Paper bag with integrated handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

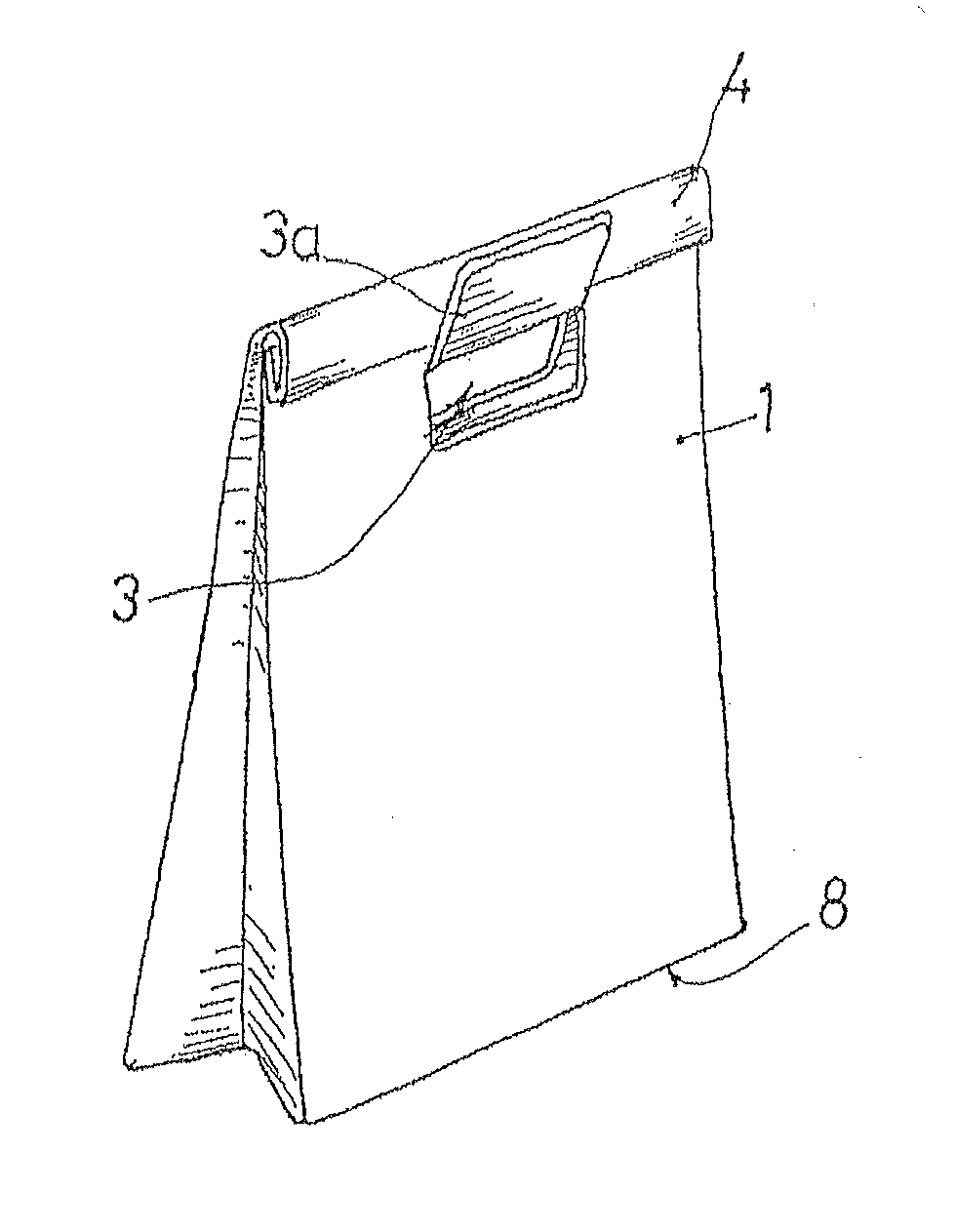

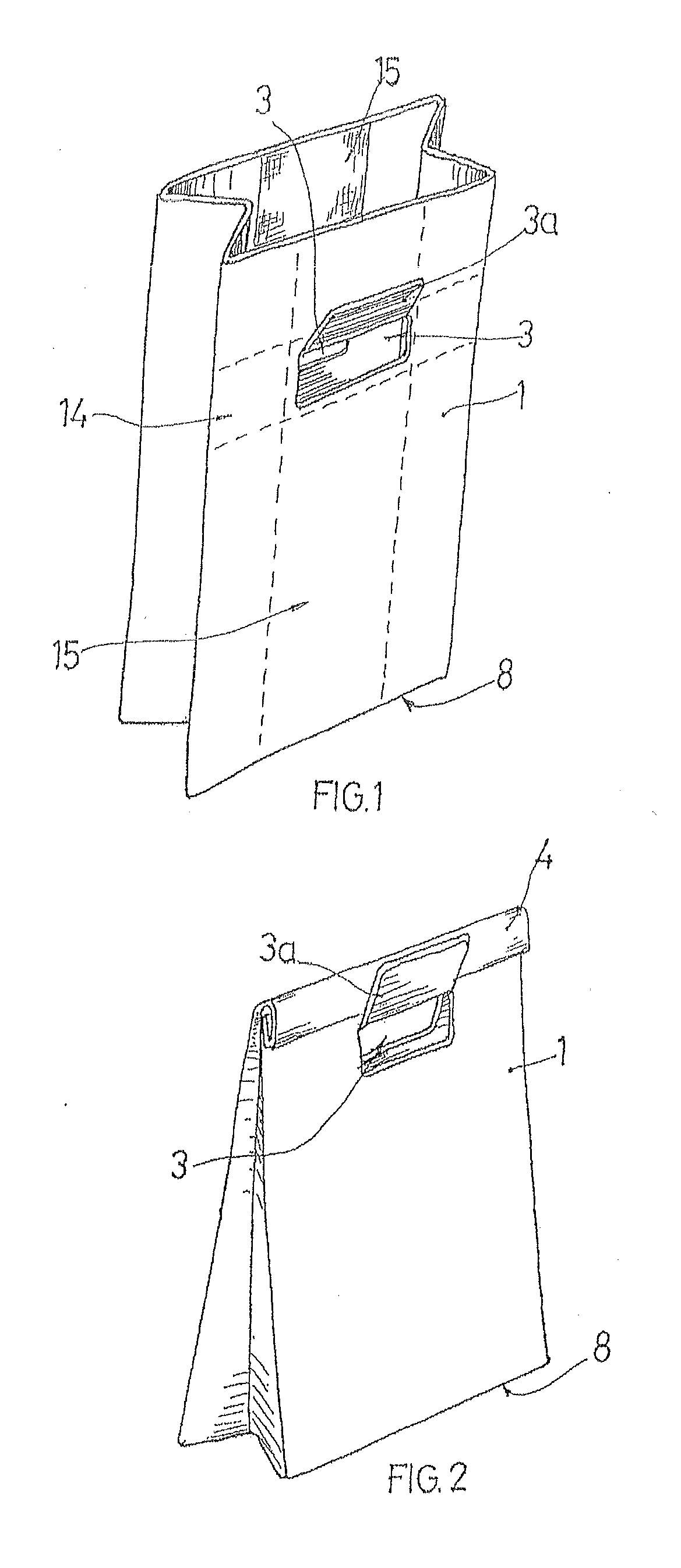

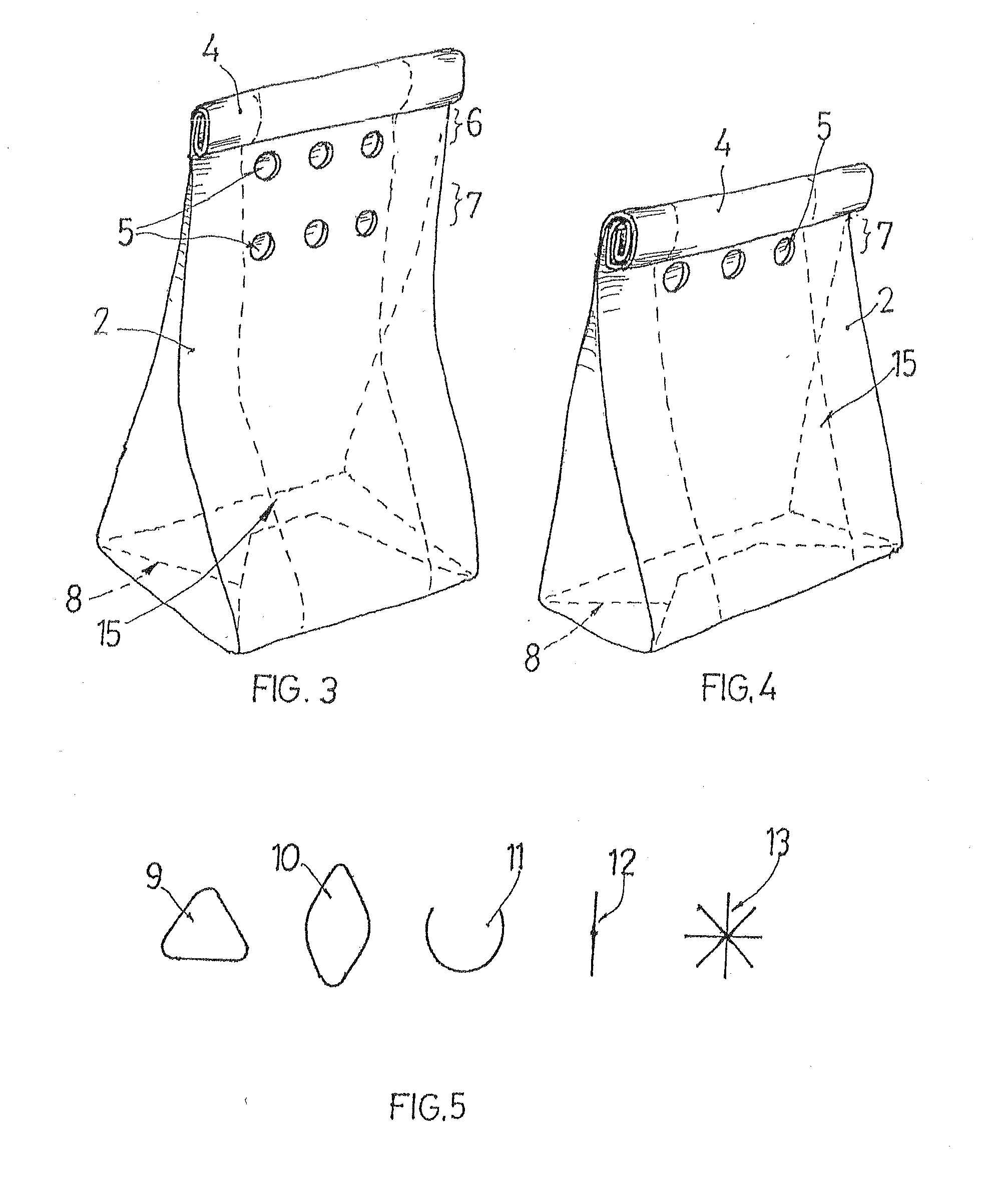

[0018]According to the referenced drawings, the paper bag is manufactured like the well known “pleated”-style (1) or “American”-style (2) without said pleat.

[0019]According to the embodiment represented in FIGS. 1 and 2, the “pleated”-style bag (1) is provided, in this embodiment, with a rectangular die cut drill hole (3) located near the top edge of the bag and centered with respect to the side edges of the bag. This die cut drill hole (3) which still has the flap (3a) after the die cut, is located at a sufficient distance from the top edge which allows performing some folds (4) to close the bag (1) at the top part, the die cut drill hole (3) remaining just below the aforementioned folds (4) which, in turn, work as a reinforcement for the handle.

[0020]The bag can also be manufactured, in the embodiment represented in FIGS. 3 and 4, according to the “American”-style (2), provided with two die cut drill holes areas, in this case several die cut drill holes with a circular shape (5), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com