Time Delay With Control Voltage Sensing

a technology of time delay and control voltage, which is applied in the direction of space heating and ventilation control systems, lighting and heating apparatuses, and compressor types, etc., can solve the problems of compressor stalling, protection devices may not be able to prevent thermal damage to compressors, and the time necessary to trigger protection devices may be multiplied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]It should be understood at the outset that although an illustrative implementation of one or more embodiments are provided below, the disclosed systems and / or methods may be implemented using any number of techniques, whether currently known or in existence. The disclosure should in no way be limited to the illustrative implementations, drawings, and techniques illustrated below, including the exemplary designs and implementations illustrated and described herein, but may be modified within the scope of the appended claims along with their full scope of equivalents.

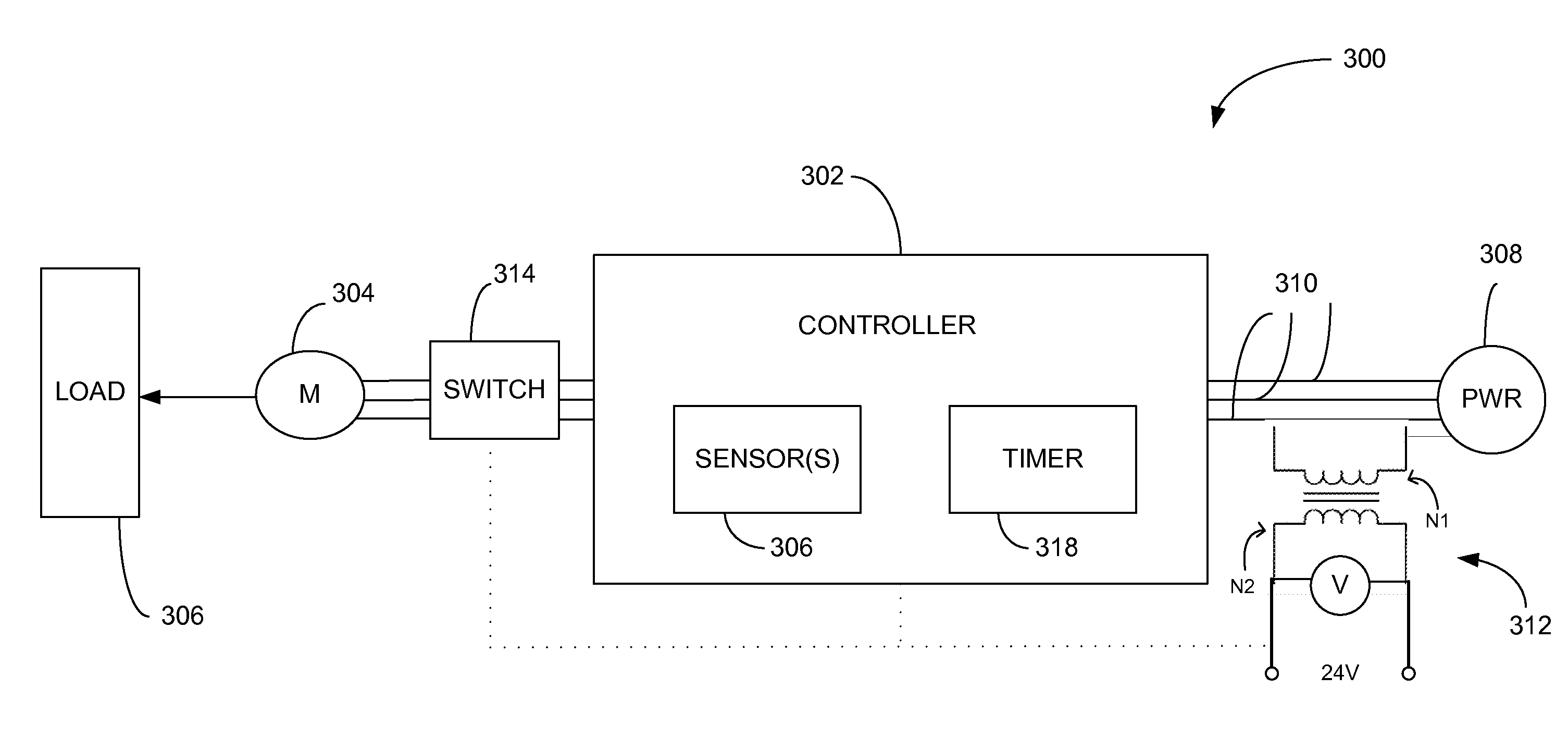

[0018]Disclosed herein is a system and method for controlling operation of an air conditioning unit. In an embodiment, the system comprises a controller configured to monitor a supply of control voltage that is derived from line voltage, which supplies power to a motor. In response to detecting a reduction in control voltage, the controller may deactivate the motor if an increase in control voltage is not detected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com