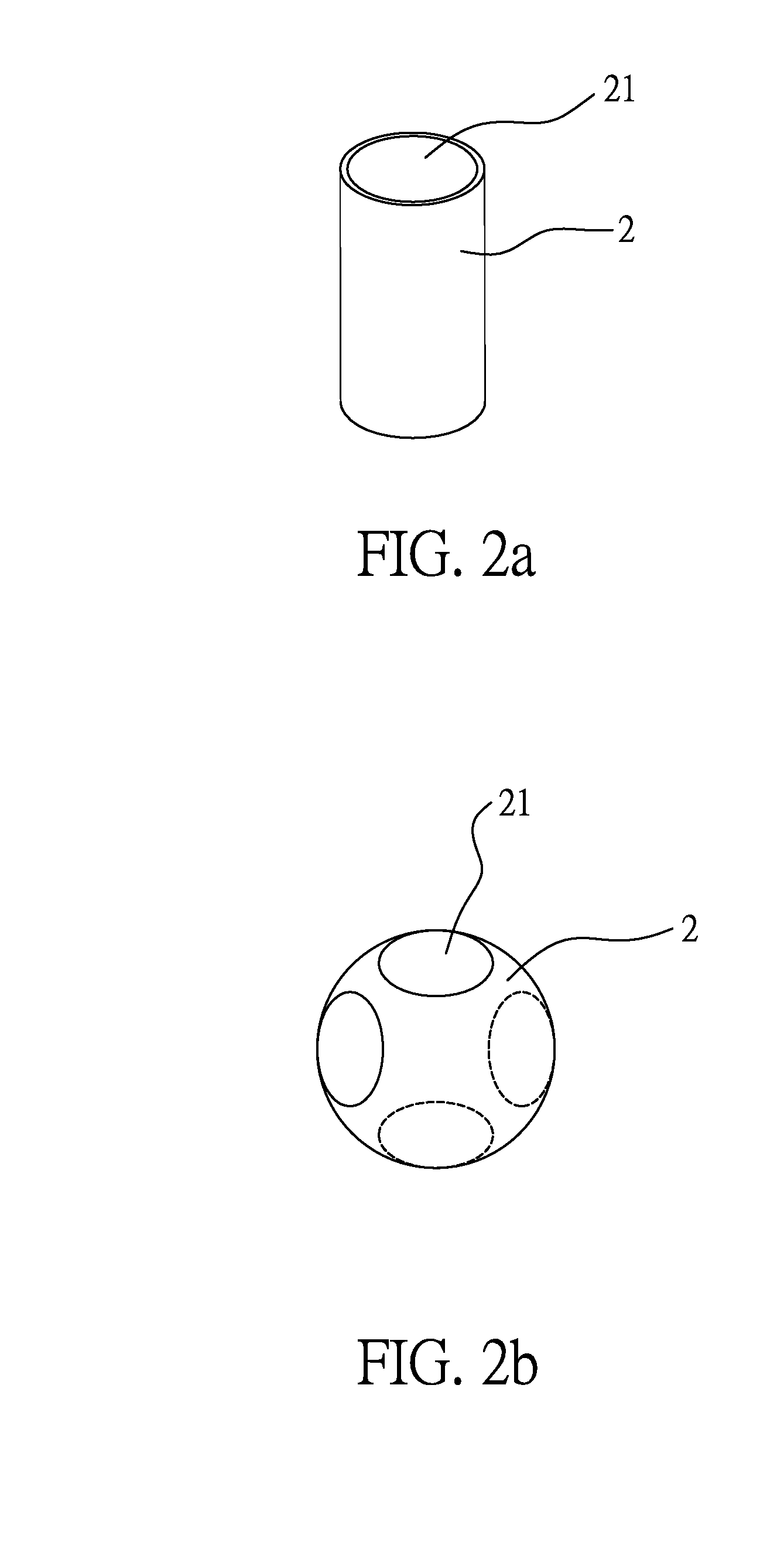

[0031]Referring from FIG. 1 to FIG. 4, the cold and hot pack provided by the present invention comprises a bag member 1, plural particle-like supporters 2 and a fluid 3.

[0032]As shown in FIG. 1, the bag member 1 is made of an impermeable soft material, e.g. but not limited to a high polymer selected from polyvinylchloride (PVC), Polyurethane (PU), PE / Nylon, ethylene vinyl acetate (EVA), styrene ethylene butylene styrene (SEBS) and silicon, and a surface of the above-mentioned high polymer can be provided with a fabric thereby allowing the bag member 1 to be formed with a prettified outlook and higher quality.

[0033]Wherein, the dimension of the bag member 1 is greater than the total volume defined by the particle-like supporters 2 and the fluid 3, thereby allowing the supporters 2 and the fluid 3 to be accommodated in an inner space formed inside the bag member 1. As shown in FIG. 1, after the plural particle-like supporters 2 and a certain amount of the fluid 3 are accommodated in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com