Shoulder strap and neck strap comprised of an oblong shaped pad and a strap

a shoulder strap and oblong shaped technology, applied in the field of shoulder straps, to achieve the effect of reducing load, reducing pressure on the vertebrae, and improving weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The present invention is described with reference to FIGS. 1-4, where like parts are referred to using like character references.

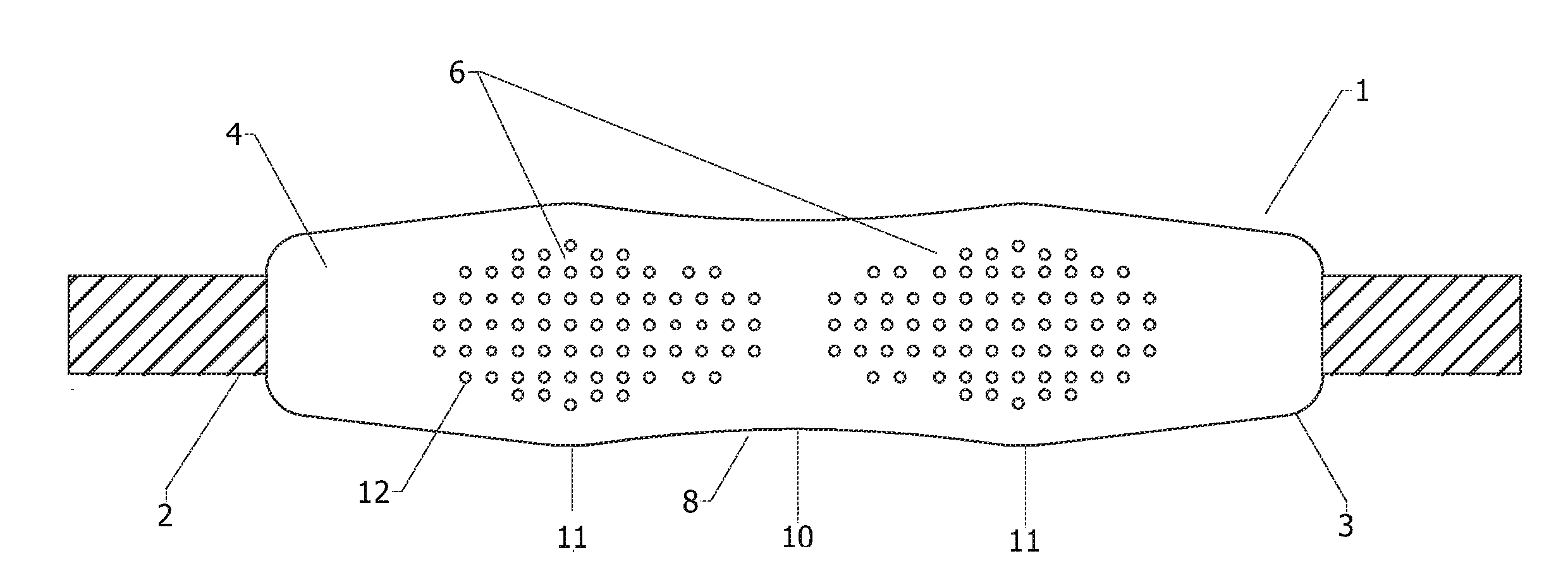

