Electret condenser microphone

a condenser microphone and condenser technology, applied in the direction of loudspeakers, transducer types, microphone structural associations, etc., can solve the problems of very important cost considerations, and achieve the effect of low manufacturing cost and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

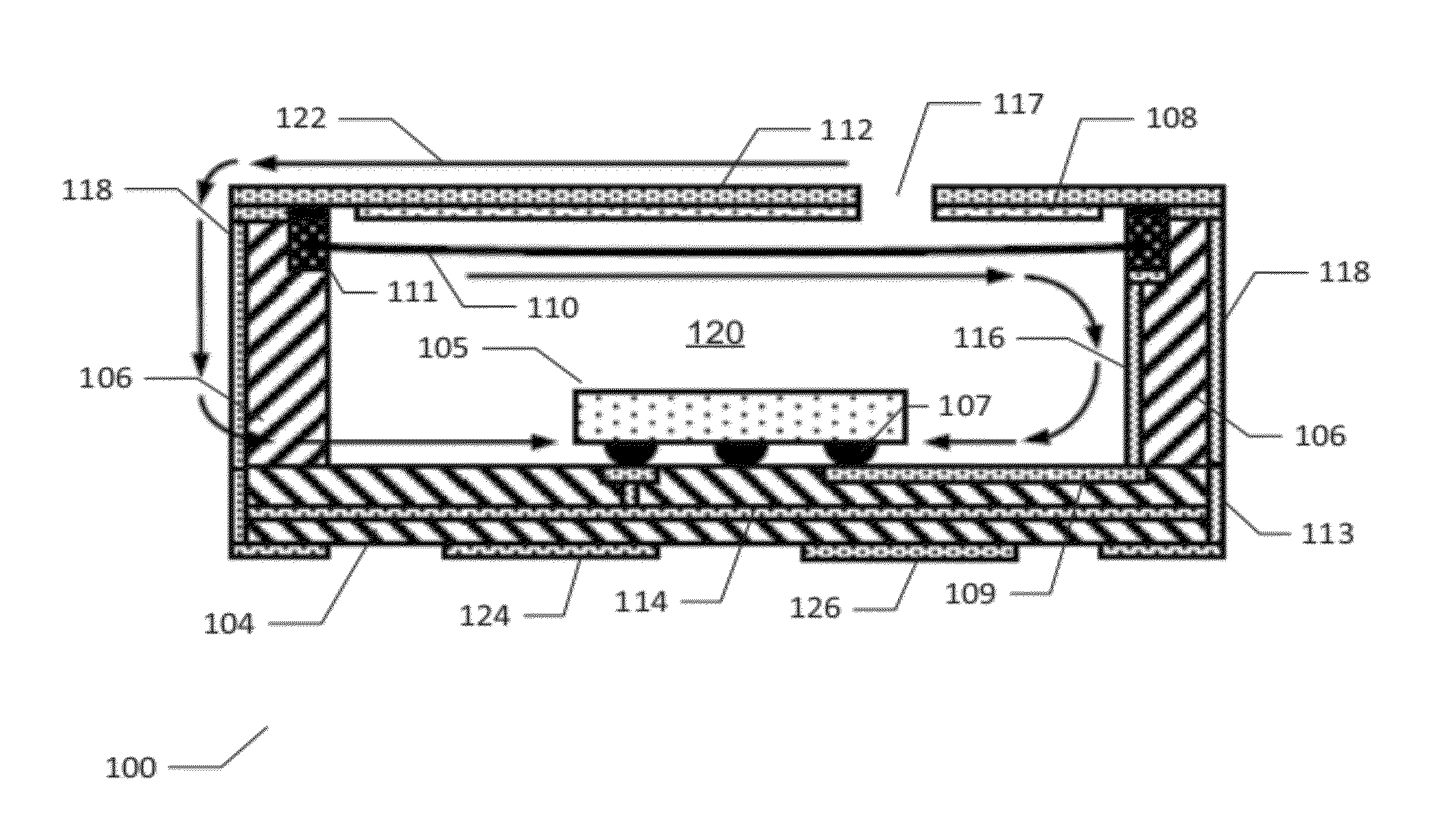

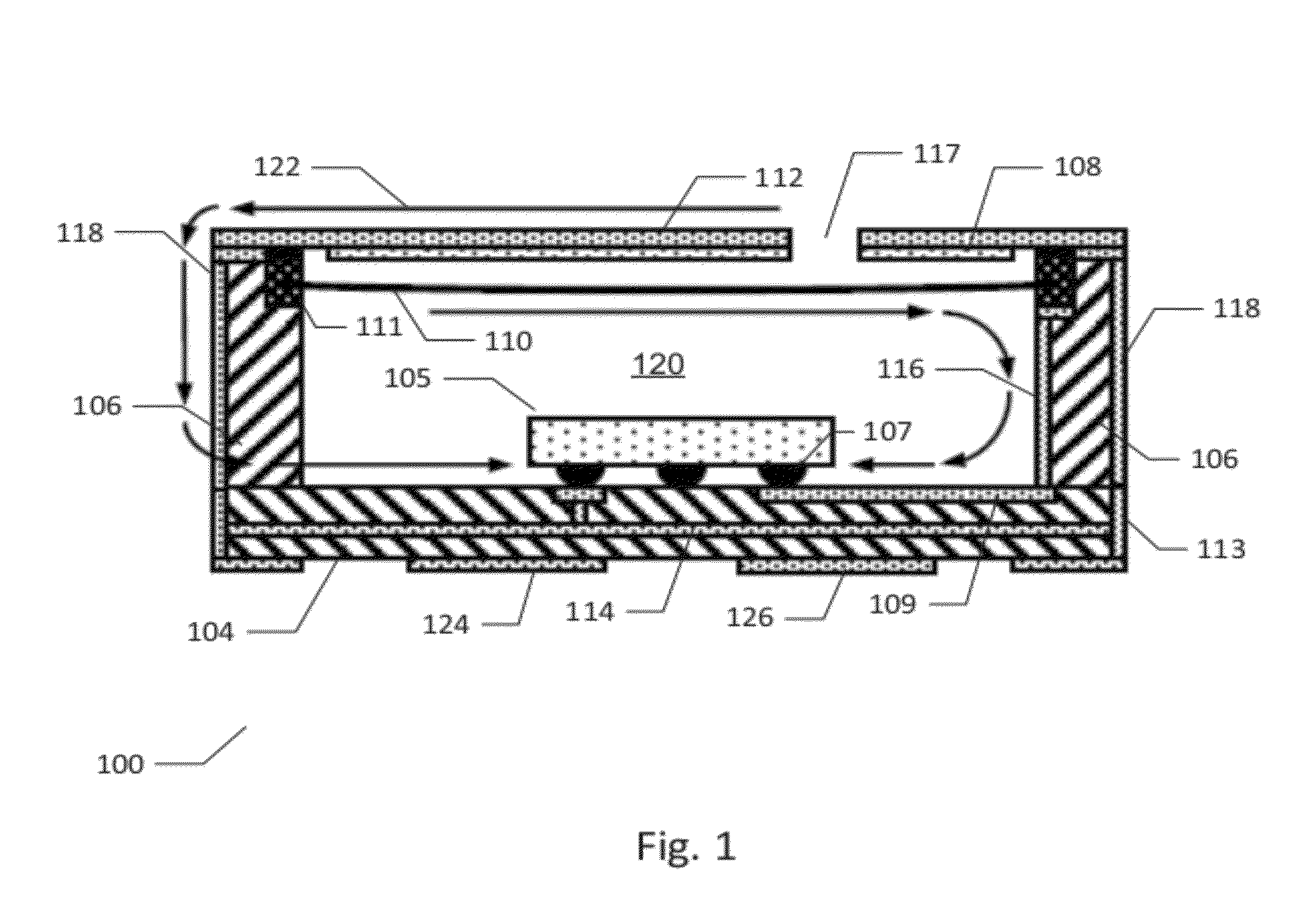

[0029]FIG. 1 is a vertical cross-sectional view of an electret condenser microphone (ECM) 100 according to the invention. The ECM 100 comprises a carrier 104 that may comprise a single layer or multi-layer printed circuit board or a ceramics substrate. The carrier 104 comprises first and second mutually insulated electrical traces or wires. The first electrical trace 109 is disposed on an upper surface of the carrier 104 also carrying or supporting a microphone preamplifier 105. A microphone preamplifier is provided on a semiconductor die or substrate 105. The microphone preamplifier may be integrated on an Application Specific Integrated Circuit (ASIC) fabricated in a sub-micron CMOS semiconductor process technology. The semiconductor die 105 is attached to the upper surface of the carrier 104 through a set of preamplifier pads or terminals which mate to a set of carrier pads A first preamplifier terminal 107 is an audio input of the microphone preamplifier 105 and the audio input ...

