Method of Processing Green Coffee Beans

a technology of green coffee beans and green coffee beans, which is applied in the field of processing green coffee beans, can solve the problems of insufficient improvement of the flavor and aroma of coffee beans, and achieve the effects of rich aroma and flavor, improved flavor and aroma of green coffee beans, and good aroma and flavor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

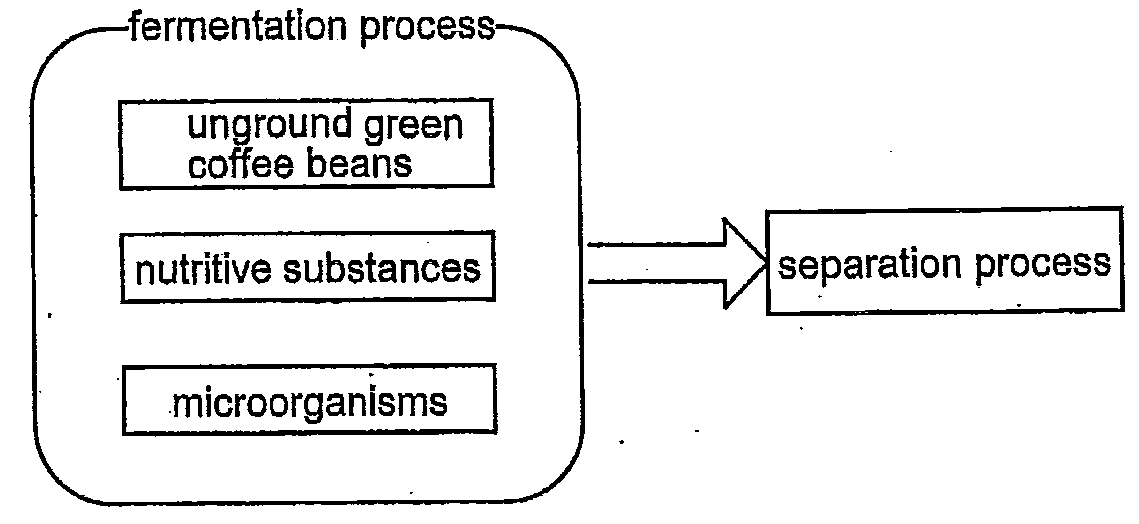

Method used

Image

Examples

embodiment 1

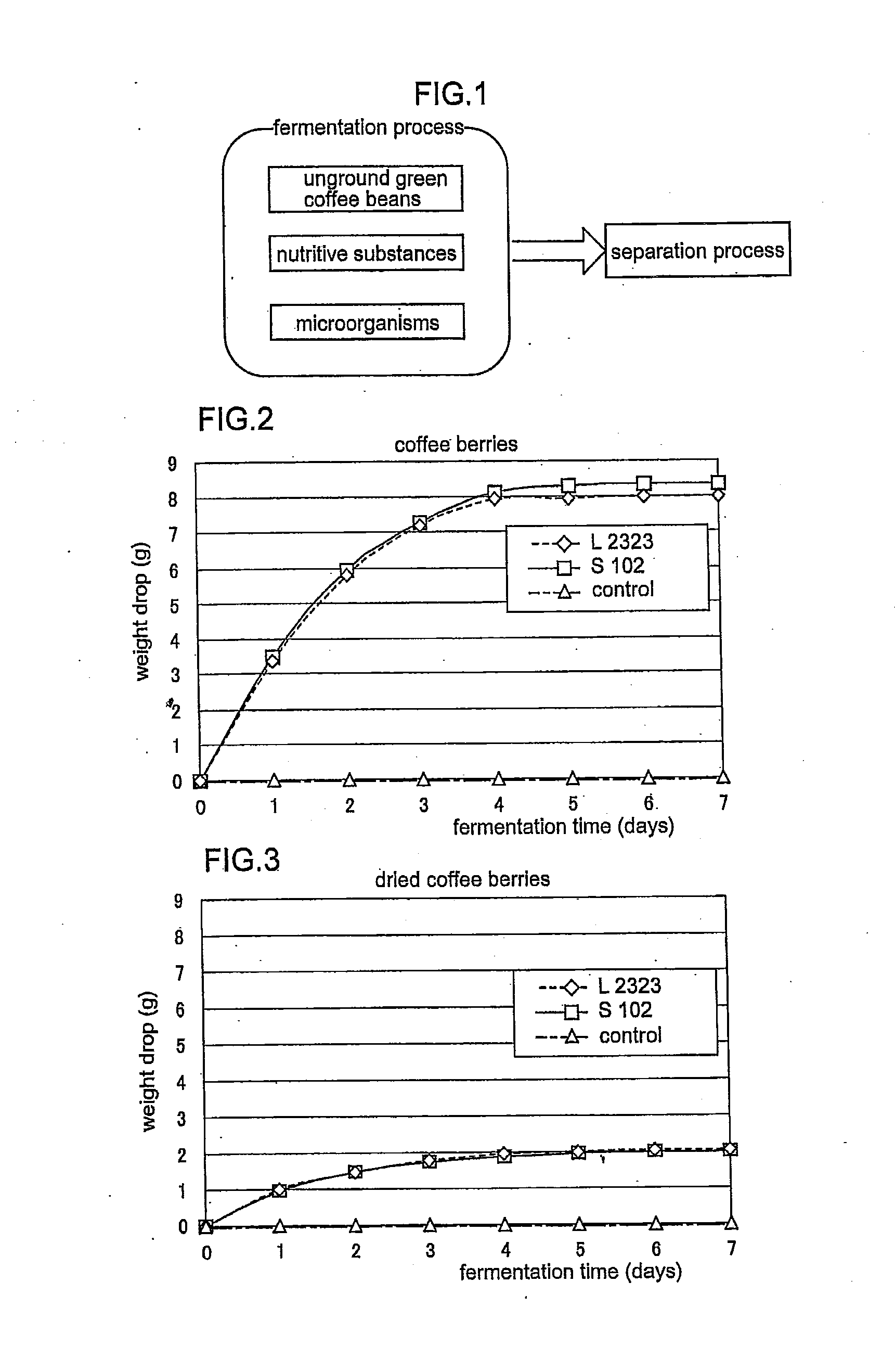

[0136]Using coffee berries and yeast, the form of the coffee berries and the yeast type were changed to assess the suitability of various conditions for fermentation.

[0137]Two types of coffee berries were examined, these being (1) undried coffee berries (Okinawa-grown Arabica berries washed in water), and (2) dried coffee berries that have been soaked in water (dried Brazil-grown Arabica coffee beans soaked in purified water for 40 minutes).

[0138]Two types of dried yeast (the L2323 and S102 described above) were used.

[0139]3 g of each dried yeast was suspended in 50 mL water heated to 41° C. and let stand for approximately 30 minutes, yielding a concentrated yeast-containing solution having a yeast concentration of 6.0×109 cells per 1 mL. This was then diluted by a factor of 20 to produce a yeast suspension (3.0×108 cells / ml).

[0140]100 g of each of the above coffee berries was placed in a triangular flask, and to this was added 250 mL of the yeast suspension, and the flask was cappe...

embodiment 2

[0146]Using dried coffee berries, the effect that microorganism fermentation has on the flavor and aroma of green coffee beans was examined.

[0147]Arabica beans grown in Brazil were used as the dried coffee berries. As the yeast suspension, the two types of yeast suspensions (L2323 and S102) described in Embodiment 1 were used.

