Leave-in-Place Concrete Formwork Combining Plate Dowels, Divider Plates, and/or Finishing, Armoring and/or Sealing Molding

a technology of concrete formwork and divider plates, applied in the field of concrete flatwork, can solve the problems of inability to provide positive load transfer between adjacent panels, and inability to create cracks in contraction joints, etc., and achieve the effect of simplifying the use of contractors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

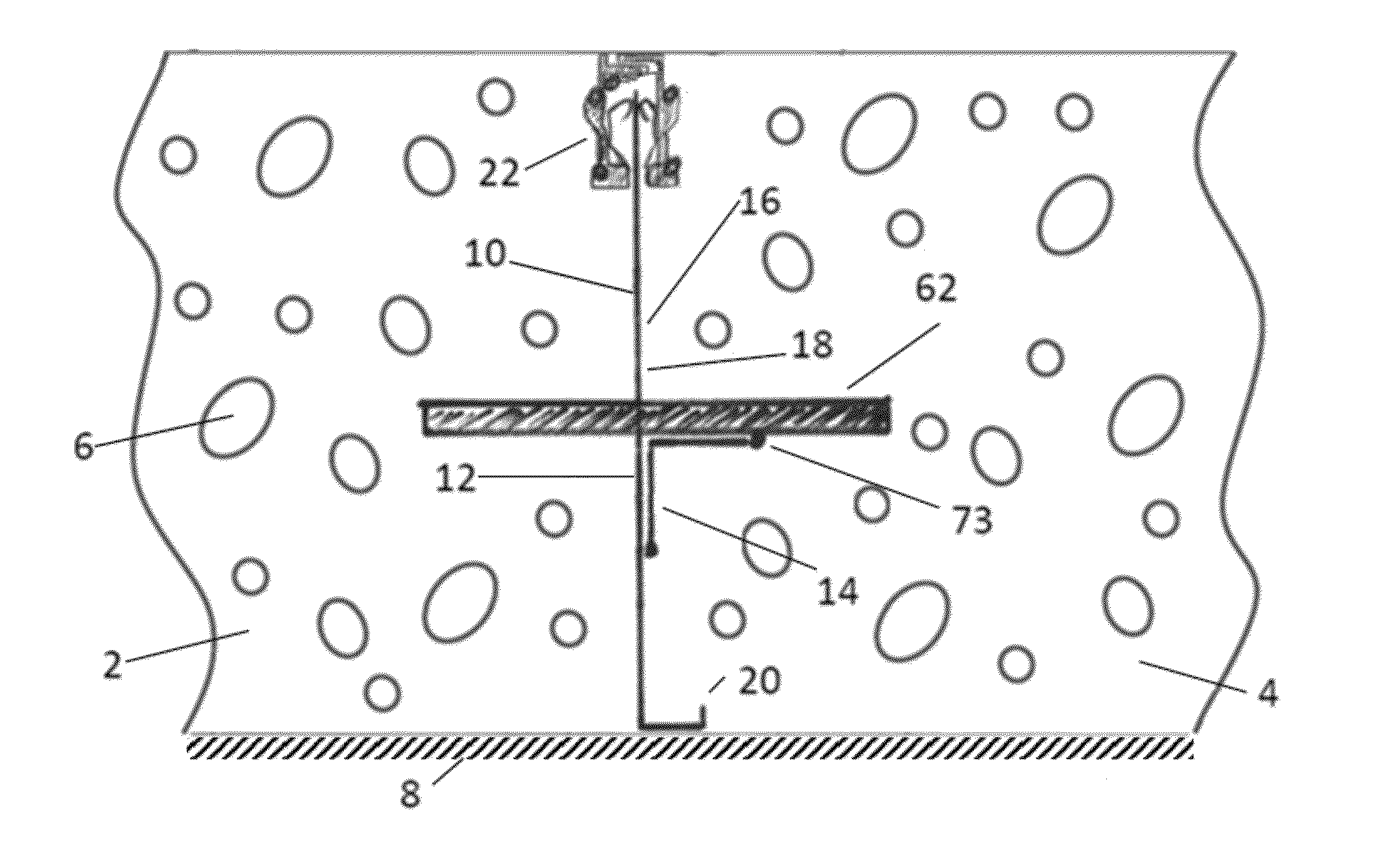

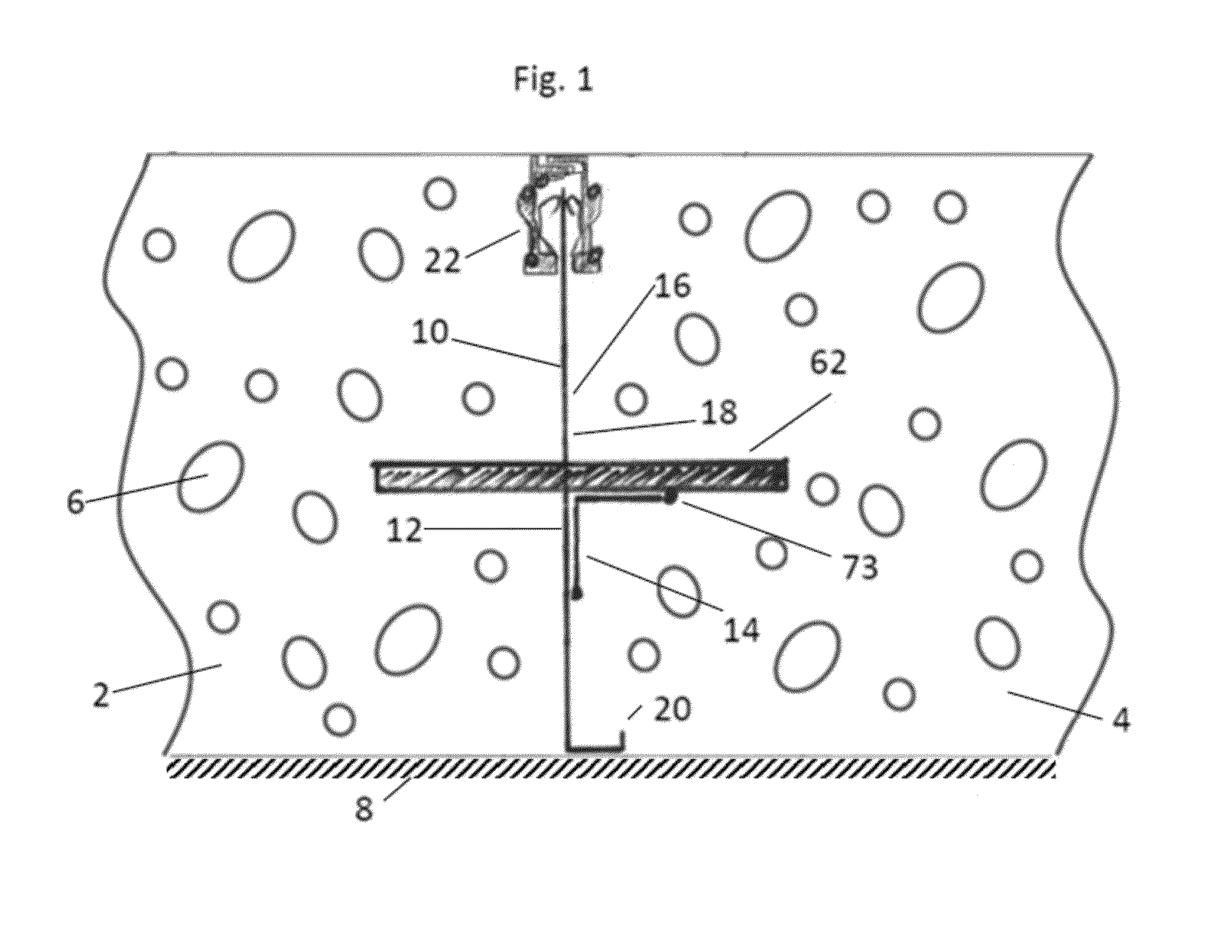

[0011]As in FIG. 1, two slabs of concrete 2 and 4 are seen in cross-section when cut open or seen from their outer edges. The concrete has the usual construction of binder and inclusions such as aggregate 6. The slabs 2, 4 rest on a typical subgrade or base material 8.

[0012]A divider plate 10 defines the upright edges 12, 14 of the slabs 2, 4 at a joint 16 where the slabs are adjacent each other. They “meet” at the joint 16 in the sense that they terminate at the joint 16. They are also “separated” at the joint 16 in the sense that the divider plate 10 lies between them. They also further separate if the joint 16 between them is a construction and / or contraction joint and they move back from each other, under the action of concrete shrinkage or otherwise.

