White Metal Babbitt for Rolling Mill Bushing

a technology of white metal babbitt and rolling mill bushing, which is applied in the direction of shafts, bearings, rotary machine parts, etc., can solve the problems of low fatigue resistance, limited load capacity of bearings made with this material, and alloys that cannot be readily drawn into wire for spray welding applications, etc., and achieves low toxicity.

Inactive Publication Date: 2013-04-04

SIEMENS IND INC

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patent is about a new kind of metal alloy that is safe and doesn't contain any harmful substances like cadmium. It's made up of tin, which is a safe element to have in large amounts in humans. The benefit of this new alloy is that it's safer and more stable than other similar alloys, which can be toxic and carcinogenic.

Problems solved by technology

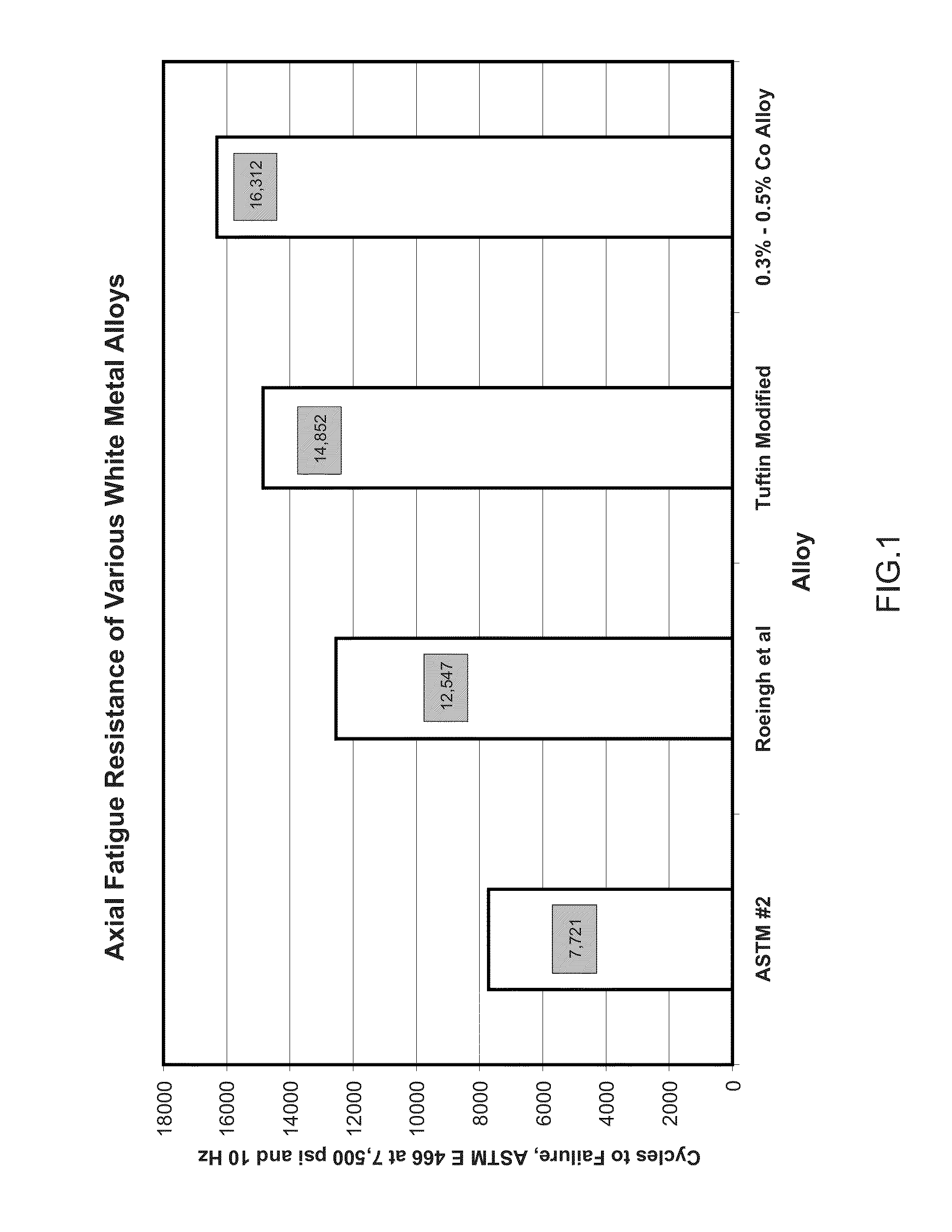

Unfortunately, ASTM #2 has relatively low fatigue resistance, which limits load capacity of bearings made with this material.

These alloys can be cast and welded, but they contain Nickel, which is a heavy metal that is undesirable for environmental reasons.

But due to the brittleness of the zinc component, this alloy cannot be readily drawn into wire for use in spray and welding applications.

Cadmium is a known carcinogen that has been banned from most workplaces and thus is undesirable.

The inclusion of chrome is impractical as it is not readily soluble under normal alloying conditions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example ii

[0023]

Antimony6.0-8.0% by weightCopper3.0-8.0% by weightCobalt0.1-0.7% by weightTinBalance

example iii

[0024]

Antimony6.0-8.0% by weightCopper6.0-7.0% by weightCobalt0.1-0.7% by weightTinBalance

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Login to View More

Abstract

Description

CROSS REFERENCE TO RELATED APPLICATION[0001]This application claims benefit, under 35 U.S.C. §119(e), of U.S. Provisional Application Ser. No. 61 / 541,395, filed 30 Sep. 2011, the entire contents and substance of which is hereby incorporated by reference.BACKGROUND[0002]1. Field[0003]Embodiments and aspects of the present invention relate to tin based white metal alloys useful in various industrial applications, including the bushings of rolling mill oil film bearings.[0004]2. Description of Related Art[0005]The most prominent white metal alloy used in oil film bearings in the rolling mill field is described in ASTM B23 #2, (referred to here as ASTM #2) and is comprised primarily of tin, with antimony and copper, as alloying elements. ASTM #2 is well understood and is readily deposited onto bushing shells via centrifugal casting, spray deposition, or welding. Unfortunately, ASTM #2 has relatively low fatigue resistance, which limits load capacity of bearings made with this material.[...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C13/02C22C13/00

CPCC22C13/00C22C13/02F16C2204/34F16C2322/12F16C33/06F16C33/121

Inventor SEELIG, KARL F.

Owner SIEMENS IND INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com