Voice coil motors and magnetic circuits therefor

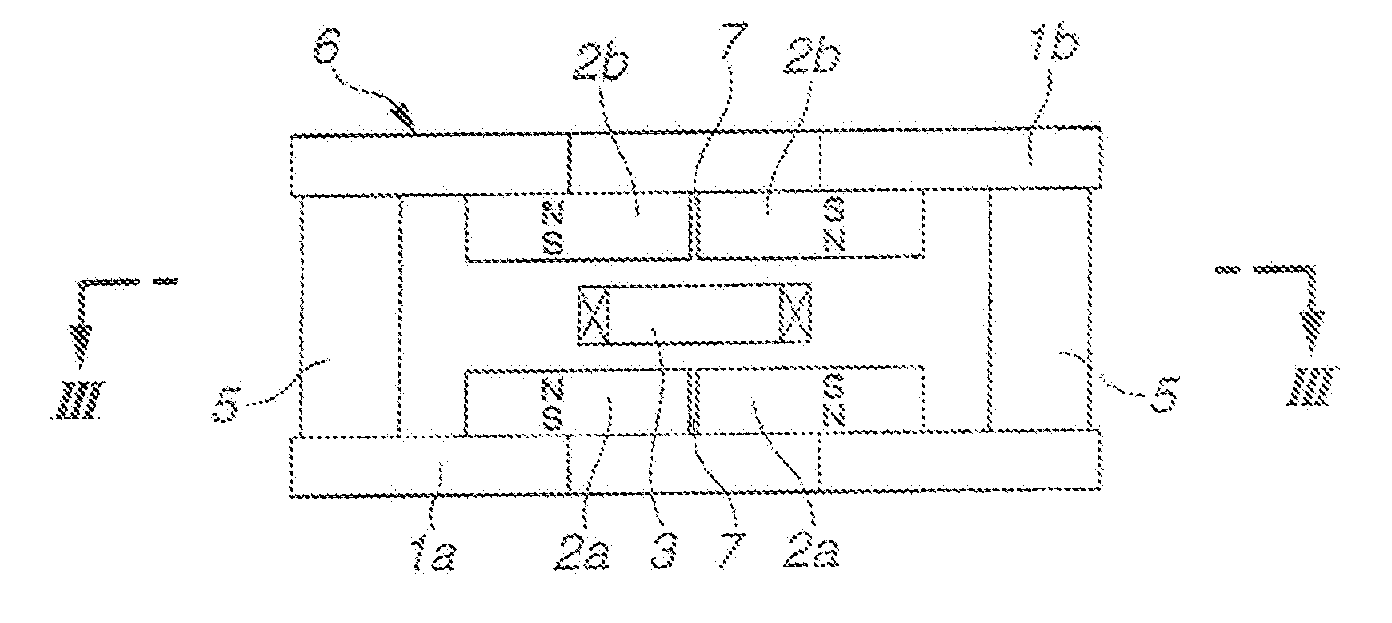

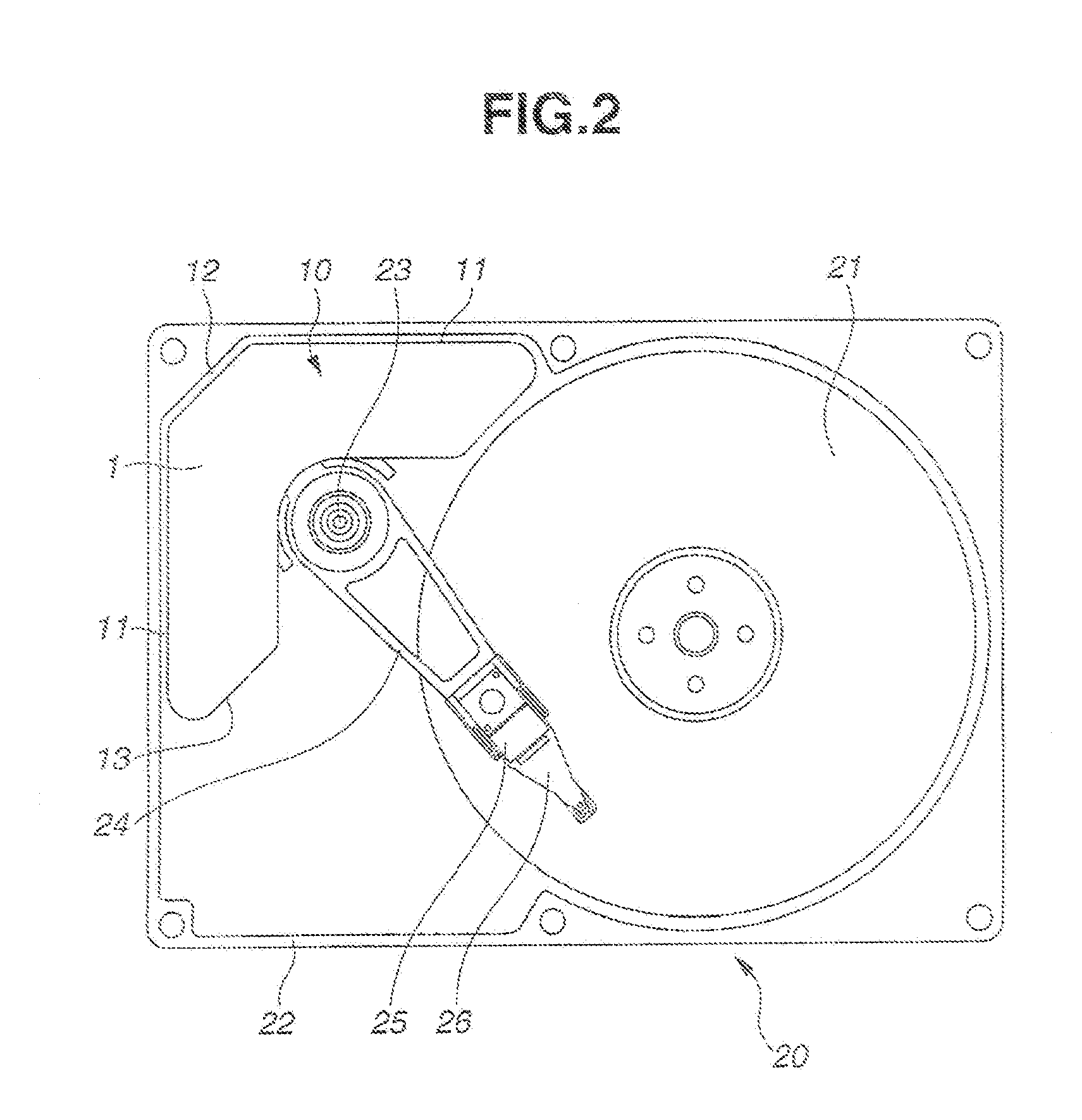

a voice coil motor and magnetic circuit technology, applied in the direction of magnetic circuit shape/form/construction, instruments, record information storage, etc., can solve the problems of difficult to secure the magnet to the yoke at the registered position, high cost and less production, etc., to achieve more accurate positioning of the magnetic head, reduce torque variation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0045]A Nd—Fe—B sintered magnetizable block (N48M by Shin-Etsu Chemical Co., Ltd.) was machined into a rectangular prism of 40.4 mm×12.4 mm×6 mm. It was adhesively attached to a yoke of carbon steel having a thickness of 5 mm and then magnetized to produce N and S poles by means of a magnetizer, constructing a magnetic circuit. The magnet could be attached to the yoke at its center, ensuring ease of registration.

