Rimless toilet

a rimless, toilet technology, applied in water installations, construction, domestic applications, etc., can solve the problems of reducing the area available to accept urine streams, difficult to get good cleaning action under the rim, and potentially harmful materials that can remain under the rim for extended periods of tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

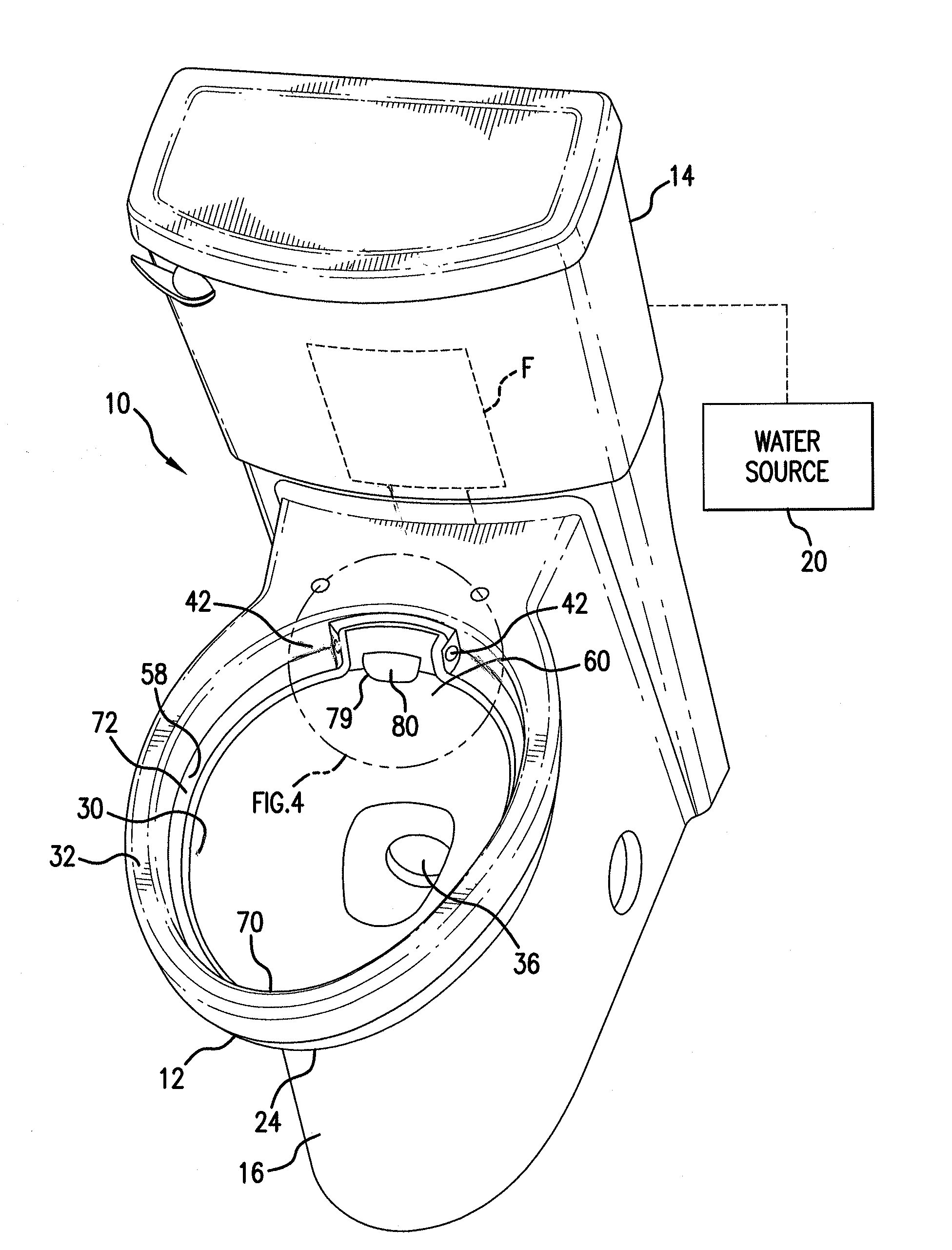

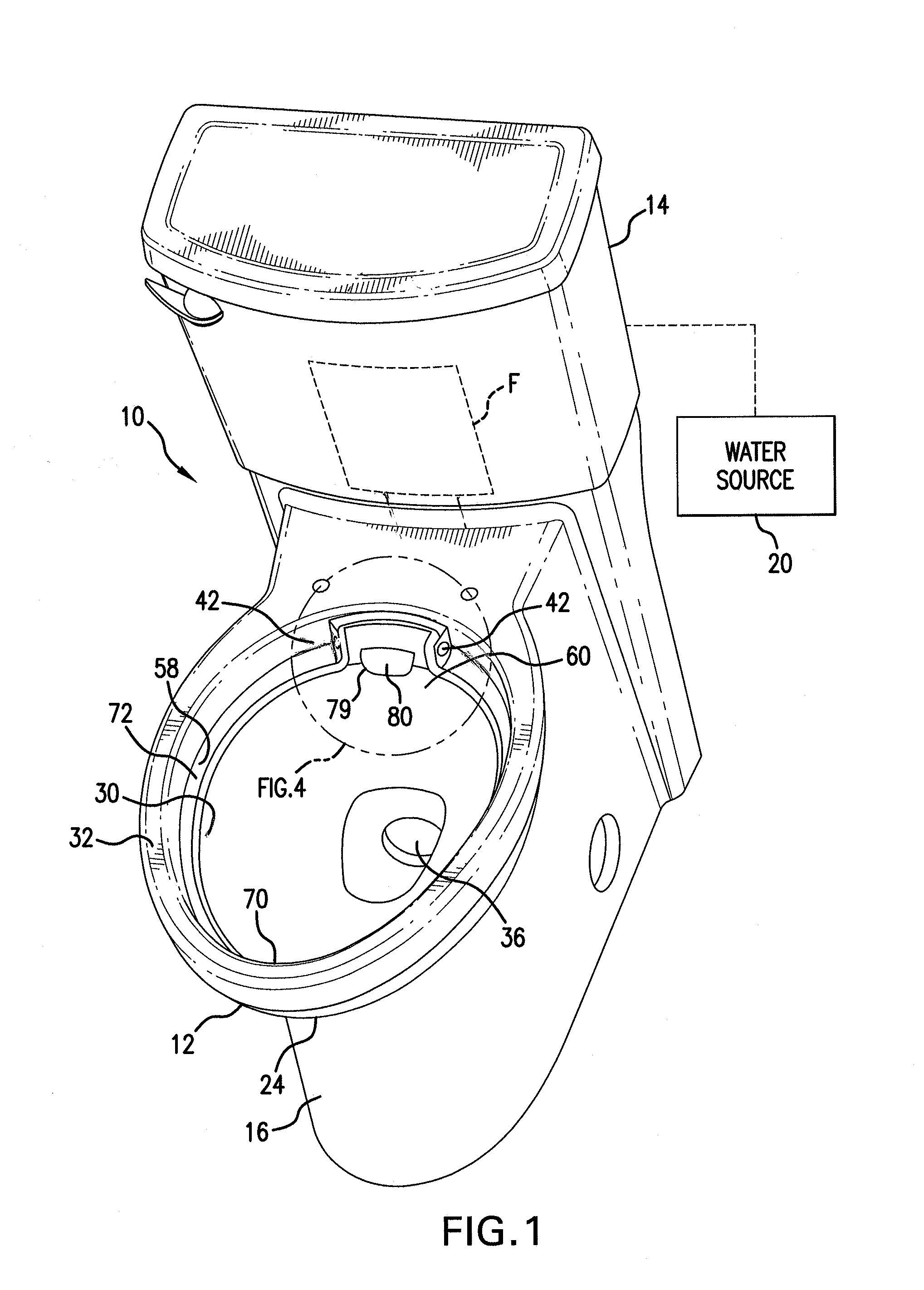

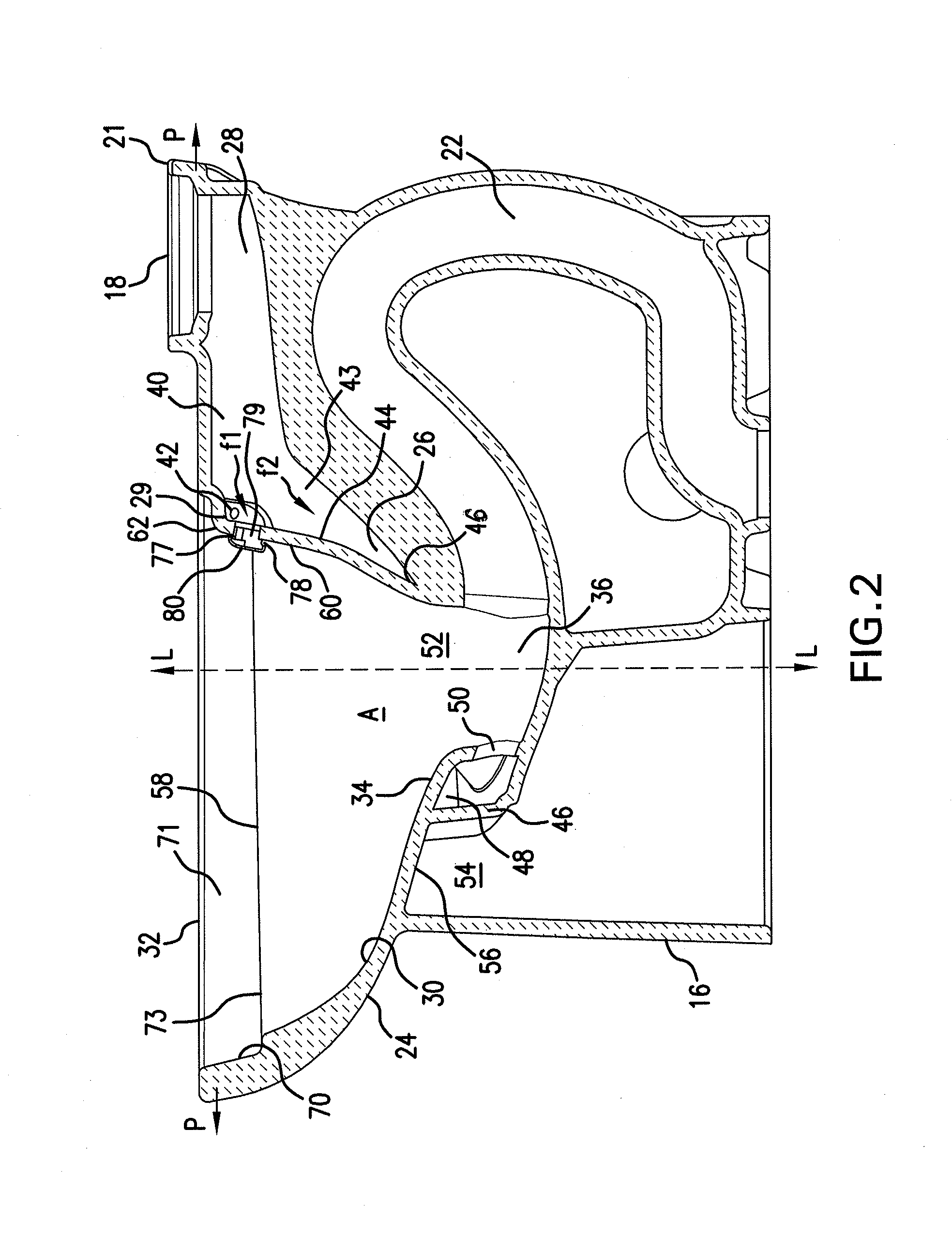

[0071]The rimless toilet described herein is designed to be able to incorporate advantages achieved in flush efficiency from use of a jetted toilet flush system as well as the advantages of bowl cleanliness and an enlarged interior bowl pan or target area associated with the rimless design configuration. The toilet is able to provide strong flushing and cleaning capability without use of a rim channel wash function and without pressurization of rim water as in traditional prior art jetted toilet bowls.

[0072]The toilet is able to provide good flush capability consistent with today's 6.0 liters / flush (1.6 gallons / flush toilets), and preferably with toilets utilizing 4.8 liters / flush (1.28 gallons / flush), while allowing for a clean bowl after flushing and without the deposition of dirt and germs that can occur in conventional toilets having an overhanging rim channel. The balance in achieving excellent bowl cleanliness in a jetted bowl typically requires rim channel assistance, especia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com