Image forming apparatus, pattern position determining method, and image forming system

a technology of image forming apparatus and pattern position determination, which is applied in the direction of printing, other printing apparatus, etc., can solve the problems of difficult to accurately specify the edge difficult to reflect the spotlight, and difficult to detect the voltage of the light receiving element. to be stable, so as to achieve accurate specification of the position of the test pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0044]One feature of the present embodiment is performing an amplitude correction process which adjusts an amplitude relative to a detected voltage which is detected by a light receiving element.

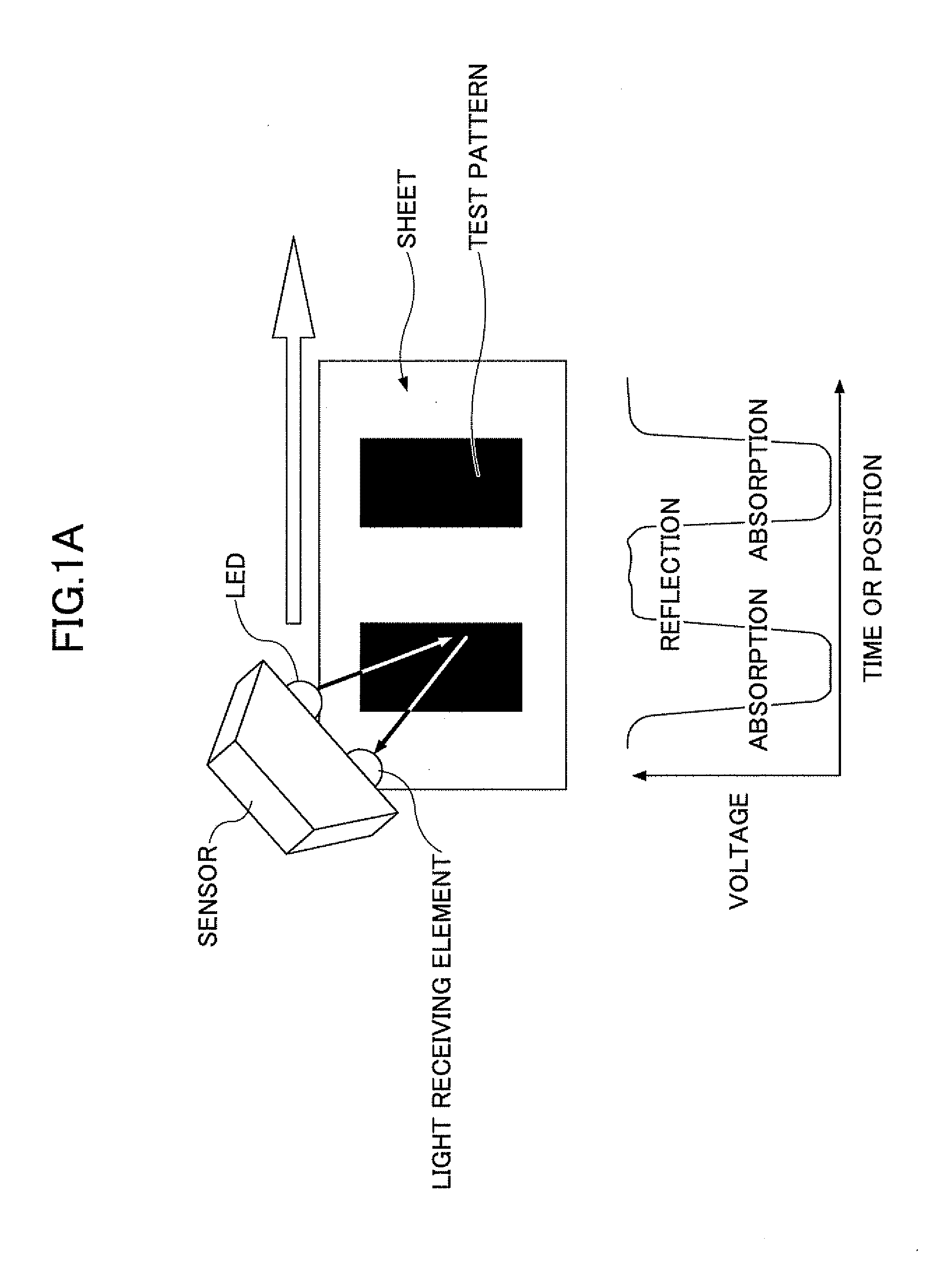

[0045]FIGS. 2A and 2B are exemplary diagrams which schematically illustrate a light emitting element, a light receiving element, and a sheet material. FIG. 2C shows an example of a detected voltage Vs2 of a sheet material with a low reflectance, such as a tracing paper, etc., while FIG. 2D shows an example of a detected voltage Vs1 of a tracing paper on which a test pattern is formed. As shown in FIG. 2C, when a spotlight scans a sheet material with a low reflectance (a high transmittance) as shown in FIG. 2C, the detected voltage becomes unstable. Moreover, when the spotlight scans the sheet material on which the test pattern is formed, the detected voltage is unstable even though the instablity is not likely to be noticeable due to an occurrence of a local maximum value and a local minimum...

embodiment 2

[0244]In the present embodiment, an amplitude correction process is described for an image forming system embodied by a server, not an image forming apparatus.

[0245]FIG. 25 is an exemplary diagram which schematically describes an image forming system 500 which has an image forming apparatus 100 and a server 200. In FIG. 25, the same letters are given to the same elements as FIG. 3, so that a repeated explanation is omitted. The image forming apparatus 100 and the server 200 are connected via a network 201, which includes an in-house LAN; a WAN which connects the LAN; or the Internet, or a combination thereof.

[0246]In the image forming system 500 as in FIG. 25, the image forming apparatus 100 forms a test pattern and scans the test pattern by a print position offset sensor, and the server 200 calculates the correction value of the liquid droplet ejection timing. Therefore, a processing burden of the image forming apparatus 100 may be reduced and functions of calculating a correction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com