Channel lock filter fastening system for use with an air intake structure

a filter and air intake technology, applied in the field of channel lock construction, can solve the problems of increasing the cost of filters, significant effort and time, both mounting time and effort, and achieve the effect of quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

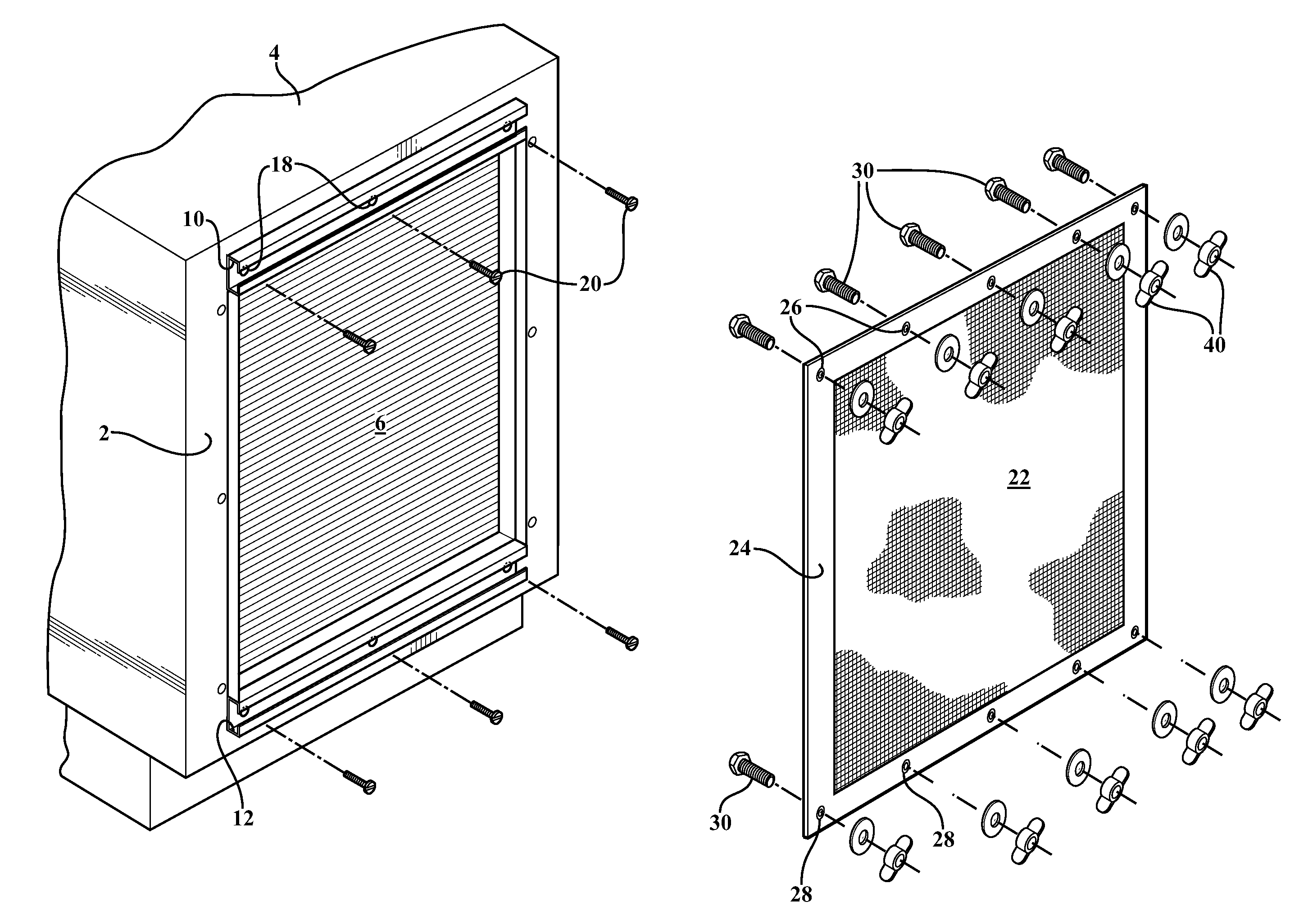

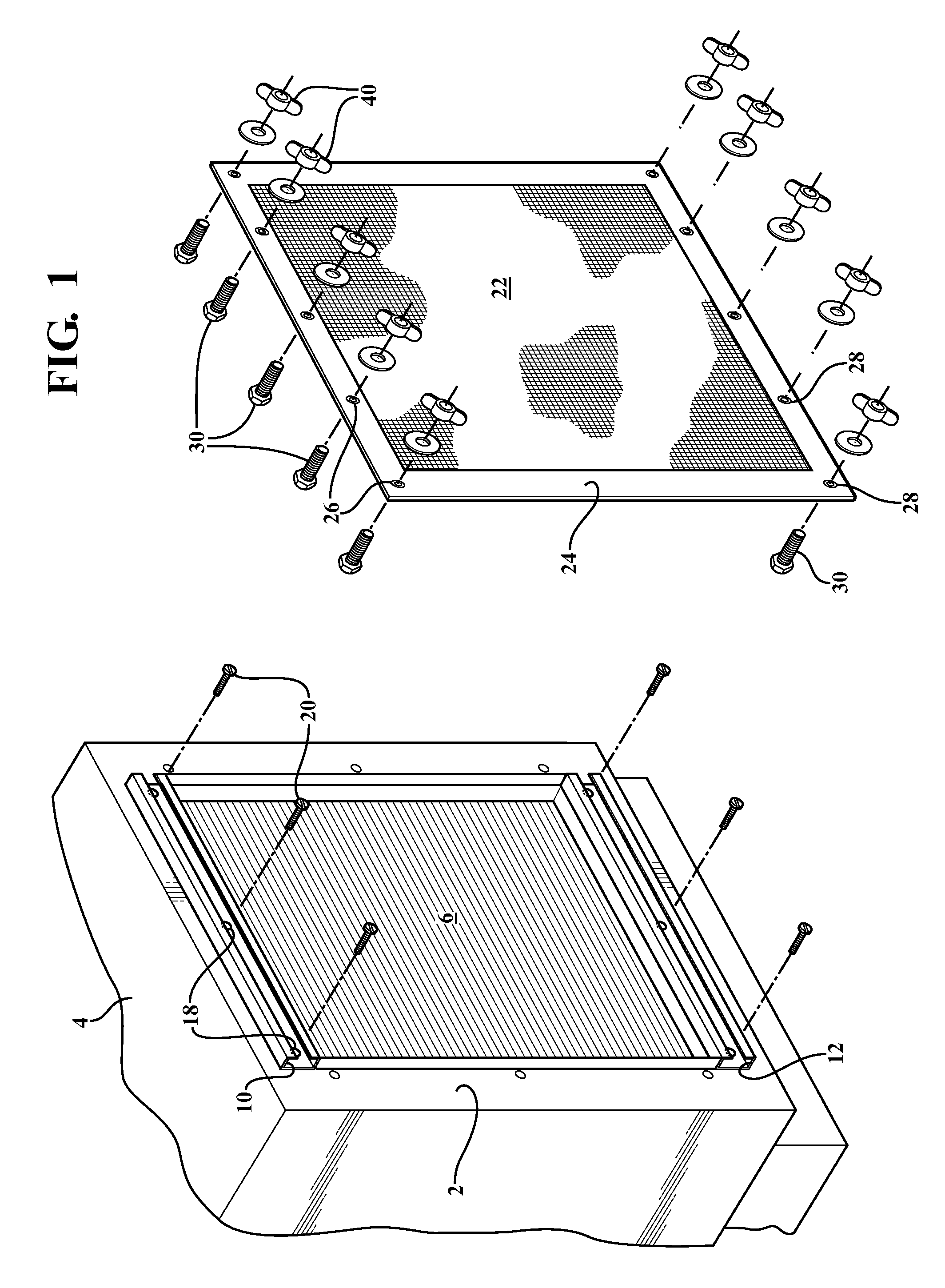

[0032]Referring to FIG. 1, an exploded view is generally depicted of the channel lock filter fastening system according to the present invention and exhibiting a single pair of upper and lower horizontal extending and fascia supporting rails, see at 10 and 12, which are secured at extending locations along a fascia surface 2 associated with an air intake structure 4 (such further understood to include any suitable type of air handling mechanical equipment not limited to air conditioner condenser units, cooling towers etc.). As further depicted in each of succeeding views FIGS. 3-6, each of the rails (see for example first upper horizontal extending rail 10) exhibits a three dimensional, and typically modified “U”, shape with a base surface (see at 14 in each of FIGS. 3-6).