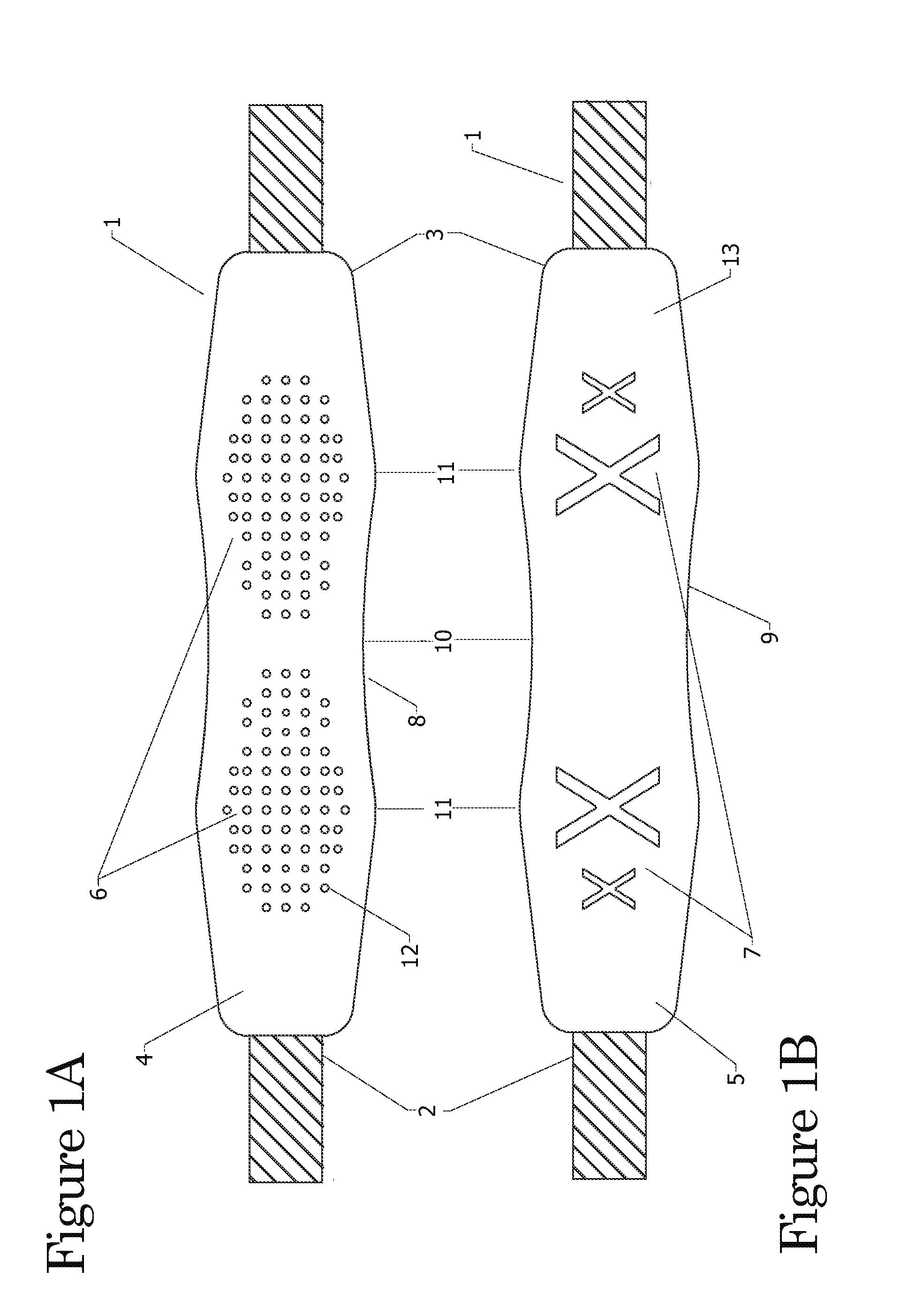

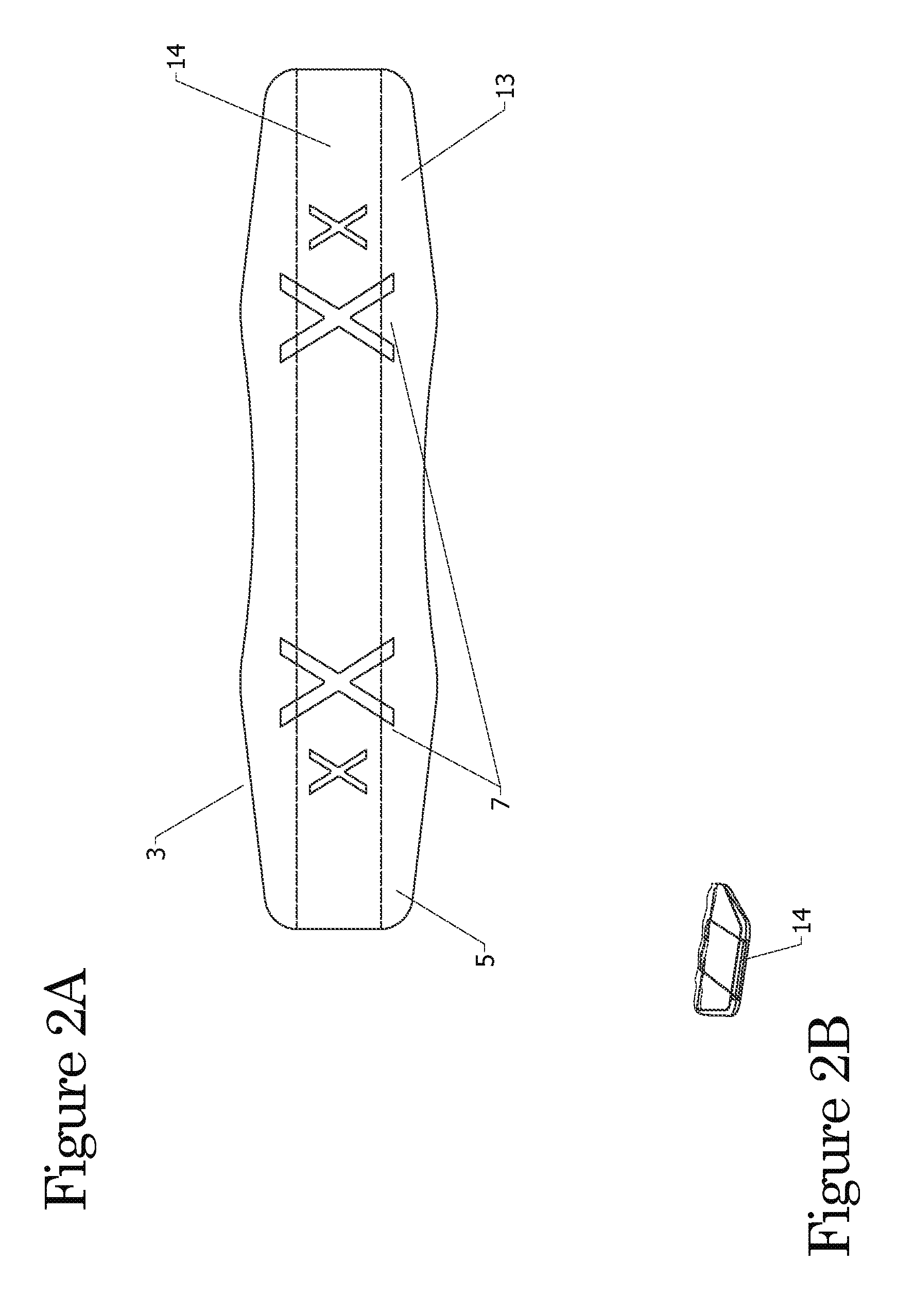

[0018]FIGS. 1A and 1B illustrates a dual function shoulder and neck strap (1) having a strap member (2) and a pad member (3) that is hot compression molded to the strap member (2). The pad member (3) has a front side (4) and a back side (5). A NSTNP (6) is formed on the front side (4) of the pad member (3), and perspiration collecting grooves (7) are formed in the back side (5) of the pad member (3).

[0019]The front side (4) of the pad member (3) may also have a first concave curved portion (8). The first concave portion (8) is configured to allow pad member (11) to rest on a larger area of the trapezius muscle of the wearer when the strap is in use, rather than on the accessory nerve at the peak of the shoulder. The wider sections of the pad member (11) in conjunction with the NSTNP (6) creates a friction and gripping effect that redistributes the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com