Mount for a boat propulsion unit

a technology for propulsion units and boats, applied in the direction of waterborne vessels, propeller elements, vessel construction, etc., can solve the problems of rigid mounting, noise, vibration, rigid mounting,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

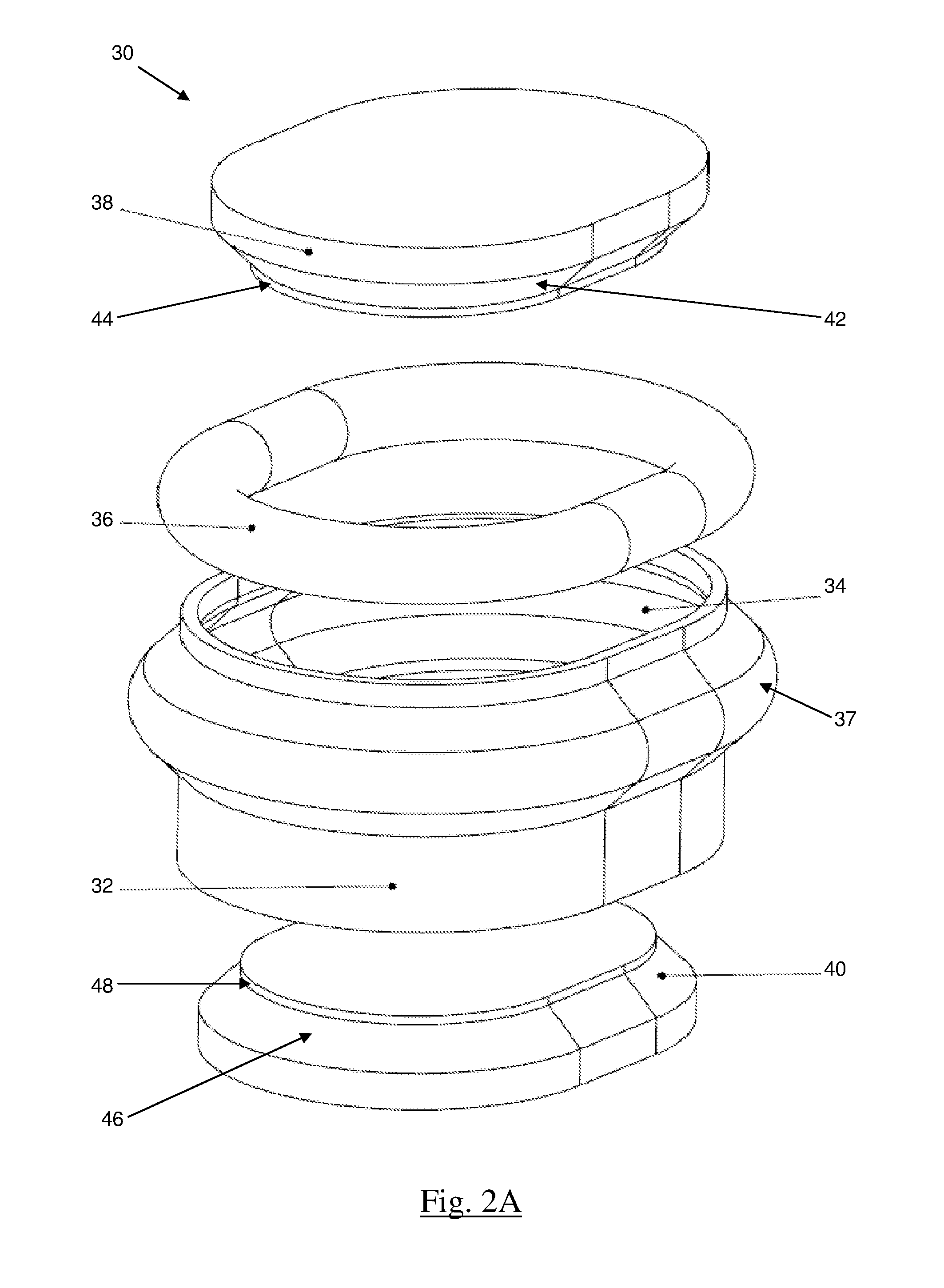

[0045]With reference to FIG. 2A, there is illustrated a mount 30 for a boat propulsion unit (not shown) according to the present invention. The mount 30 comprises a hollow generally cylindrical collar 32 (also known as a motor bed). In this embodiment, the collar 32 is designed to be integrally moulded within a hole in the bottom of a boat's hull (not shown). The collar 32 includes an inner annular groove 34 configured to partly receive an annular rubber gasket in the form of O-ring 36. In this particular embodiment, the collar 32 also includes an annular bulge 37 on its external surface, to accommodate the inner annular groove 34.

[0046]It will be noted from FIG. 2A that the mount 30 has a generally obround shape when viewed from above. As stated previously, this shape is advantageous in handling the forwards and backwards forces applied to the mount 30 when in use.

