Instant beverage cartridges and methods

a beverage cartridge and cartridge technology, applied in the field of sealed cartridges, can solve the problems of occupying a reduced volume of instant beverage components, and achieve the effects of reducing waste, enhancing convenience, and reducing the time to prepare beverages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The following discussion is presented to enable a person skilled in the art to make and use one or more of the present embodiments. The general principles described herein may be applied to embodiments and applications other than those detailed below without departing from the spirit and scope of the disclosure. Indeed, the present embodiments are not intended to be limited to the particular embodiments shown, but are to be accorded the widest scope consistent with the principles and features disclosed or suggested herein.

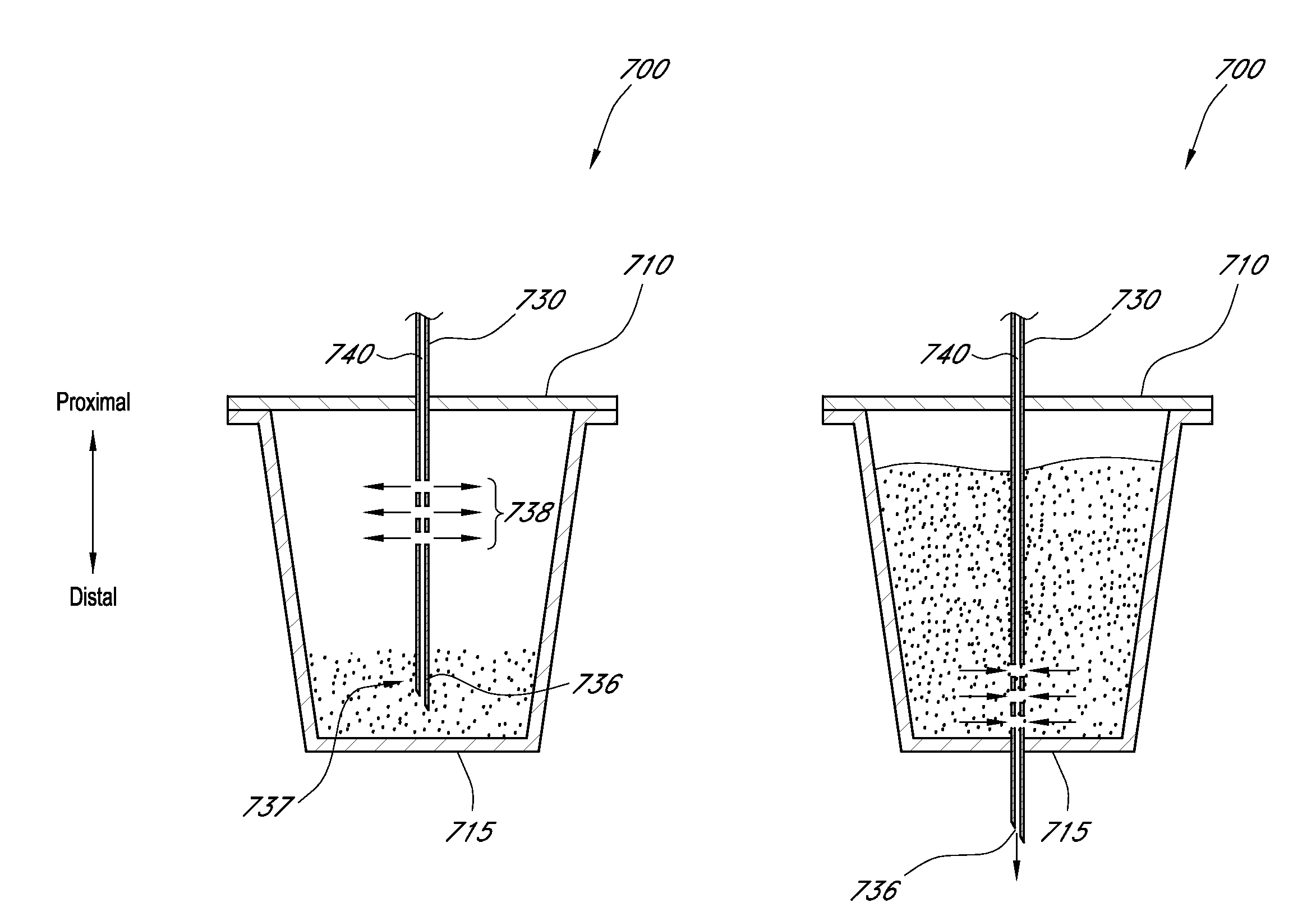

[0031]With regard to FIGS. 3A-3C, cross-sectional views of a single-serve beverage cartridge 300 for an instant beverage component 328, such as instant coffee, are illustrated. The single-serve beverage cartridge 300 can be configured for use in a single-serve beverage machine, such as an automatic single-serve coffee brewer. The term “cartridge” as used herein shall be given its ordinary and customary meaning, and shall include, without limitation, cartridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com