Product producible number calculation apparatus and computer-readable recording medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

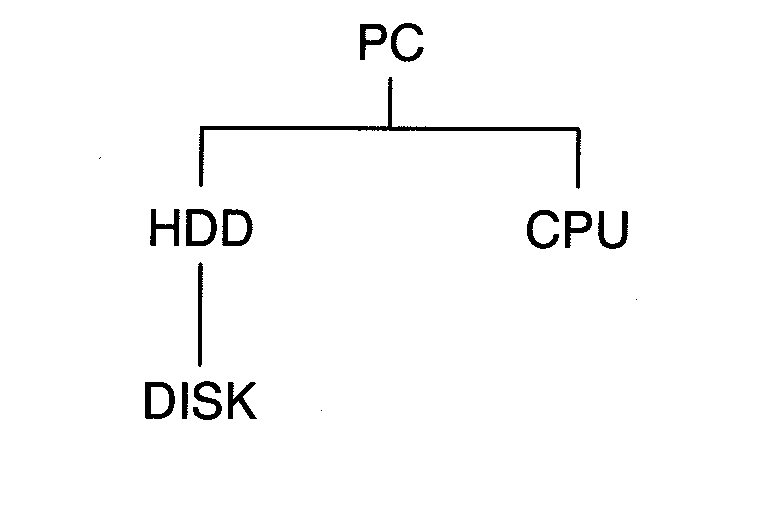

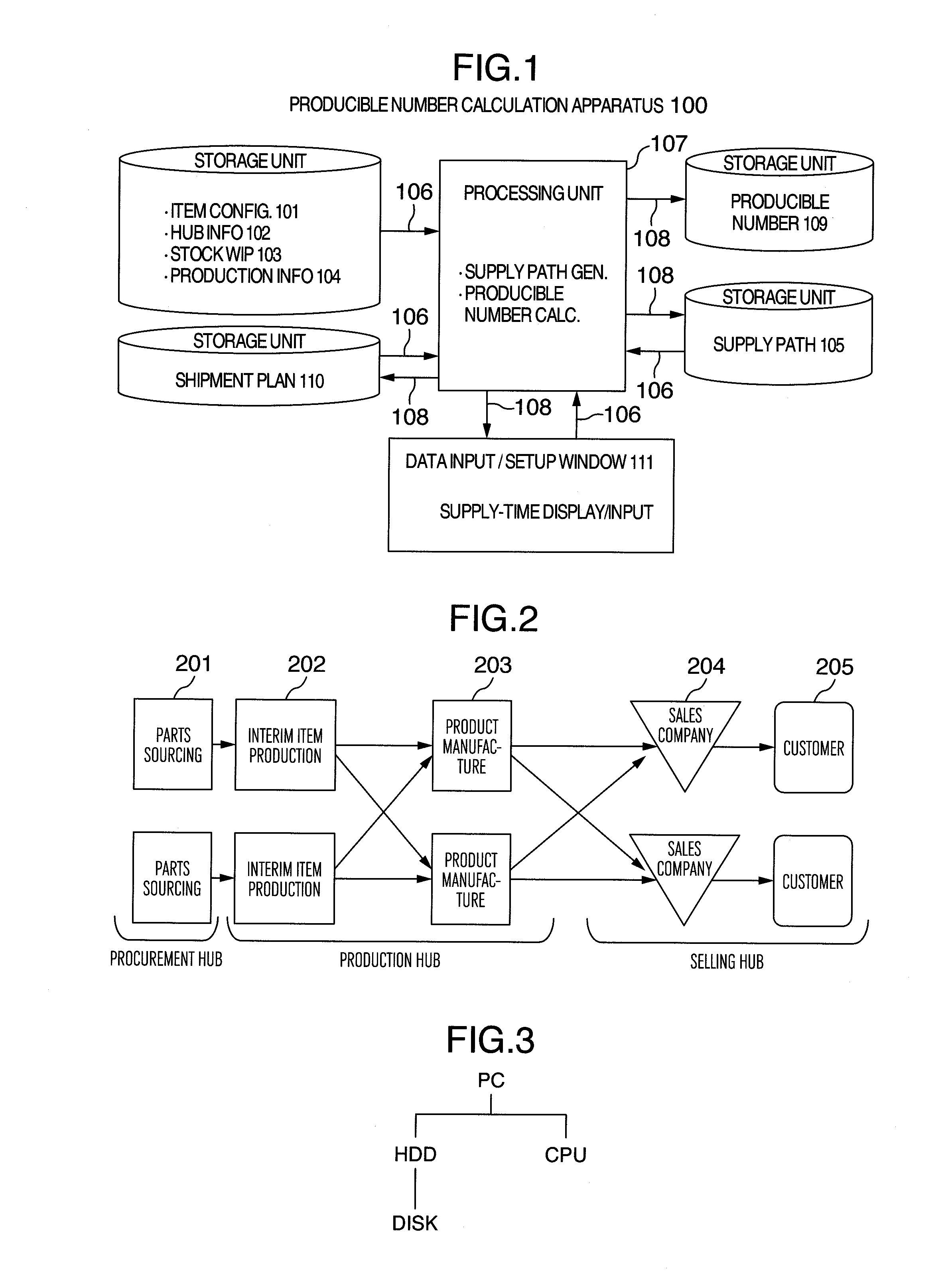

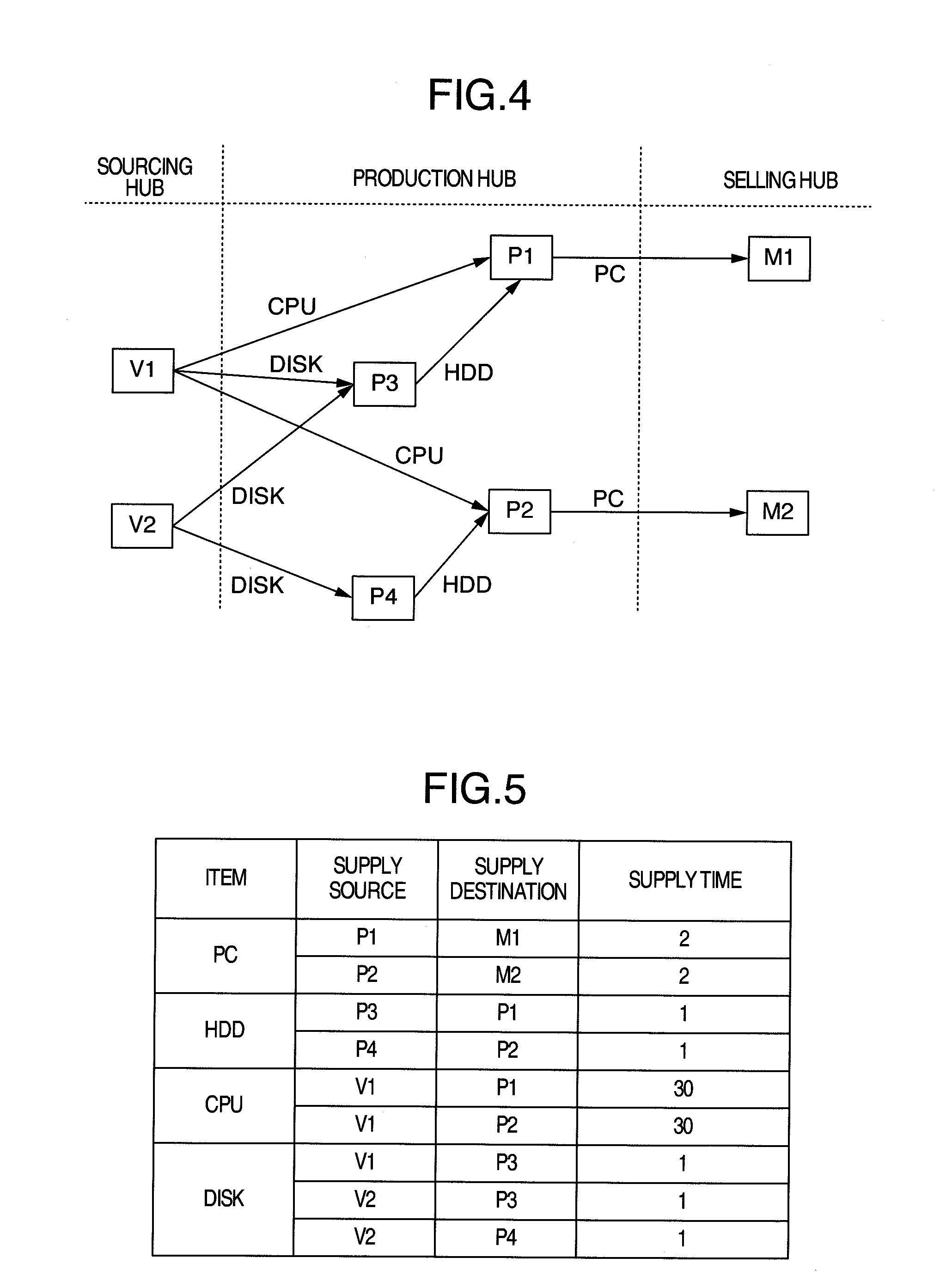

[0043]A producible number calculation apparatus in accordance with one embodiment of the present invention will be described with reference to the accompanying drawings below.

[0044]An explanation will first be given, using FIG. 2, of a flow of things from a manufacturing base point, also known as production hub, to a selling site or hub. At the production hub, several works are performed, including procurement (201) of parts or components, production (202) of large-structure semimanufactured products from the parts, production (203) of finished products from such semimanufactured ones, and shipment of these products, which are once delivered to sales companies (204) existing at selling hubs and then distributed to customers (205). In cases where the products are not assemblies, for example, in the case of food oil or like substance, wherein the aforesaid component corresponds to crude, the semimanufactured product is purified oil, and the finished product is a bottle of oil, the gen...

embodiment 2

[0085]In a second embodiment, an explanation will be given of an example of producible number calculation apparatus which calculates a producible number and cost by using utilizable supply paths. FIG. 16 shows an exemplary configuration of producible number calculation apparatus 1600 in the embodiment 2. Constituent elements or units of apparatus 1600 which are similar in function to those shown in FIG. 1 are designated by the same reference numerals, and their explanations are eliminated herein.

[0086]The producible number calculation apparatus 1600 has, in addition to the functional components of the apparatus 100 shown in FIG. 1, an inter-hub cost storage unit 1601 which stores therein a cost between hubs, a cost storage unit 1603 that stores cost data, and a cost upper-limit storage unit 1602 storing, when needed, an upper limit value of product cost on a per-hub basis. A hardware structure of the apparatus 1600 is similar to that of the apparatus 100 shown in FIG. 15.

[0087]Next,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com