Liquid radiation curable resins for additive fabrication comprising a triaryl sulfonium borate cationic photoinitiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0104]These examples illustrate embodiments of the liquid radiation curable resins for additive fabrication of the instant invention. Table 1 describes the various components of the liquid radiation curable resins for additive fabrication used in the present examples.

TABLE 1Function inComponentFormulaChemical DescriptorSupplierBYK A 501Bubble breakerNaphtha / methoxy propanol acetateBYK-ChemieNK Ester A-DOGFree radical[2-[1,1-dimethyl-2-[(1-Kowapolymerizableoxoallyl)oxy]ethyl]-5-ethyl-1,3-dioxan-compound5-yl]methyl acrylateCD 406Free radical1,4-Cyclohexanedimethanol diacrylateSartomerpolymerizablecompoundChivacure 1176CationicA mixture of: bis[4-ChitecPhotoinitiatordiphenylsulfoniumphenyl]sulfidebishexafluoroantimonate;thiophenoxyphenylsulfoniumhexafluoroantimonate and propylenecarbonate.Chivacure BMSPhotosensitizing[4-[(4-Chitecagentmethylphenyl)thio]phenyl]phenyl-methanoneDG-0071Stabilizer22% of sodium carbonate solutionDesotechDPHARadicalDipentaerythritol hexaacrylateSigmaPolymeriz...

examples 1-7

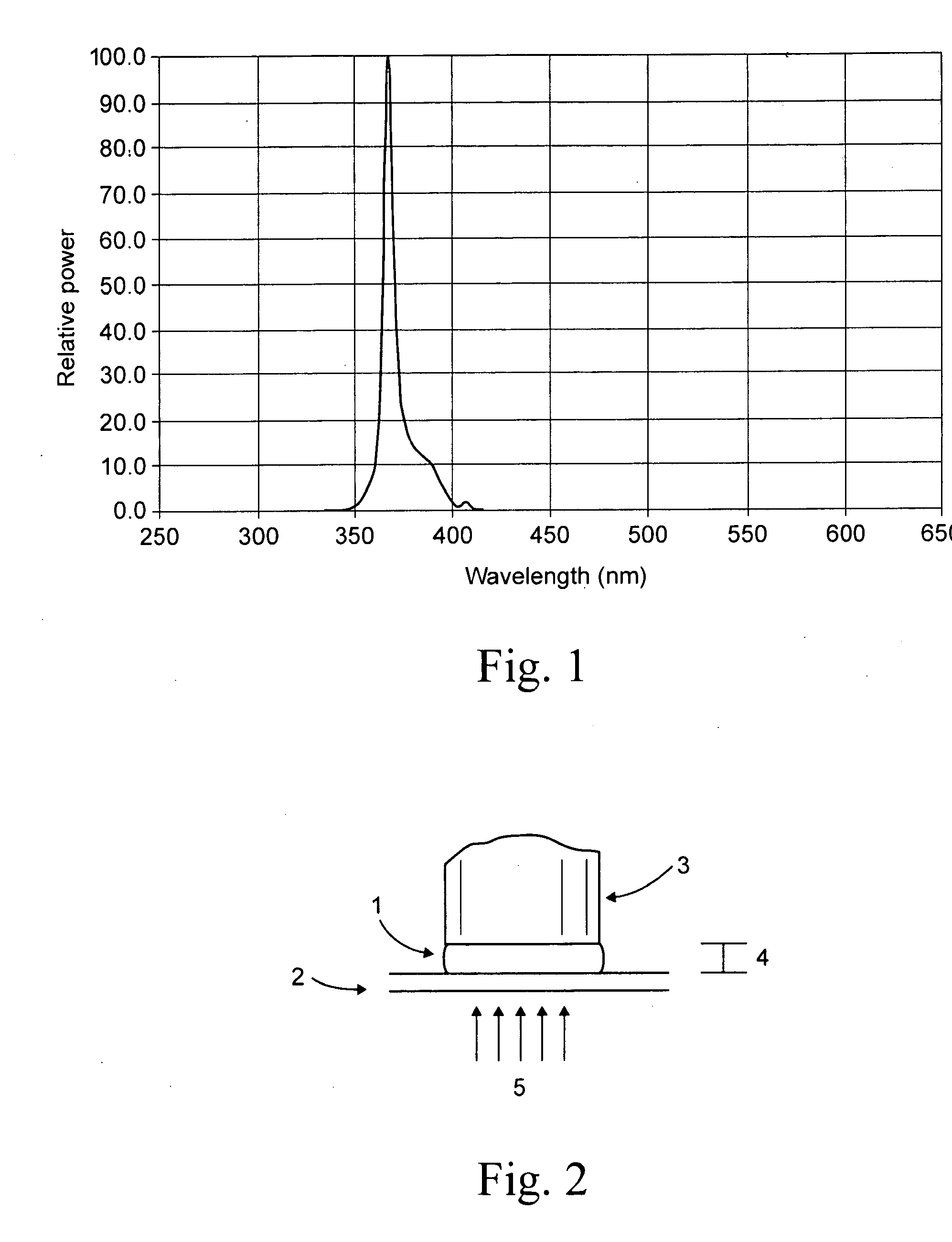

[0105]Various liquid radiation curable resins for additive fabrication were prepared using an R-substituted aromatic thioether triaryl sulfonium tetrakis(pentafluorophenyl)borate cationic photoinitiator. A similar composition was prepared using an alternative antimony-free cationic photoinitiator. These samples were tested according to the methods for working curve measurement and dynamic mechanical analysis detailed below. Working curve data was obtained using a single UV LED “bare bulb” (Model No. NCSU033A; Nichia Corporation, Japan) having a peak wavelength of 365 nm in a light curing apparatus, wherein the single LED light is bottom-mounted on a flat surface inside a 30° C. chamber and positioned in an upward-looking arrangement and pointing vertically according to the below method. Real-time dynamic mechanical analysis was performed using a mercury lamp with a 365 nm interference filter, respectively. The results are presented in Table 2 and Table 3.

[0106]Working Curve Measurem...

examples 8-11

[0114]Various liquid radiation curable resins were prepared according to methods well known in the art. The amount and type of the cationic photoinitiator was varied from Chivacure 1176 (Comparative Examples 8, 9, 10) to Irgacure PAG-290 (Examples 8, 9, 10, 11). Since Chivacure 1176 is a 50 / 50 mixture of cationic photoinitiator and propylene carbonate, an amount of propylene carbonate was added to some of the formulations containing PAG-290 in order to keep the amount of cationic photoinitiator plus propylene carbonate constant. Working curve data was prepared using a solid state laser operating at a wavelength of 354.7 nm in accordance with the below method. Photo-stability data (hrs until gel time), and thermal-stability data (initial viscosity, 15 day viscosity, and 24 days viscosity) were measured in accordance with the below methods. The details of the compositions of each example (Ex) and comparative example (Comp) are specified in Table 4 with each component represented as we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com