Multilayer film and cell culture container

a cell culture container and multi-layer technology, applied in the field of cell culture technology, can solve the problems of inability to achieve a high degree of cell density, and insufficient gas permeability of a conventional culture bag, so as to improve cell proliferation efficiency and improve gas permeability of the cell culture container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

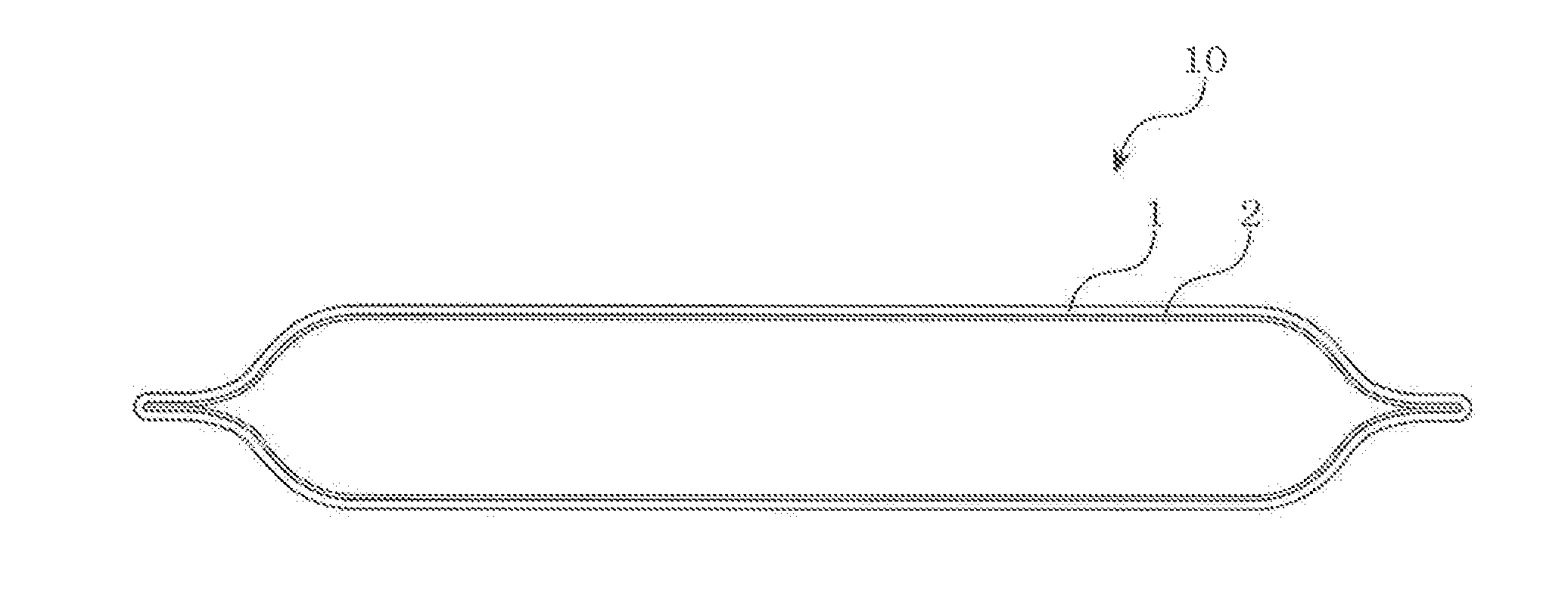

[0027]The multilayer film and the cell culture container according to the first embodiment of the present invention will be explained with reference to FIG. 1 and FIG. 2. FIG. 1 is a view showing the configuration of the multilayer film of this embodiment, and FIG. 2 is a view showing the configuration of a cell culture container formed by the multilayer film of this embodiment.

[0028]As shown in FIG. 1, the multilayer film of this embodiment is used for forming a cell culture container, and has a base material 1 forming the main body part of the cell culture container and an inner layer 2 (innermost layer) forming the cell culture surface.

[0029]The base material 1 and the inner layer 2 are formed of a material having a high gas permeability, heat sealing properties and transparency. The inner layer 2 is formed of a material having a low cytotoxicity in addition to the above-mentioned properties. As examples of such a material, a polyethylene-based resin such as linear low density po...

second embodiment

[0047]Then, the multilayer film and the cell culture container according to the second embodiment of the present invention will be explained with reference to the drawings. FIG. 3 is a view showing the configuration of the multilayer film of this embodiment, and FIG. 4 is a view showing the configuration of the cell culture container formed by the multilayer film of this embodiment.

[0048]In this embodiment, the multilayer film has a configuration in which a polyethylene-based resin having a density of 0.886 g / cm3 to 0.93 g / cm3 is used as an outer layer 3 in the first embodiment. In the multilayer film of this embodiment, one or two or more outer layers may be provided between the base material 1 and the outer layer 3. Further, between the base material 1 and the inner layer 2, one or two or more inner layers may be provided.

[0049]If the density of the outer layer 3 is smaller than 0.886 g / cm3, production and handling of a cell culture container using the multilayer film may become m...

example 1

[0058]A cell culture film formed of three layers was subjected to co-extrusion molding by the T-die method by using a labo plastomill (manufactured by Toyo Seiki Co., Ltd.). At this time, as the base material, Kernel KS240T (LLDPE, manufactured by Japan Polyethylene Corporation, density, 0.880 g / cm3) was used. As the inner layer and the outer layer, a resin obtained by blending Excellen GMHCB 2001 (LDPE, manufactured by Sumitomo Chemical Corporation, density, 0.920 g / cm3) and Kernel KM 262 (LLDPE, manufactured by Japan Polyethylene Corporation, density, 0.898 g / cm3) at an amount ratio of 6:4 was used. In the cell culture film thus produced, the thickness of the base material was 66 μm, the thickness of the inner layer was 19 μm, the thickness of the outer layer was 12 μm, and the total thickness of the cell culture film was 97 μm.

[0059]By using this cell culture film, the oxygen permeability per unit thickness (ml·mm / m2·day·atm (37° C.-80% RH)) was measured by means of a gas permeab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com