Medium separating and supplying mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

1. First Exemplary Embodiment

[1-1. Configuration of Medium Separating and Supplying Mechanism]

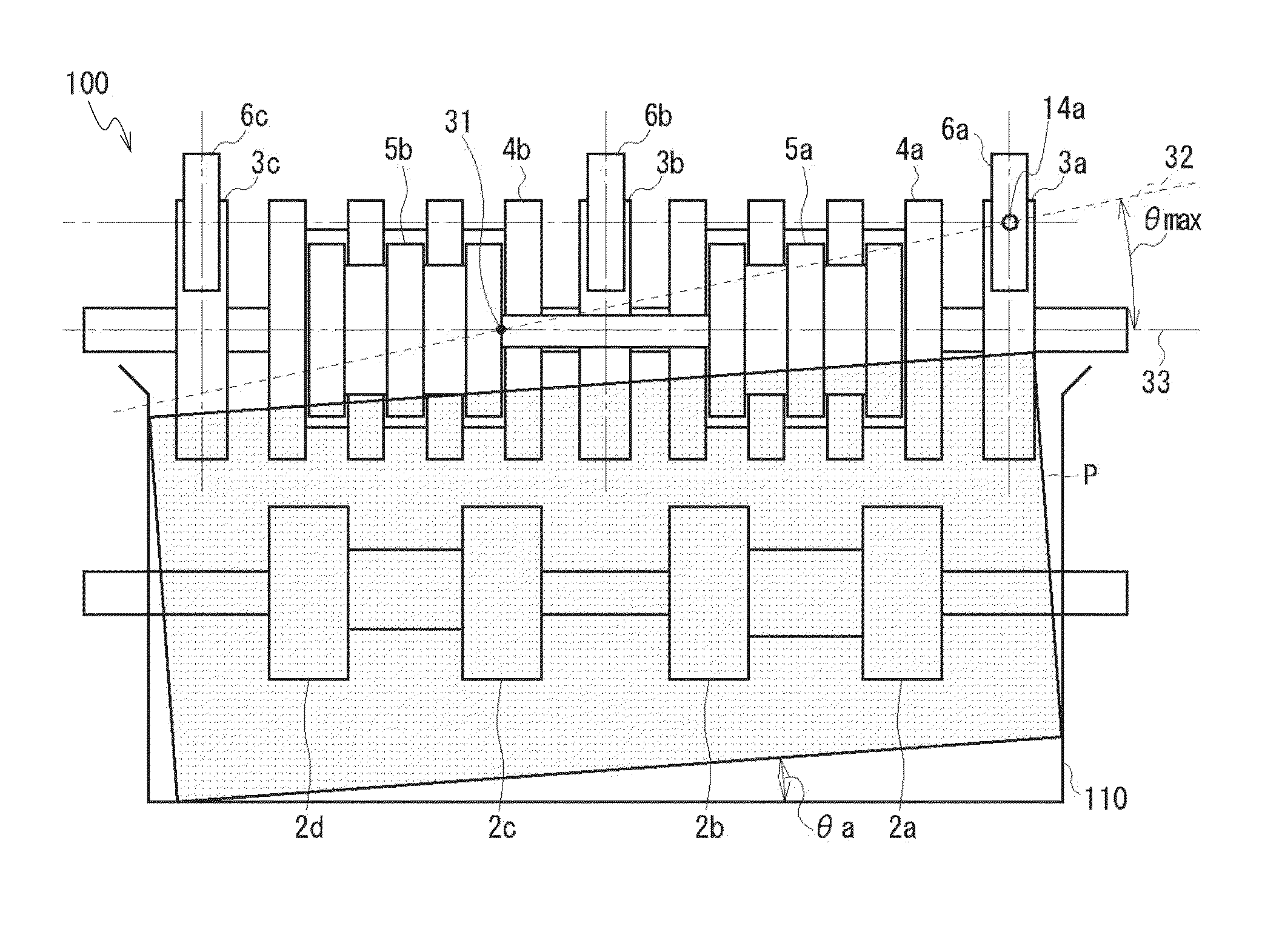

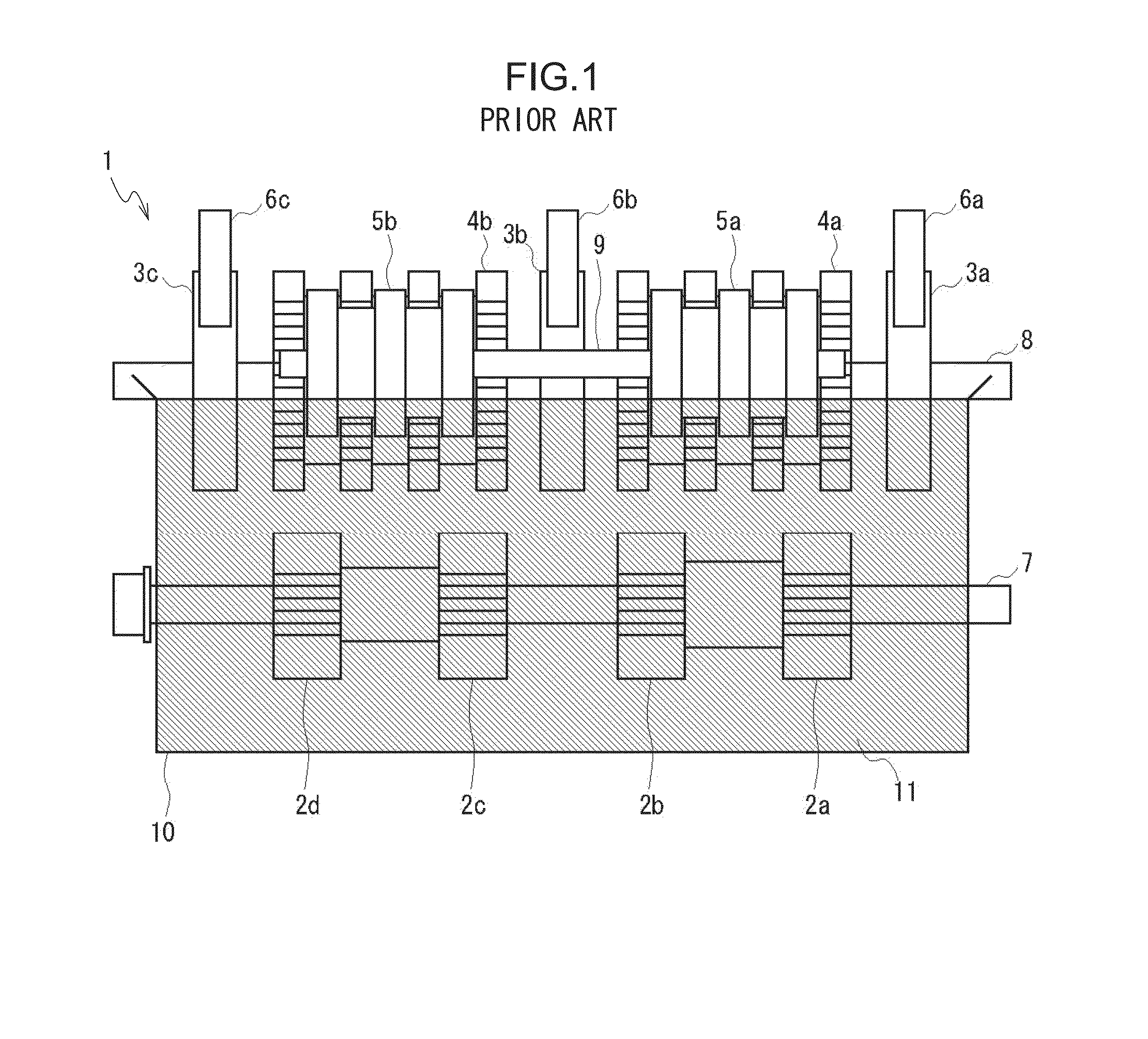

[0087]First, a first exemplary embodiment will be described. FIG. 19A shows the conventional medium separating and supplying mechanism 1, and FIG. 19B shows a medium separating and supplying mechanism 100 in the first exemplary embodiment. The medium separating and supplying mechanism 100 has the same configuration as that of the conventional medium separating and supplying mechanism 10 except that the side surface guide 10 is replaced with a side surface guide 110.

[0088]The side surface guide 110 has a supply direction length L11 and a width direction length W11 that are shorter than a supply direction length L1 and a width direction length W1 of the side surface guide 10.

[0089]Specifically, the supply direction length L11 and the width direction length W11 of the side surface guide 110 are determined in the following way.

[0090]As shown in FIG. 20, PW, PH, and PD denote a supply direction ...

second exemplary embodiment

2. Second Exemplary Embodiment

[2-1. Configuration of Medium Separating and Supplying Mechanism]

[0126]Next, a second exemplary embodiment will be described. (1) of FIG. 29 shows the conventional medium separating and supplying mechanism 1, and (2) of FIG. 29 shows a medium separating and supplying mechanism 200 in a second exemplary embodiment. In FIGS. 1) of 29 and (2) of 29, the side surface guide 10 is omitted for convenience of description. Further, in the medium separating and supplying mechanism 200 of the second exemplary embodiment, the side surface guide 110 of the first exemplary embodiment may also be used instead of the side surface guide 10.