[0047]The mount 30 further comprises an upper part 38 configured for attachment to an inboard motor or its housing (not...

second embodiment

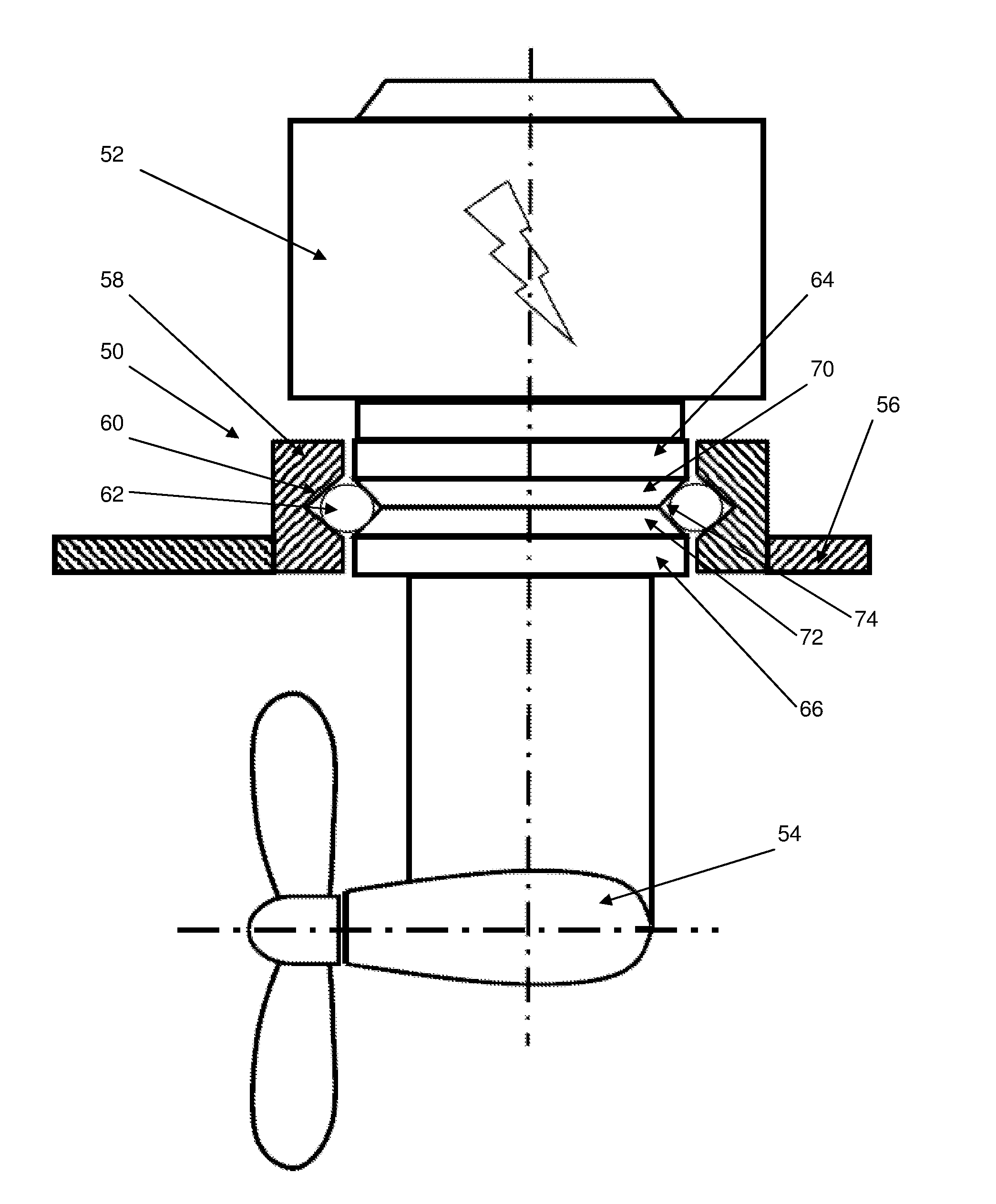

[0052]FIG. 2B shows a part cross-sectional view of an assembled mount 50, similar to that shown in FIG. 2A, when attached to a propulsion unit comprising an inboard motor 52 and saildrive 54 of a boat 56, according to the present invention. The mount 50 comprises a hollow obround cylindrical collar 58 affixed within a hole in the bottom of the boat's hull 56. The collar 58 includes an inner annular V-shaped groove 60 configured to partly receive an annular rubber gasket in the form of O-ring 62.

[0053]As above, the mount 50 further comprises an upper part 64 which, in this case, is attached to the inboard motor 52 and a lower part 66 which, in this case, is attached to the saildrive 54. Also as described above, the upper part 64 and the lower part 66 will be hollow in practice to allow a motor drive shaft (not shown) to extend through the mount 50 to operate the saildrive 54 and the upper and lower parts 64, 66 also include an attachment mechanism (not shown) which is described below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com