Anaconda-reaction, liquid-container/fuel-tank structure, and proective jacketing

a technology of liquid container and tank, applied in the direction of transportation and packaging, rigid containers, packaging, etc., can solve the problems of lack of anti-leak coating, failure to hold together, loss of life,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

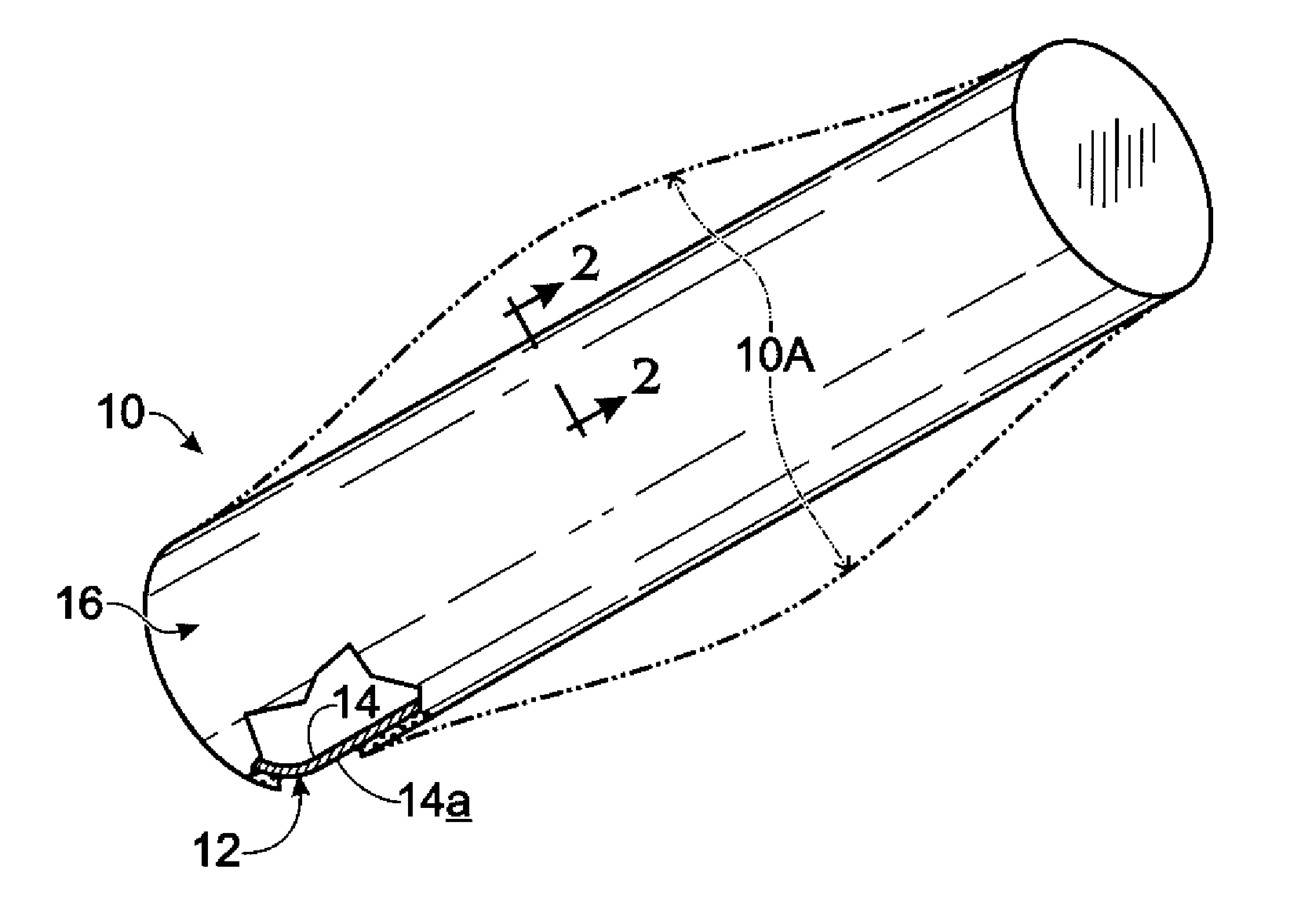

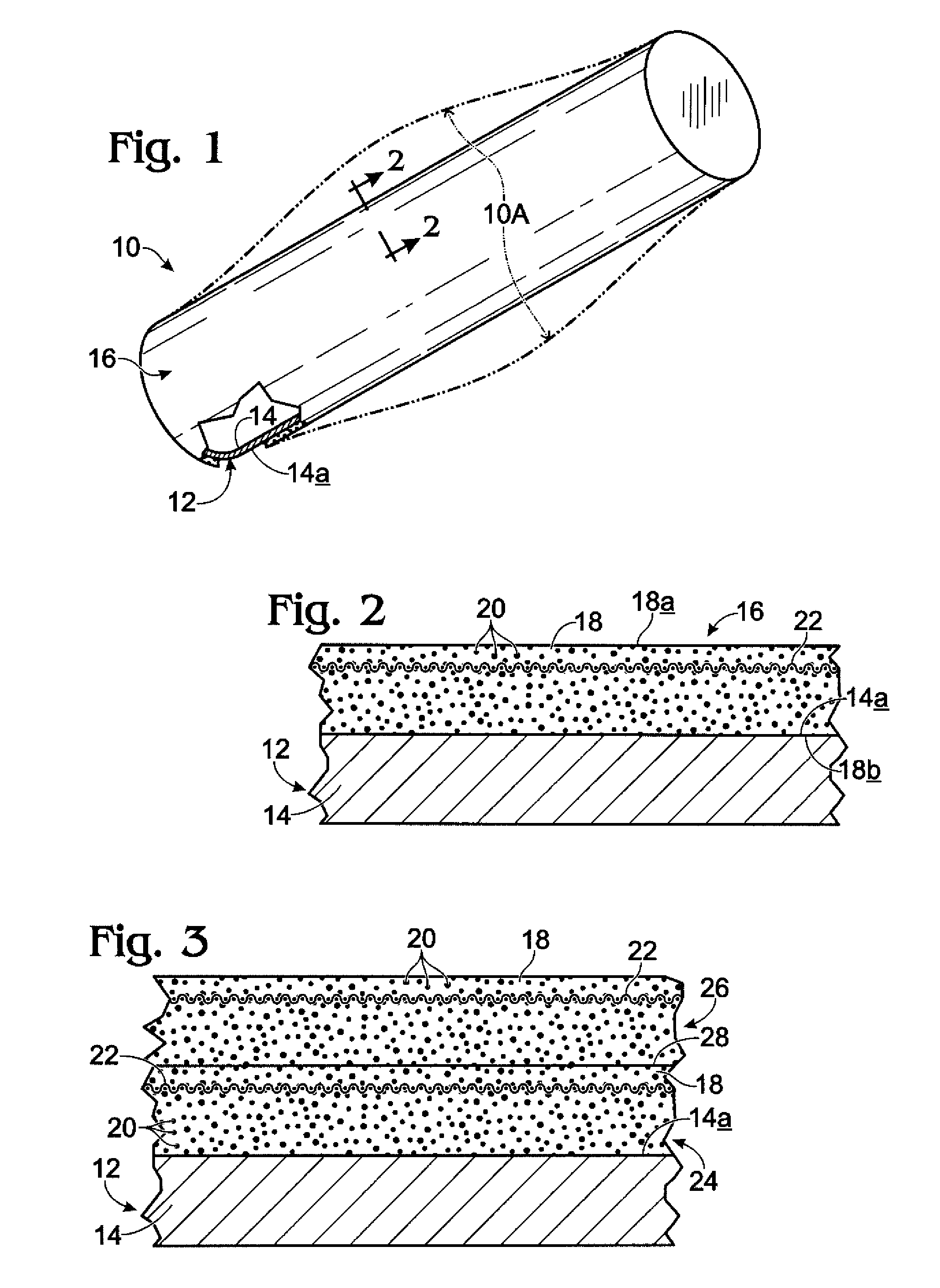

[0017]Turning attention now to the drawings, and referring first of all to FIGS. 1 and 2, indicated generally at 10 in FIG. 1 is a preferred and best-mode embodiment of an overall, anti-burst, anaconda-reaction liquid-container structure proposed by the present invention. More specifically, structure 10 includes, in the illustration of the invention now being given, an elongate, cylindrical, metallic, liquid-fuel container 12 having a barrier wall 14 with an outside surface (cylindrical and end) 14a which has been jacketed / coated / covered, as will shortly be explained, with an explosion / burst-containing, anaconda-reaction, single-layer jacket 16, also referred to as a jacketing structure, and as a coating, or coating structure. The term “single layer” regarding jacket 16 is employed as a convenient way to reflect the unitary nature of the three cooperative elements, shortly to be described, which collectively make up the jacket.

[0018]In solid lines in FIG. 1, structure 10 is shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com