[0033]A plurality of spaced apart apertures are defined by inner perimeter extending circular edges 18 (see again rail 10 in each of FIGS. 1 and 2). A plurality of screw fasteners 20 are provided and insert through...

second embodiment

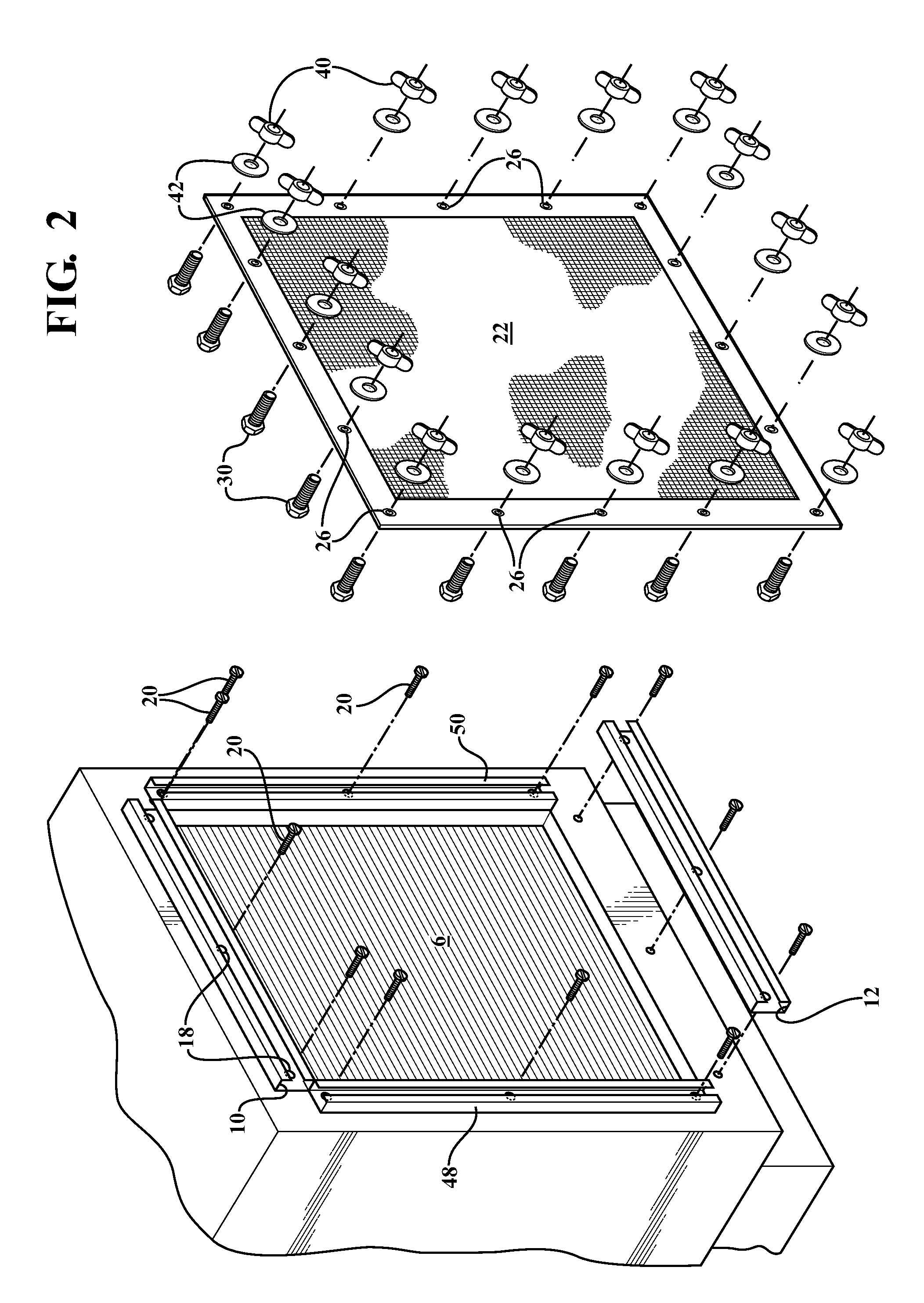

[0038]FIG. 2 is a view similar to FIG. 1 of a system which differs only to the extent that it adds a second vertical pair of intake face mounted rails 48 and 50 applied to opposite and vertically extending sides of the fascia 2 in such a fashion that the first (10 and 12) and second pairs (48 and 50) of rails collectively establish a generally rectangular shape (this including a square shape in the instance in which the sides of the intake opening and the lengths of all the rails are co-equal). Otherwise, the filter 22 is as previously disclosed in claim 1 with the corresponding modification to include additional grommets 26 likewise extending along the vertical side edges of the reinforced outer frame (also hem or skirt) with corresponding additional bolts 30, wing nuts 40 and washers 42 likewise being provided so as to progressively secure the filter 22 along each of four interconnecting edges and as opposed to only two upper and lower edges as is the case in the illustration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com