Hinge Pivot Mount Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

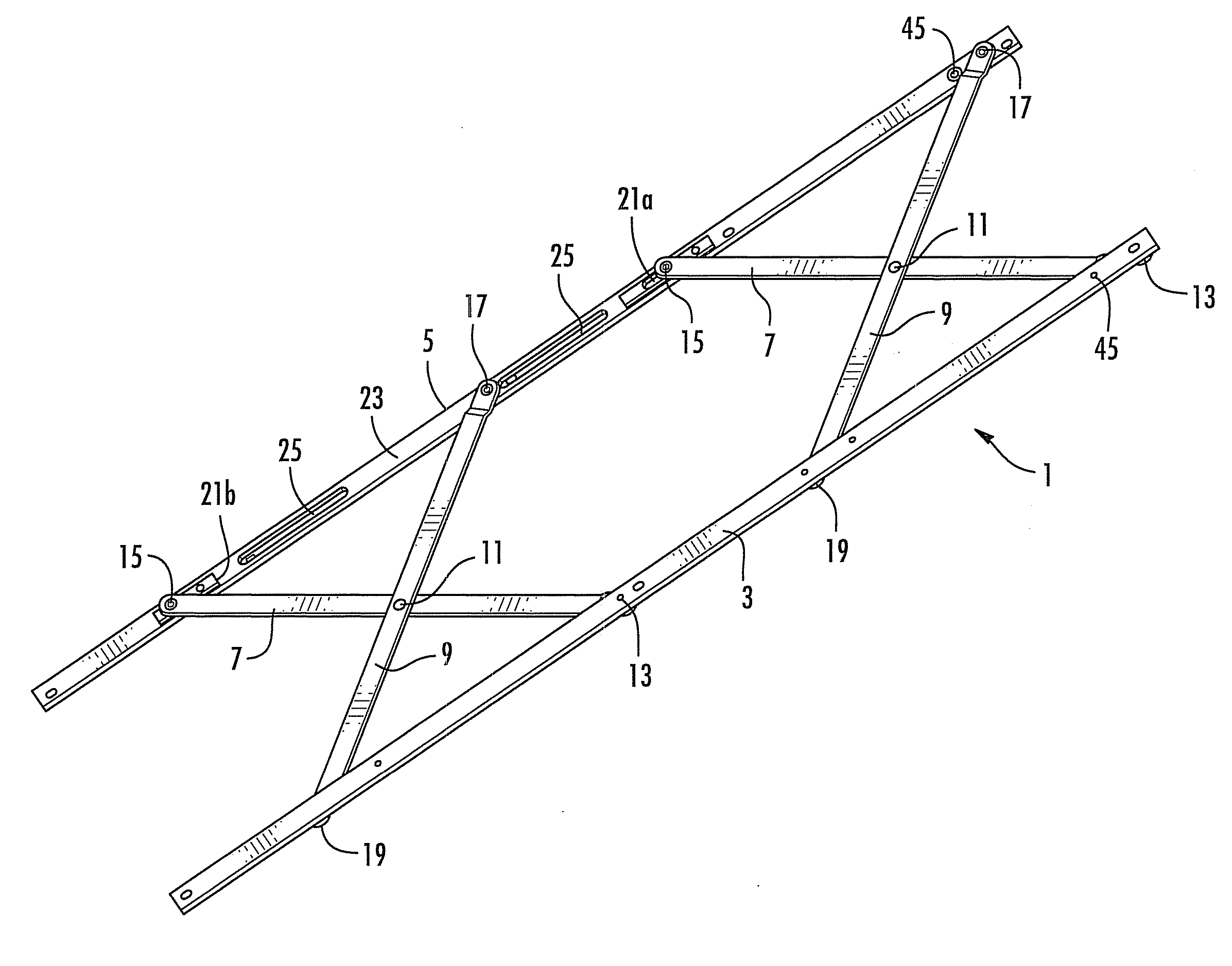

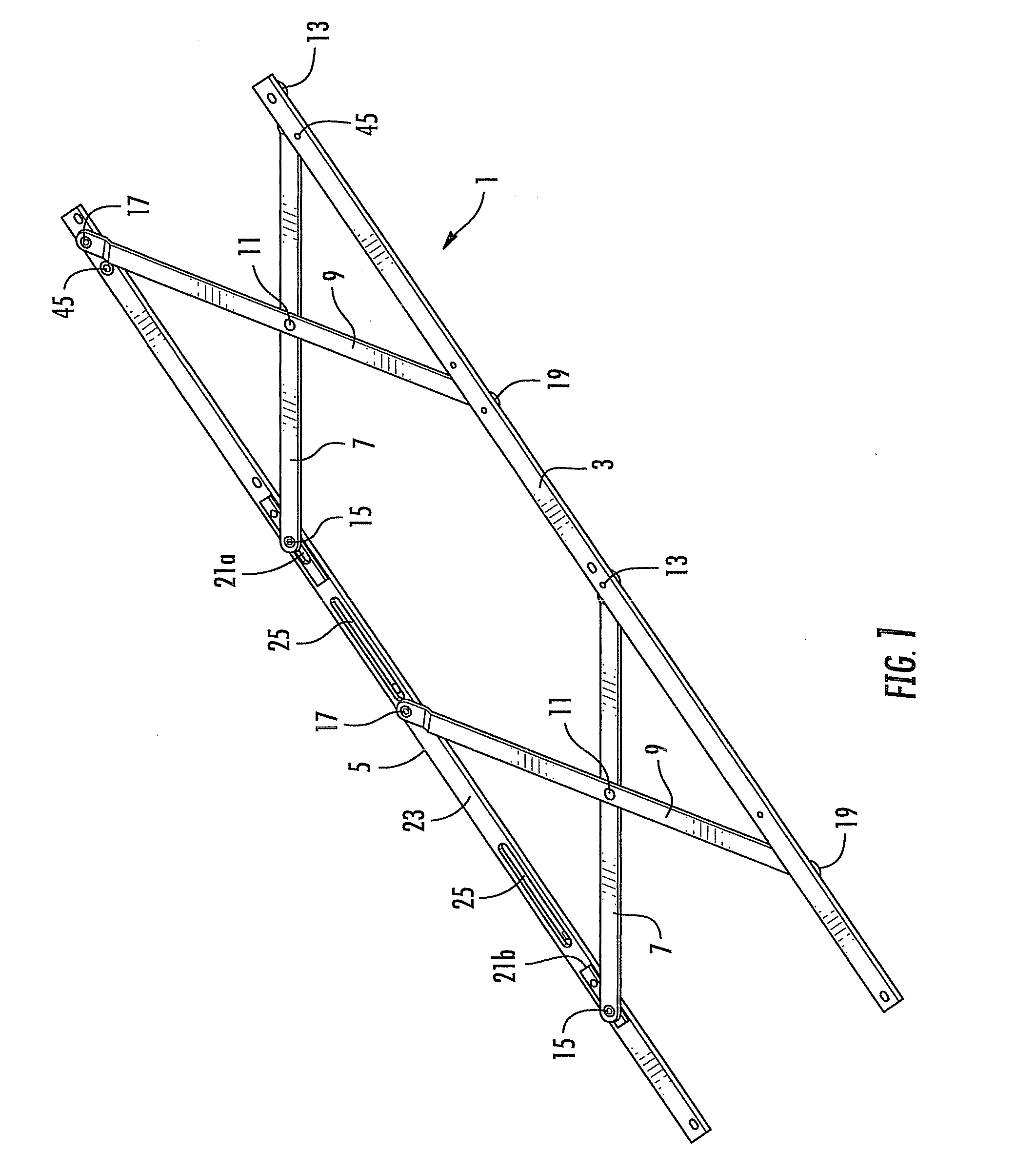

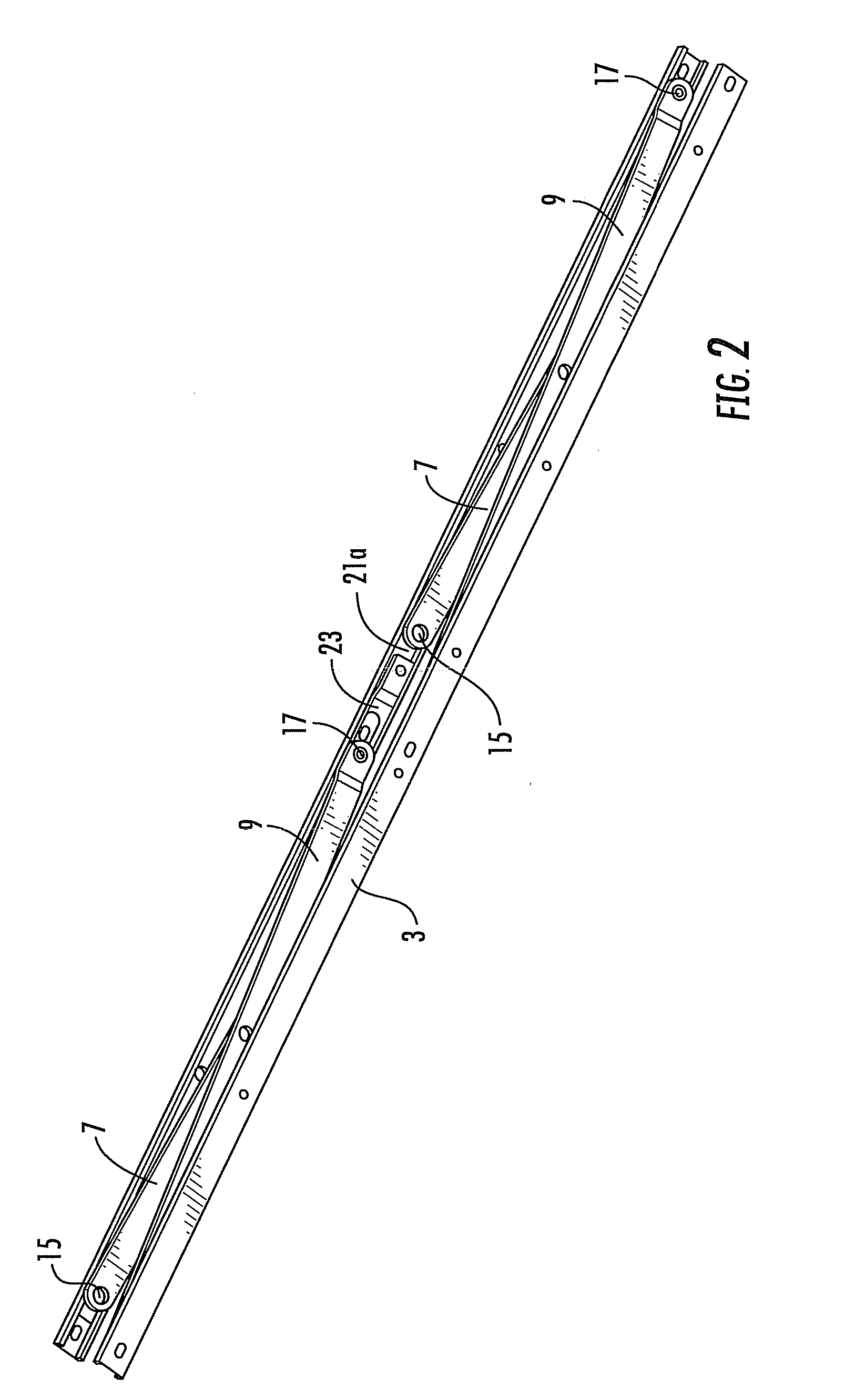

[0038]With reference to FIGS. 1 and 2 of the accompanying drawings, a parallel opening hinge system 1 is shown. As will be seen, the hinge system effectively incorporates two parallel hinge arrangements in a single product. The new parallel hinge includes a pair of parallel tracks 3, 5 each having essentially a C-shaped cross-section with a base and two side walls having inwardly facing flanges substantially parallel to the base. The hinge 1 further includes two pairs of crossing links 7, 9, wherein each pair of crossing links 7, 9 is pivotally connected at a pivot 11 and to each track 3, 5. The links 7 are attached to track 3 at fixed pivot points 13 and to track 5 at movable pivot points 15. Similarly, the links 9 are attached to track 5 at fixed pivot points 17 and to track 3 at movable pivot points 19. Thus, as the parallel tracks 3, 5 are moved together or apart, the movable pivots 15, 19 travel along the tracks whereas the fixed pivots 13, 17 remain fixed.

[0039]As will be seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com