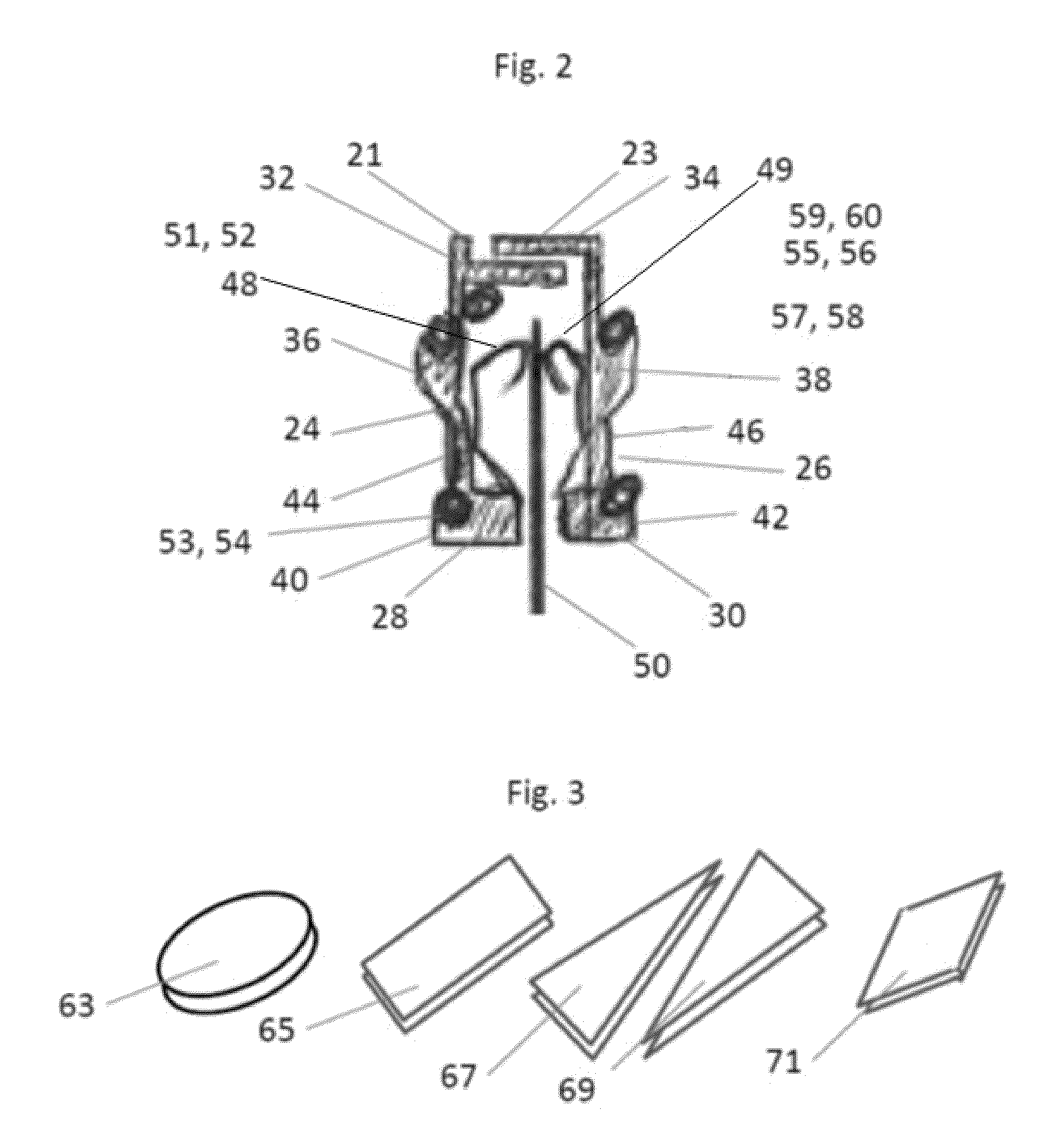

[0013]The divider plate 10 includes a vertically oriented extension 18, which extends from the subgrade or base 8 to the top of the slabs 2, 4. The extension 18 may have this extent by reason of incorporating a setting bracket 20 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com