Vehicle lamp

A technology for lamps and vehicles, which is applied in the direction of headlights, road vehicles, vehicle parts, etc. It can solve the problems of torque transmission damage, loose driving rod, and reduced operability of light adjustment, so as to prevent wear, improve reliability, and improve operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention will be described below with reference to the drawings.

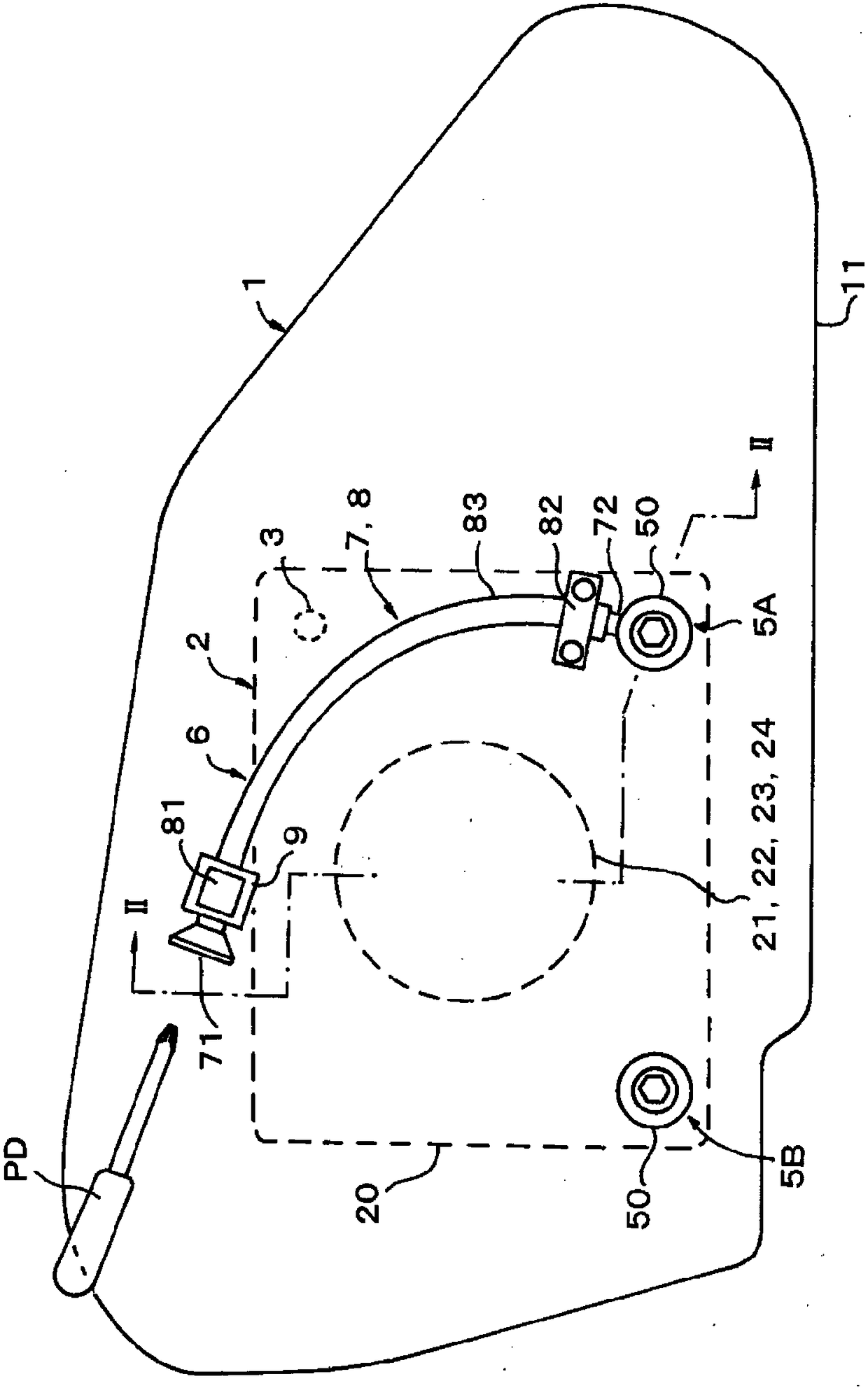

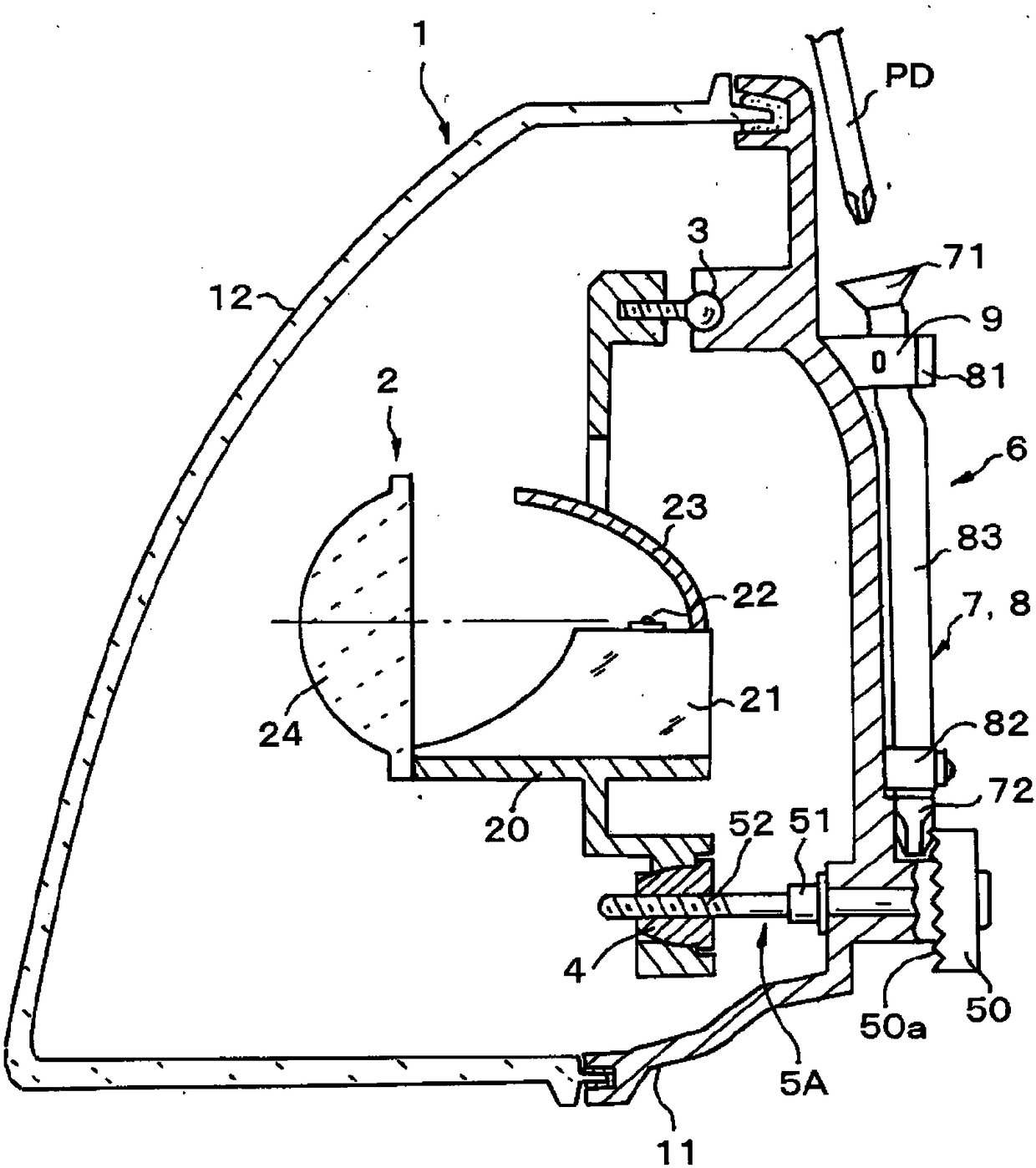

