Method and apparatus for single-trip wellbore treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

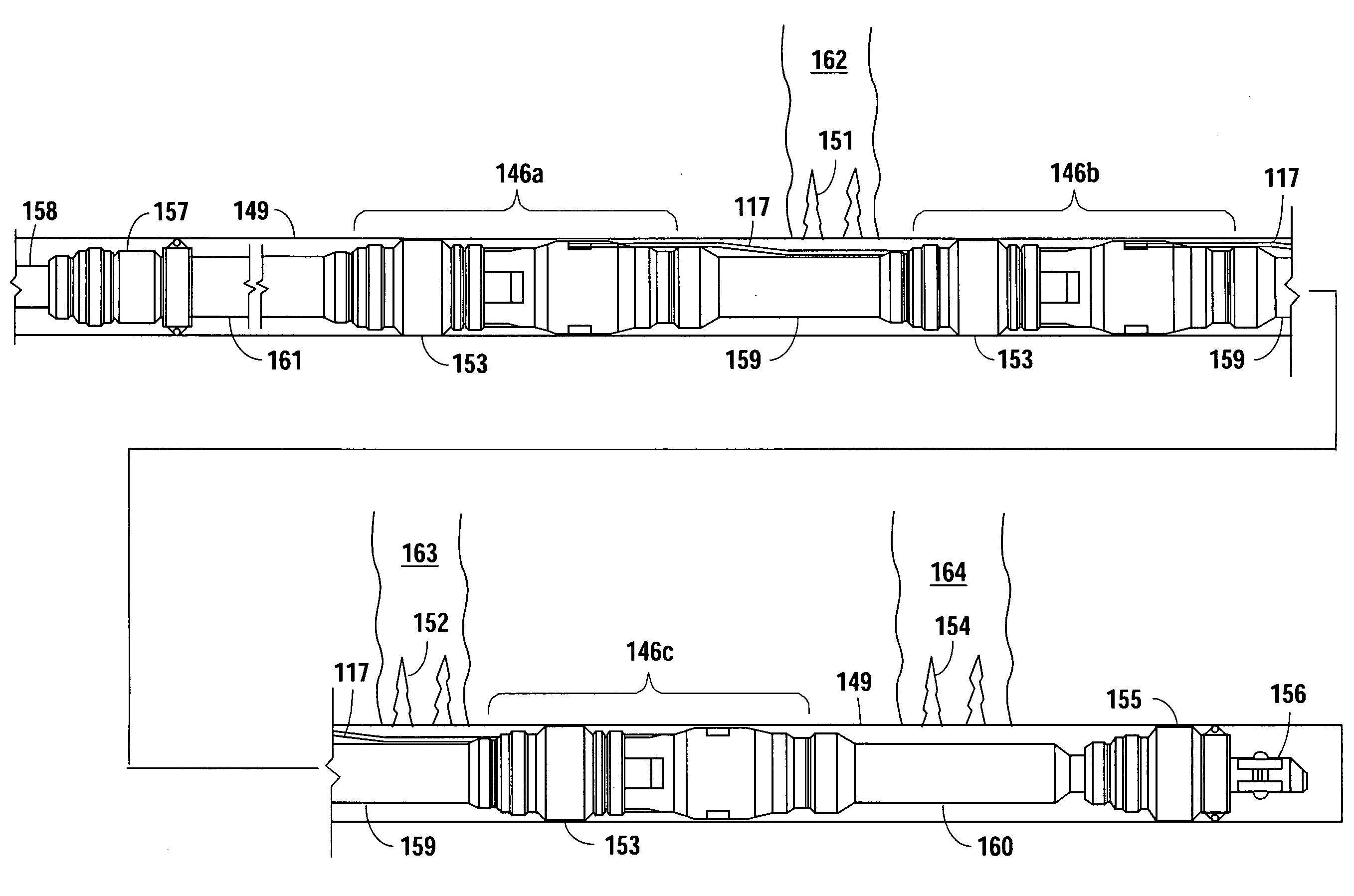

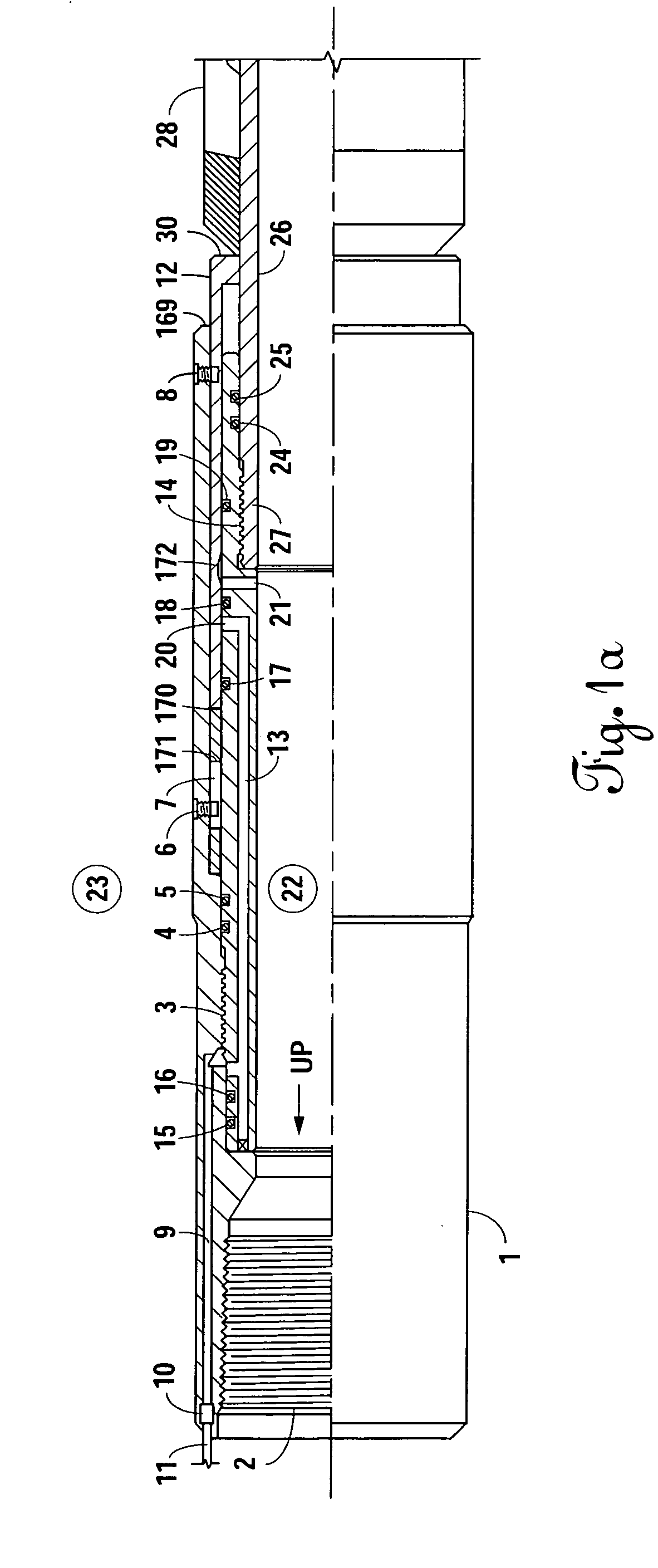