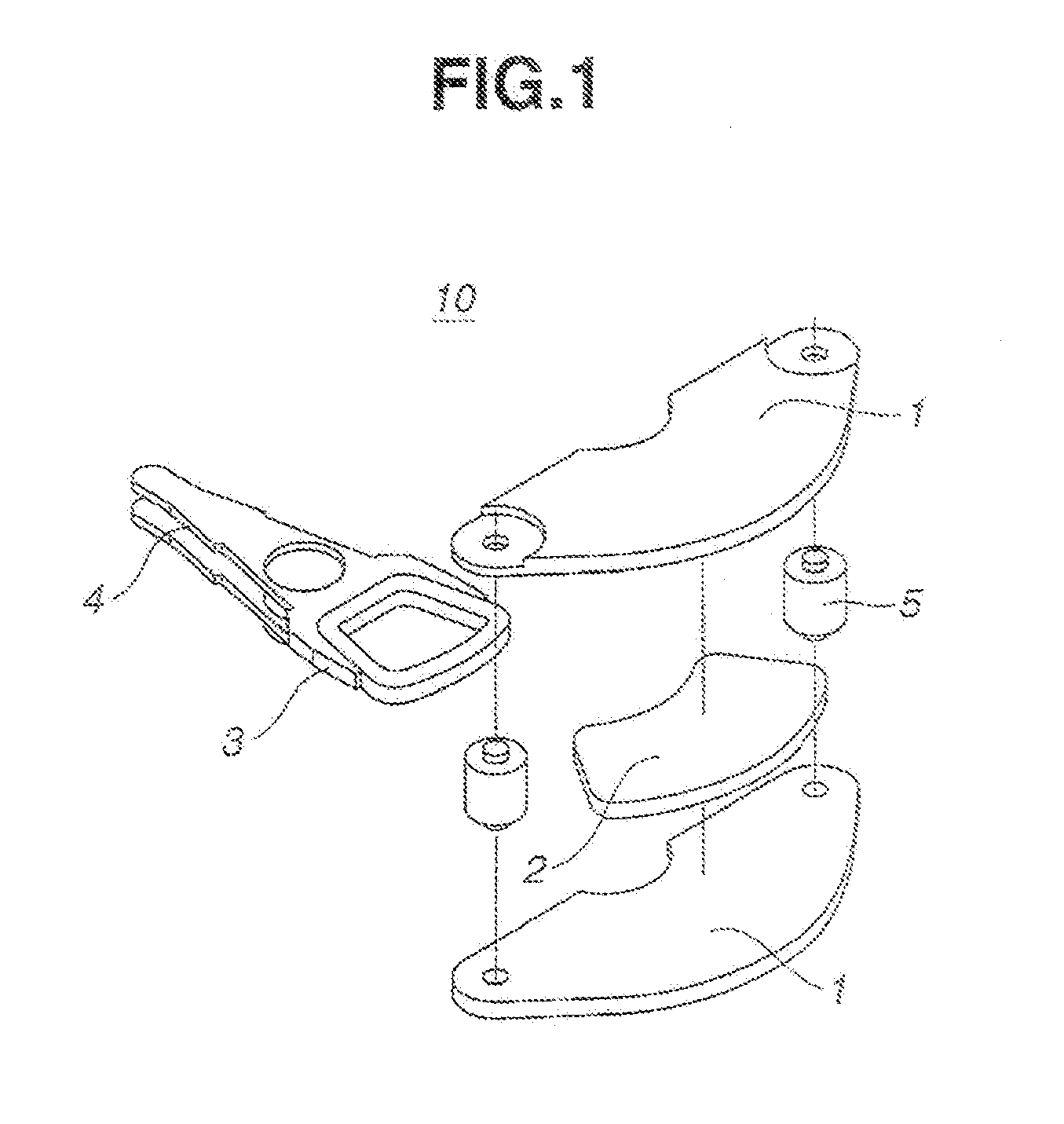

[0046]Two yokes were fixedly coupled by posts of the same magnetic material as the yokes to define a space of 10 mm between the magnets. An arm having a moving coil of copper wire wound thereon was inserted into the space, constructing a VCM as shown in FIGS. 4A and 4B. The torque of VCM was measured with the results shown in FIG. 11.

example 2

[0047]A Nd—Fe—B sintered magnetizable block (N48M by Shin-Etsu Chemical Co., Ltd.) was machined into rectangular prisms of 20.2 mm×12.4 mm×6 mm. Two pieces were arranged in a straight serial contiguous array and adhesively attached to a yoke of carbon steel having a thickness of 5 mm. They were magnetized in a thickness direction by means of a magnetizer so that N and S poles of serially arranged magnet pieces alternated along the yoke, completing a VCM as shown in FIGS. 5A and 5B. The assembly process was otherwise the same as in Example 1. The torque of VCM was measured with the results shown in FIG. 11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| rotational speed | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com