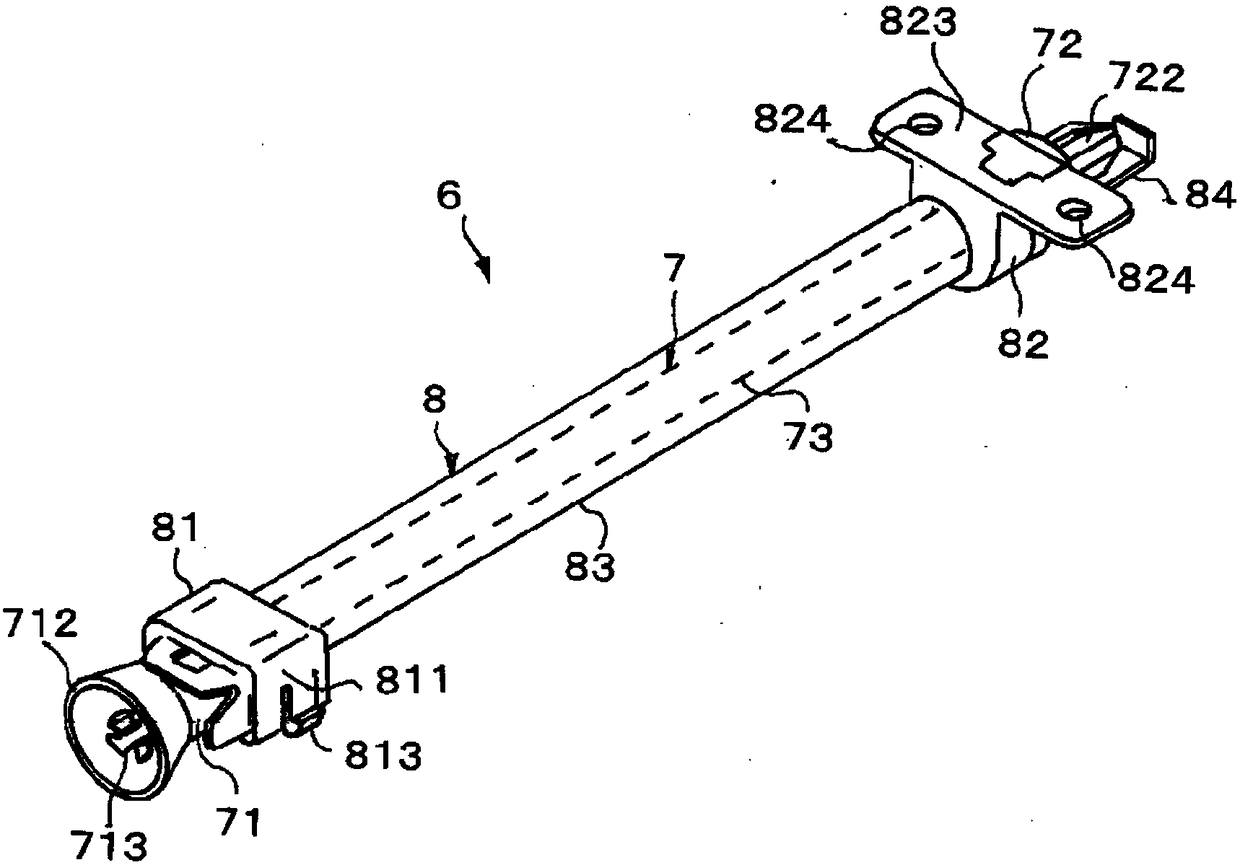

[0054] figure 1 It is the rear view of the left headlight of the automobile to which the present invention is applied, figure 2 is along figure 1 The enlarged cross-sectional view of the II-II line. Such as figure 2 As shown, the lamp housing 1 is constituted by a resin lamp body 11 and a translucent resin front cover 12 attached to cover the front surface of the lamp body 11 , and the lamp unit 2 is housed in the lamp housing 1 .

[0055] The lamp unit 2 is configured as a projection type lamp unit, and includes a base body 21, a light source 22 such as an LED (light emitting diode) mounted on the base body 21, a reflector 23 fixed to the base body 21 covering the upper area of the light source 22, and The projection lens 24 is fixed to the base 21 at a position in front of the light source 22 . The light emitted from the light source 22 is reflected by the reflector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com