[0148]500 mL yeast suspension was added to and absorbed by 200 g dried coffee berries. This was then placed in a triangular flask, and the flask was capped by a silicon cap and incubated for six days at 22° C.

[0149]The weight of the flask was measured after day six, and in both causes a drop in weight was confirmed (see Table 1). It was therefore concluded that fermentation by the microorganisms had occurred in each sample.

TABLE 1yeastweight drop (g)L23231.69S1022.09

[0150]

[0151]The coffee berries in the flask after six days incubation were dried at 55° C. for 24 hours in a drying machine, and then their pulp and skin were removed, producing 70 to 90 g of green ...

embodiment 3

[0171]An evaluation was performed on the roasted coffee beans obtained using green coffee beans that were processed by the method of processing green coffee beans according to the invention, and coffee beverages were obtained by grinding those roasted coffee beans, infusing them with water and then extracting the water through filtration using a filter. Evaluation of the coffee beverages was performed by preparing drip extract and canned coffee.

[0172]A. Evaluating the Roasted Coffee Beans

[0173]Roasted coffee beans were prepared using the three types of green coffee beans that were obtained in Embodiment 2 (L2323 green beans, S102 green beans, control green beans).

[0174]70 to 90 g of each green coffee bean was roasted for approximately 30 minutes at a temperature between 150 to 200° C. using a roasting machine (made by PROBAT; Battery Sample Roaster BRZ2), yielding approximately 40 to 50 g of roasted coffee beans with an L value (indicator of roasting) of about 20 (these will be refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com