Dual flush toilet devices

a technology of toilets and toilets, applied in the direction of valves, mechanical devices, transportation and packaging, etc., can solve the problems of premature closing of flapper valves, etc., and achieve the effect of less water and more water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

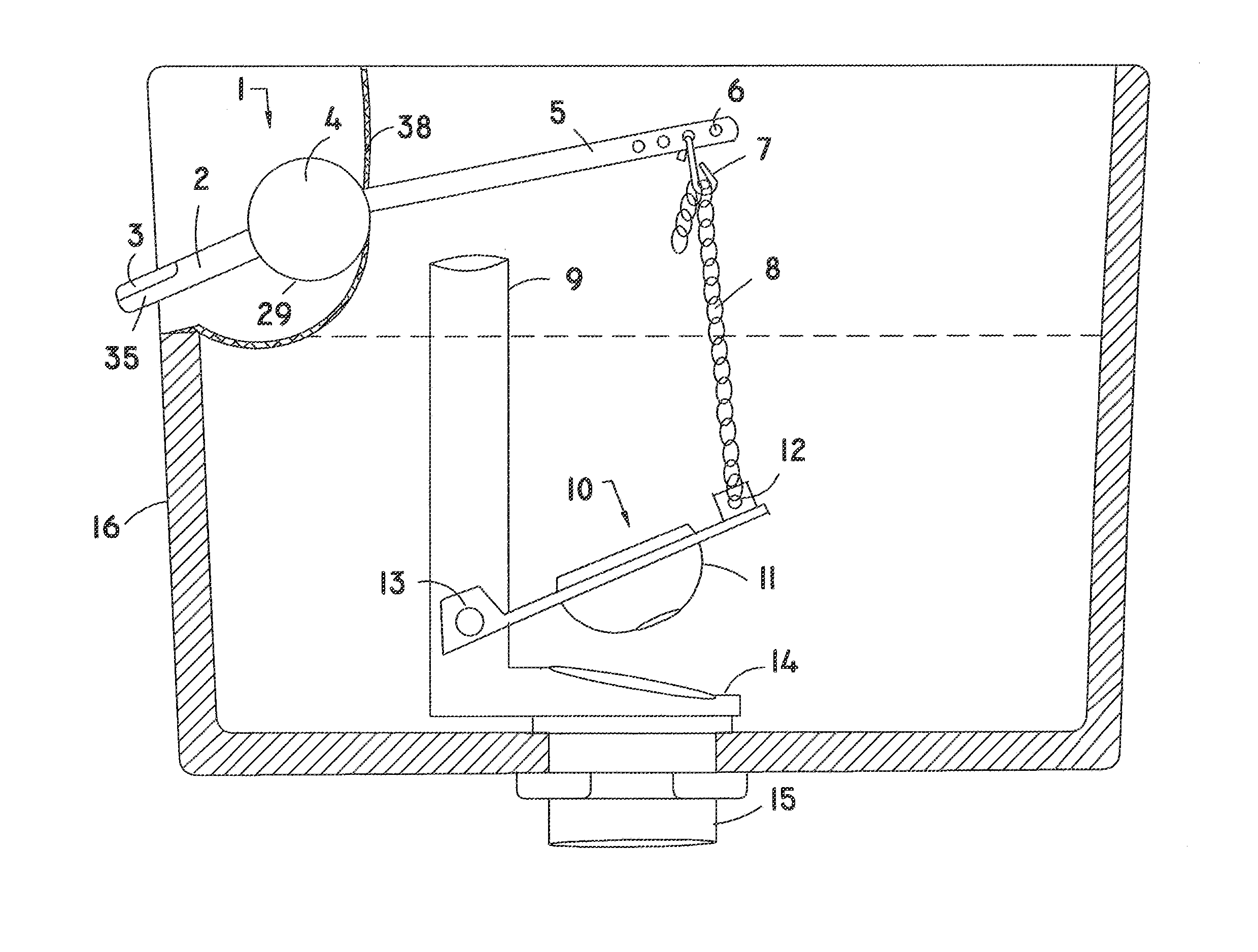

[0050]The present invention provides a dual flush device 1 and a float assembly 73 or 76 for use in a toilet tank 16.

[0051]In FIG. 1, an embodiment of dual flush device 1 of the present invention has been installed in a toilet tank 16 through a built-in hole 29 on the front wall of tank 16 behind a flush handle knob 4. It replaces the original flush lever assembly to retrofit a conventional single flush toilet to a dual flush toilet. The dual flush device 1 is shown in an activated position when a first flush handle 2 is depressed to lift flush lever 5 and open a flapper flush valve 10. Inside toilet tank 16, there are flapper valve 10, which is connected at an eyelet 12 by a chain 8 to flush lever 5 of dual flush device 1 and is pivotally mounted on two opposite projections 13 on an overflow tube 9, and an inclined flush valve seat 14 to mate with flapper valve 10. Connected to valve seat 14 is a discharge pipe 15 into which the tank water is drained into a toilet bowl (not shown)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com