Staged biomass pyrolysis process and apparatus

a biomass pyrolysis and biomass technology, applied in the field of biomass pyrolysis, can solve problems such as undesirable, and achieve the effect of lowering the heating ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

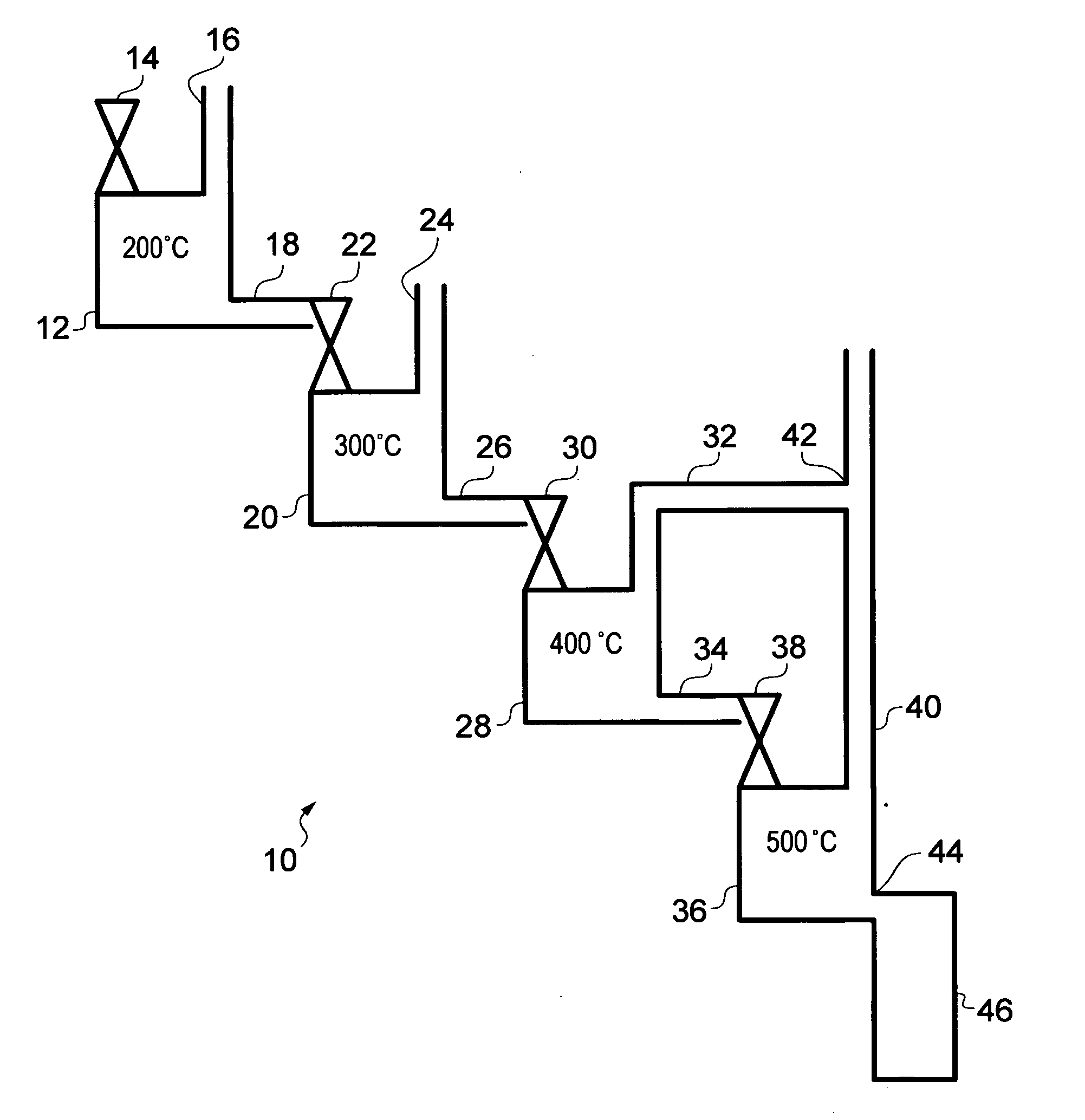

[0045]FIG. 1 shows the schematic layout of a pyrolysis reactor apparatus 10 according to one embodiment of the invention.

[0046]In this apparatus, there is provided a first heating stage with a first fluidized bed reactor 12 with heat carrier (not shown) heated to 200° C. This heating stage amounts to a first pre-pyrolysis heating stage. Biomass feed material (not shown) is fed into first fluidized bed reactor 12 via inlet 14. Gaseous products (i.e. products, gaseous at or near 200° C., of heating the biomass feed material at 200° C.) from the first fluidized bed reactor 12 are extracted at first reactor gas product outlet 16. The gas product of the first reactor may be water-rich, but may still have a useful heating value. In this case, the gas product of the first reactor may be used to heat the heat carrier used in one or more of the reactors.

[0047]At the base of the first reactor 12 is outlet 18, for conveying the processed biomass feed material from the first reactor 12 to a sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number length mean particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com