Seal system for cooling fluid flow through a rotor assembly in a gas turbine engine

a gas turbine engine and cooling fluid technology, applied in the field of turbine engines, can solve the problems of pressure loss and restrict and achieve the effect of enhancing the flow of cooling fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

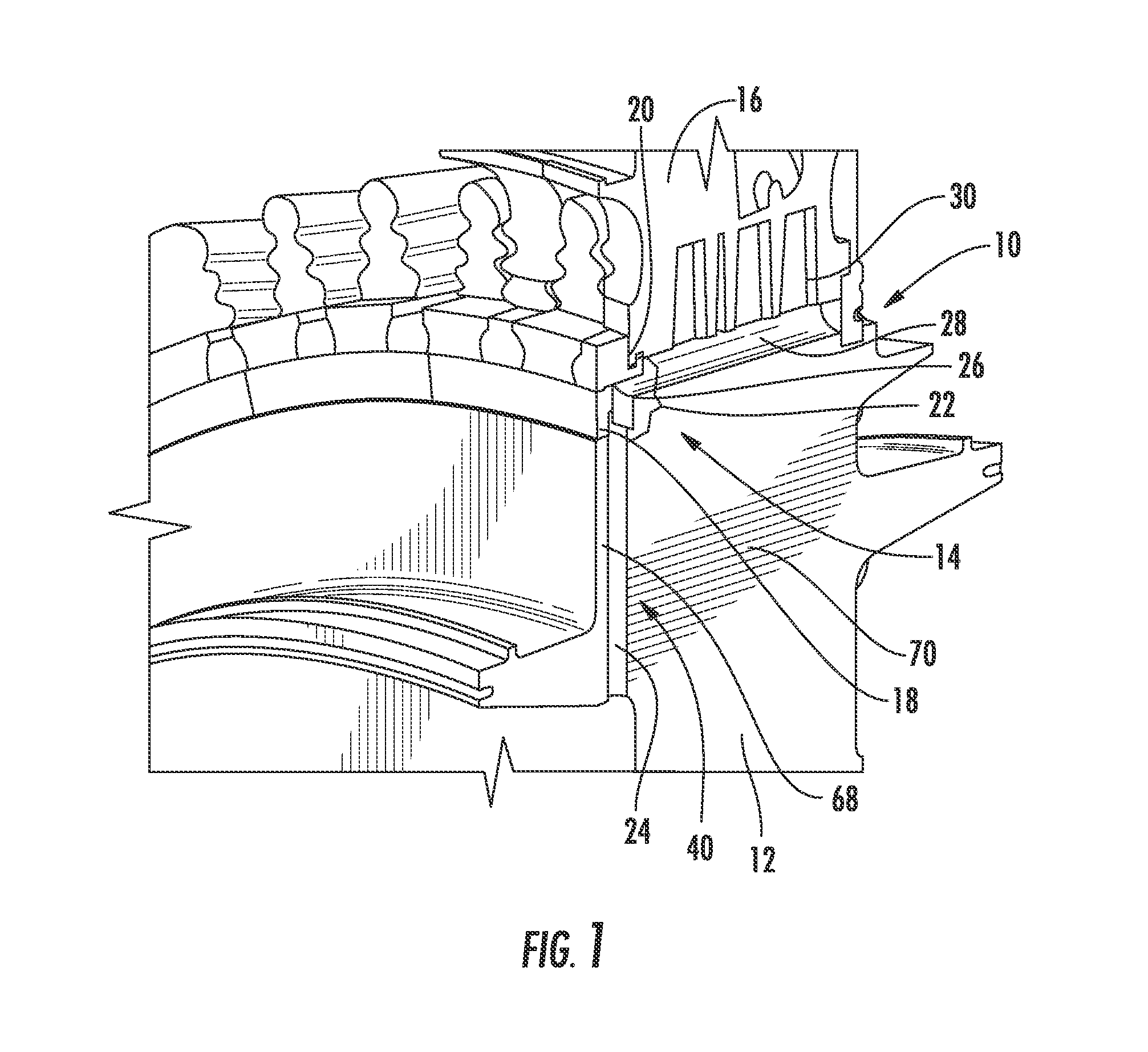

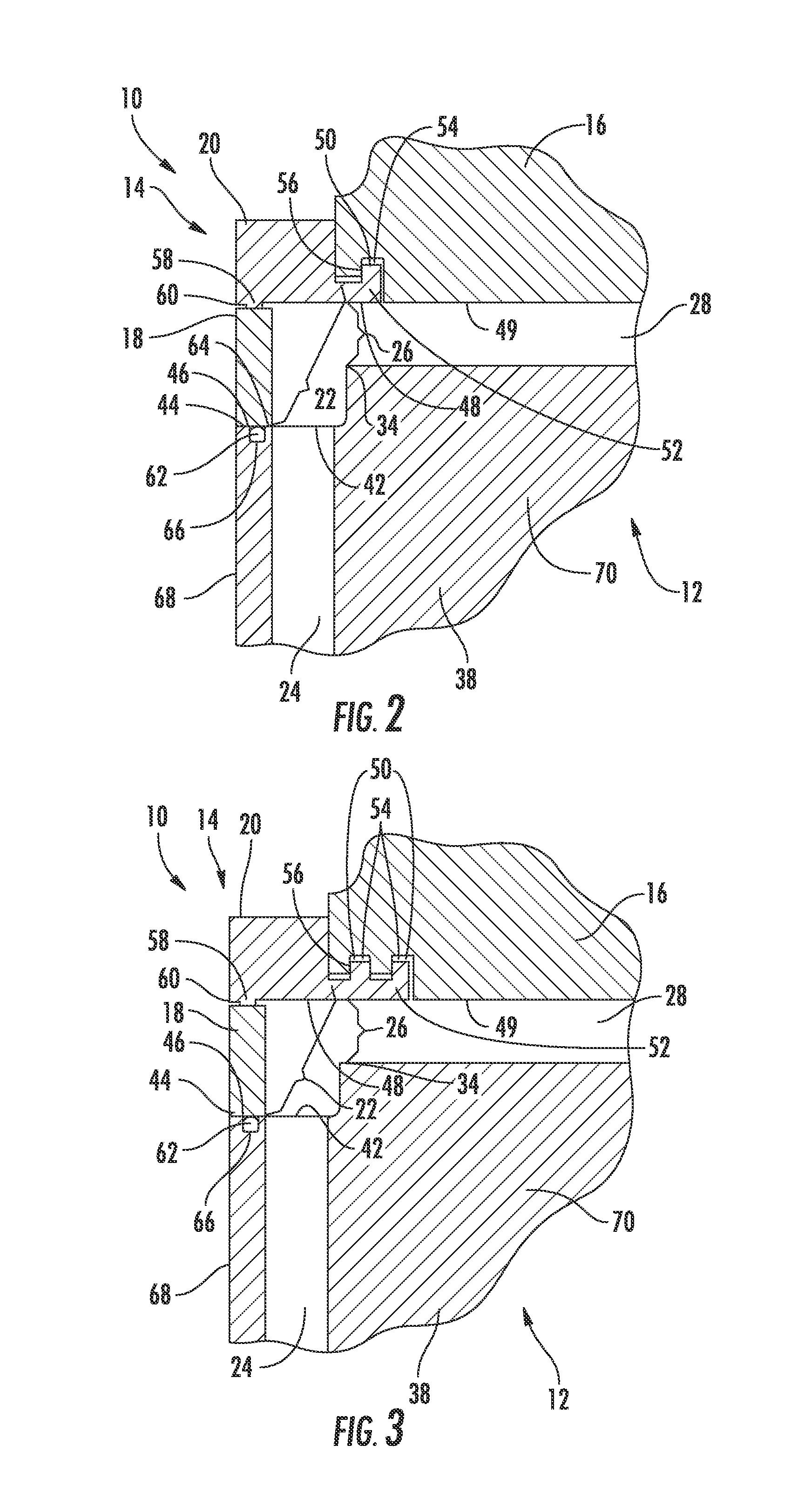

[0023]As shown in FIGS. 1-5, this invention is directed to a sealing system 10 for a rotor assembly 12 in a gas turbine engine that enhances the flow of cooling fluids from a rotor assembly 12 to turbine blades 16. The sealing system 10 may include a seal 14 configured to seal a conduit directing cooling fluids from a cooling fluid source into turbine blades 16 attached to the rotor assembly 12. In one embodiment, the seal 14 may be formed from a side block 18 and an upper seal 20 that seal a gap 22 between a radially outward extending first rotor supply channel 24 in the rotor assembly 12 terminating at an inlet 26 of an axially extending second rotor supply channel 28 that is in fluid communication with an internal blade cooling system 30 of a turbine blade 16. The seal 14 may include components that enhance the flow of cooling fluids over conventional configurations. In another embodiment, the sealing system 10 may include an integrated sealing block 32 configured to seal the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com