Hermetic sealing system for containers

a sealing system and container technology, applied in the direction of containers, caps, gas/liquid distribution and storage, etc., can solve the problems of wear on the system and its random detachment, high probability of accidents, and high cost of equipment, so as to ensure the tightness of the assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

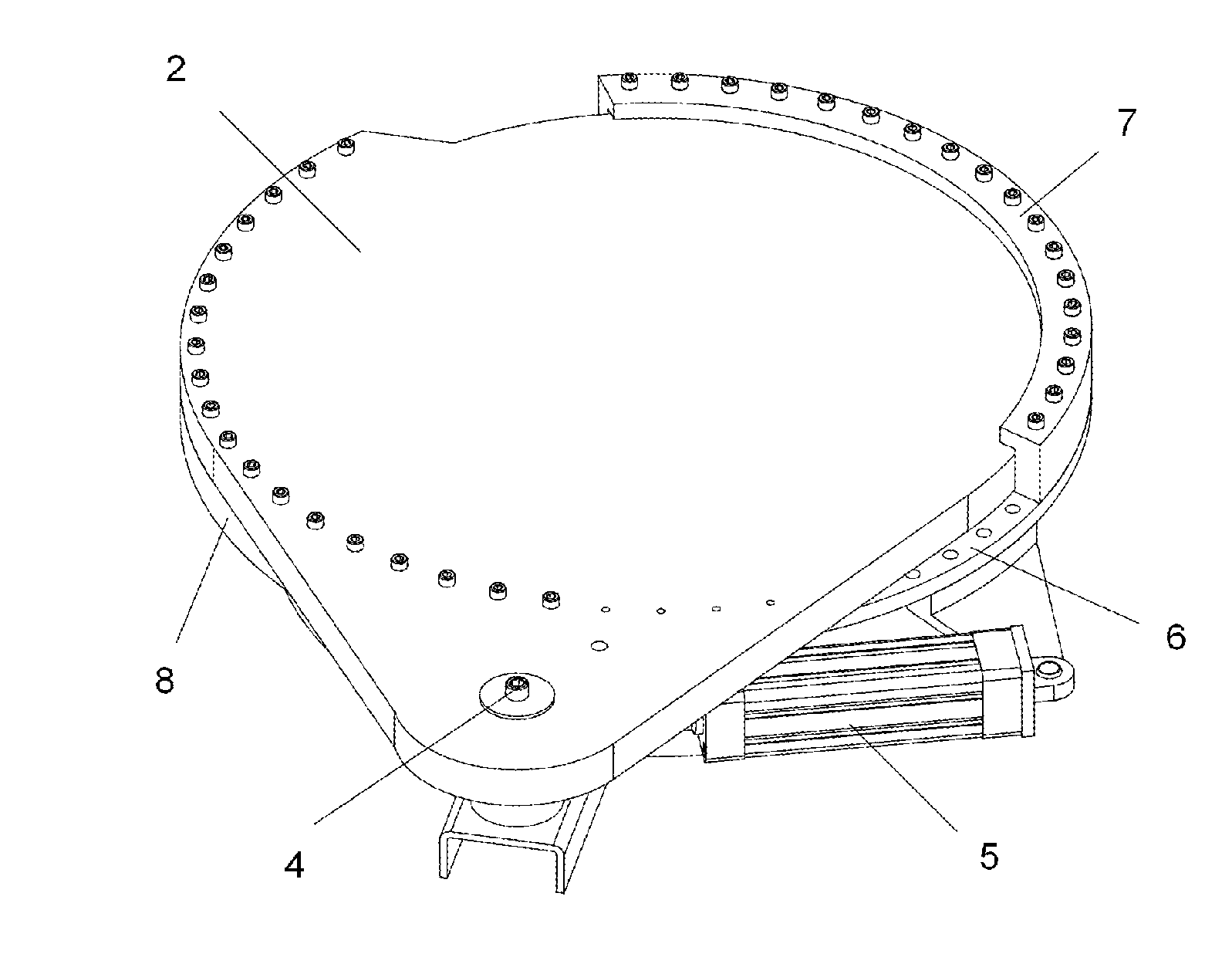

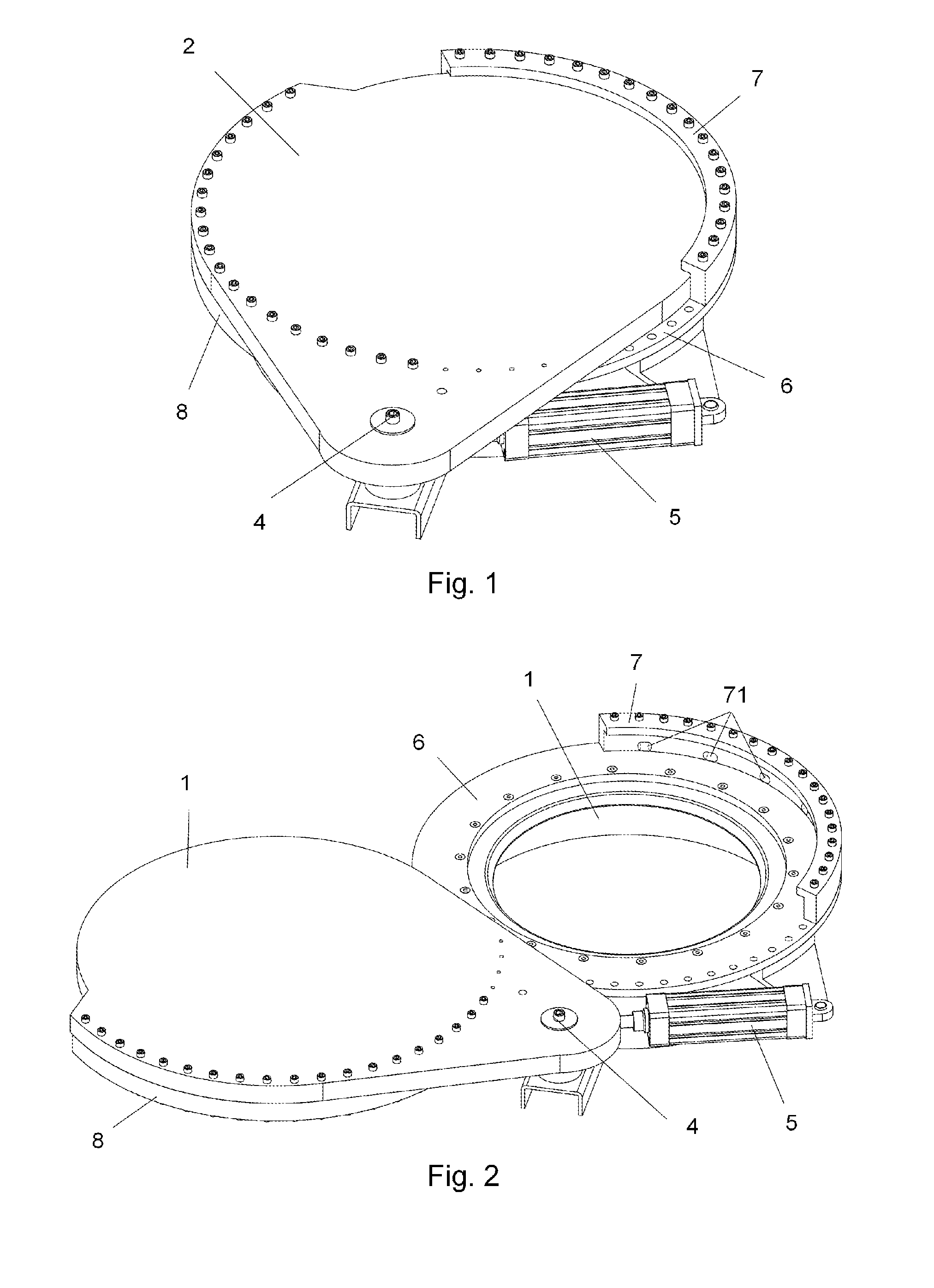

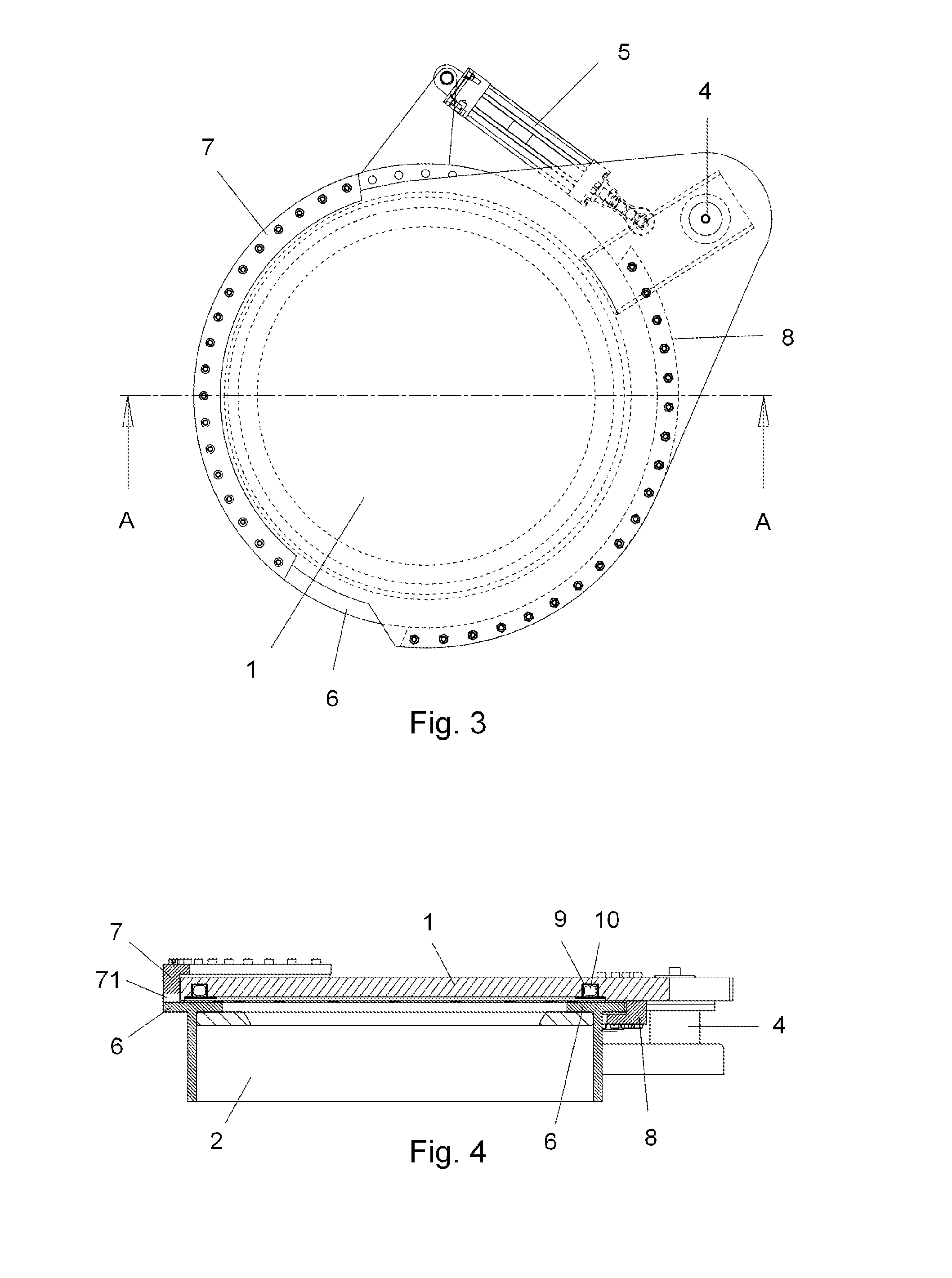

[0012]The hermetic sealing system for containers, object of the invention, of the type comprising a lid that moves in a plane parallel to the mouth of the container, means of activating the lid between the open and closed positions, and a pneumatic seal which acts on the surfaces opposite the lid and the mouth in the closed position, presents constructive features aimed at securing the lid, in the closed position, with respect to the mouth, preventing its perpendicular movement with respect to the plane of the mouth, ensuring proper sealing of the closure by the pneumatic seal.

[0013]Another objective of the invention is to allow remote control of the means for activating the lid, in order to facilitate opening and closing actions by the user and to prevent accident risks involving user access to the top area of the container due to manually carrying out the opening and closing manoeuvres.

[0014]To this end, according to the invention, the mouth of the container has at its upper end a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com