second embodiment

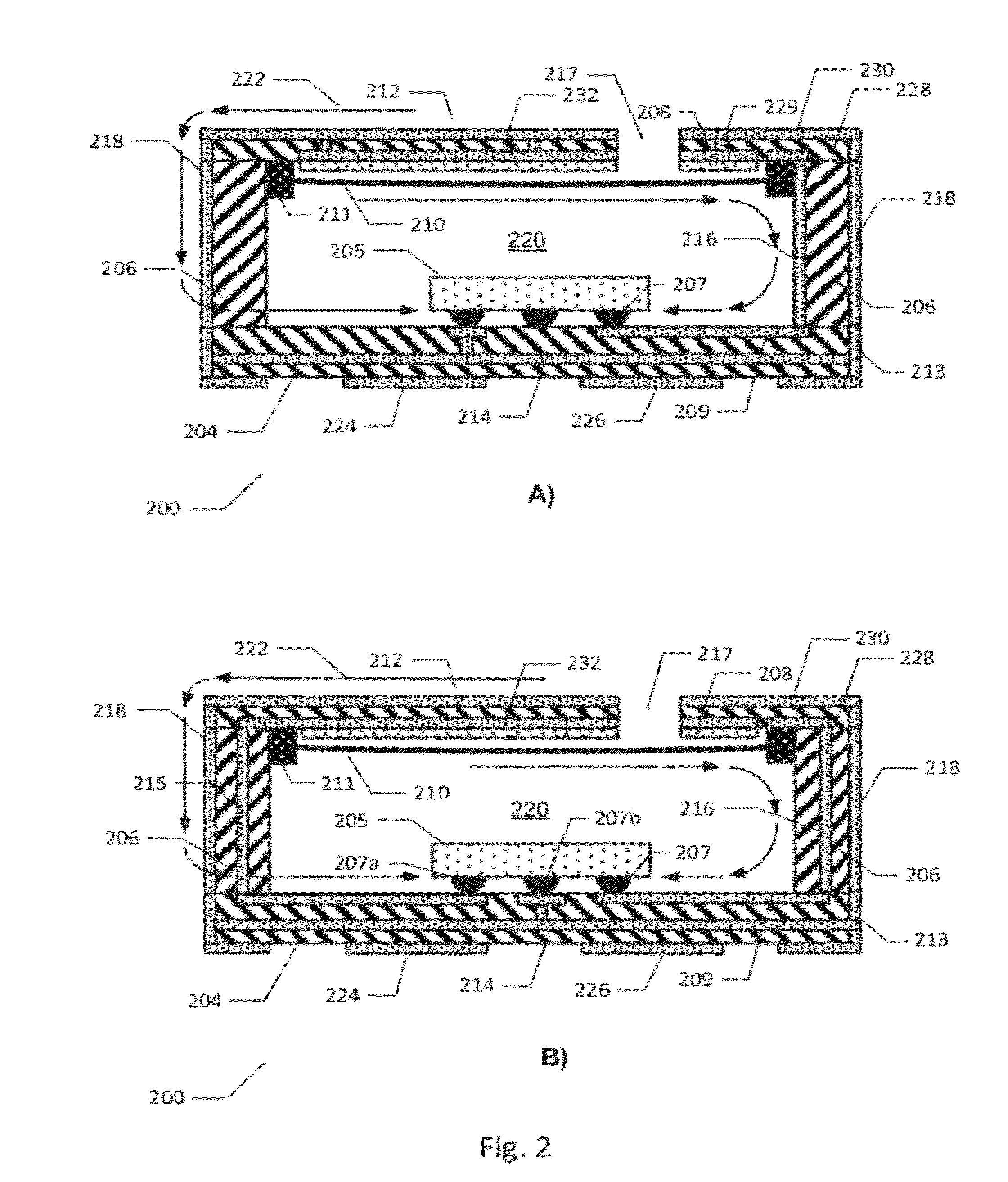

[0037]FIG. 3 is a schematic exploded view of the ECM 200 described above in accordance with the invention. The ECM housing is formed exclusively by three separate members, i.e. the carrier 204, the exterior sidewall structure 206 and the lid structure 212 which jointly form a substantially closed microphone housing. Furthermore, each of the carrier 204, the exterior sidewall structure 206 and the lid structure 212 is preferably fabricated in PCB material using conventional PCB manufacturing processes and technology to provide a low-cost housing structure. Furthermore, electrical wiring patterns provided on the outside surfaces of, or inside, the exterior sidewall structure 206 provide electrical interconnection between the conductive microphone diaphragm 210 (refer to FIG. 2) and the backplate structure, formed integrally with the lid structure 212, and the microphone preamplifier integrated on the ASIC 205. The adaptation of the exterior sidewall structure 206 to provide this type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com