[0127]The medium separating and supplying mechanism 200 has a configuration where, compared to the conventional medium separating and supplying mechanism 1, a supply feed roller 203a and supply roller 206a and a supply feed roller 203c and supply roller 206c are each nearer to the center by a distance D1. Other configurations are the ...

third exemplary embodiment

3. Third Exemplary Embodiment

[3-1. Configuration of Medium Separating and Supplying Mechanism]

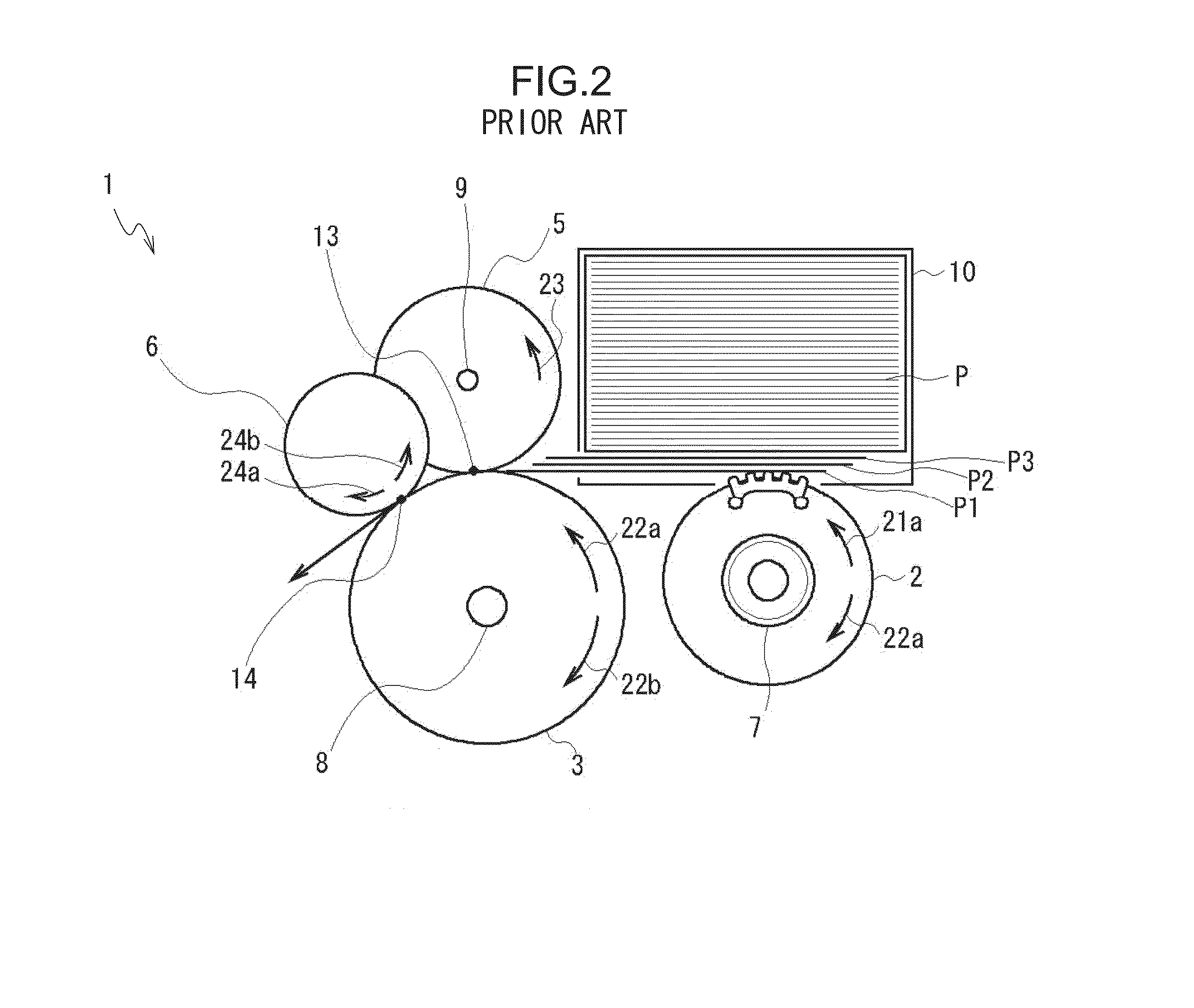

[0138]Next, a third exemplary embodiment will be described. As shown in FIG. 31 and FIG. 32, a medium separating and supplying mechanism 300 in the third exemplary embodiment is given a configuration including pickup rollers 302, supply feed rollers 303, separation feed rollers 304, separation gate rollers 305, supply rollers 306, shafts 307, 308, and 309, and the side surface guide 10.

[0139]In FIG. 32, the side surface guide 10 is omitted for convenience of description. Further, in the medium separating and supplying mechanism 300 of the third exemplary embodiment, the side surface guide 110 in the first exemplary embodiment may also be used instead of the side surface guide 10.

[0140]The pickup rollers 302 are arranged on and fixed to the shaft 307 in a line in the width direction below the stacking area 11 of the side surface guide 10. The shaft 307 is rotatably supported by bearings and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com