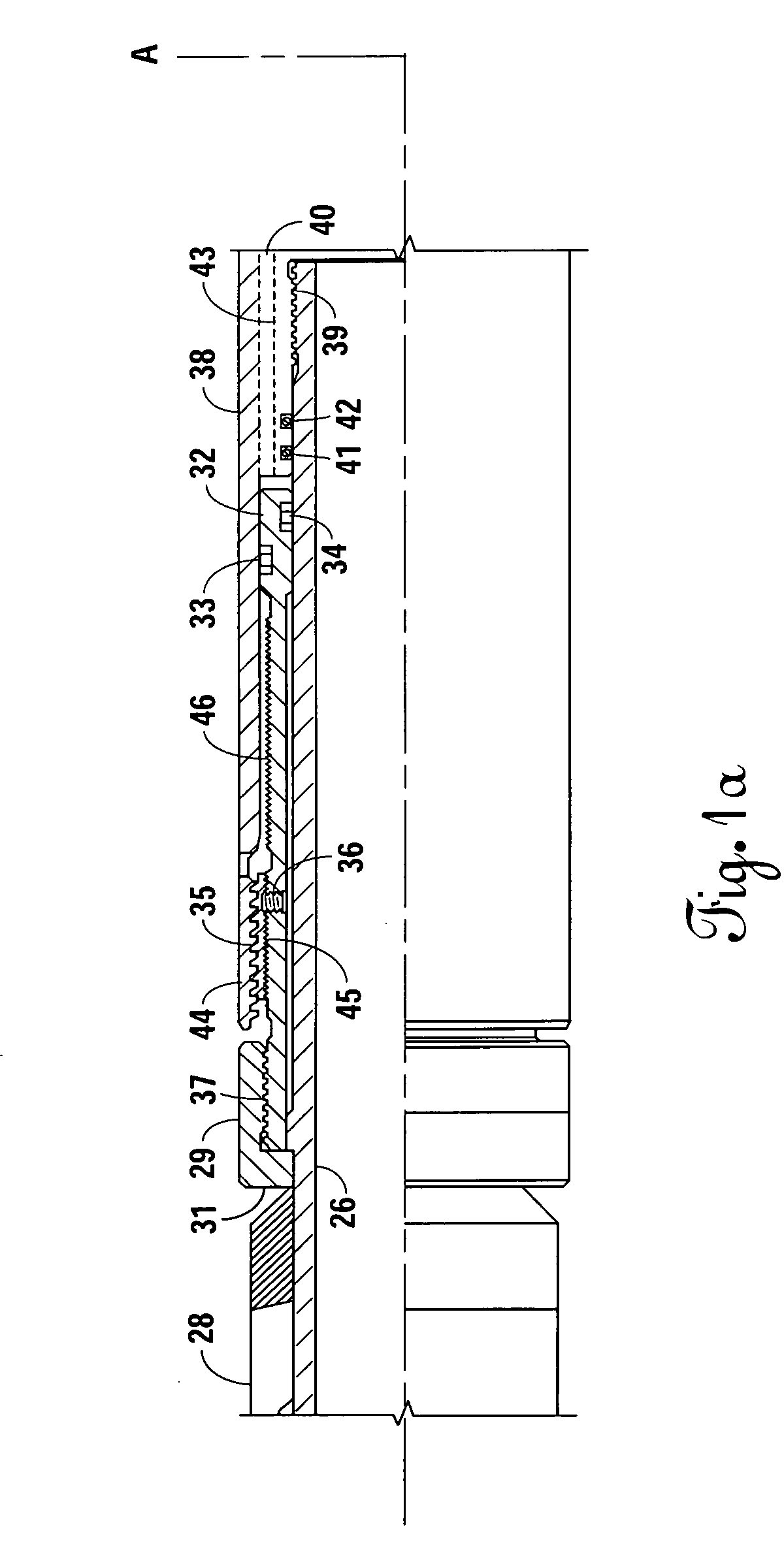

[0020]With reference to FIG. 1a, a schematic of the present invention shows a 90 degree lengthwise cross-section of the apparatus. This portion of the apparatus is the packer with only a packing element. A packer may be used that has a slip system added and a packer may be used that has a release devise added. Top sub 1 has a connecting thread at the top end 2, an internal thread 3, and o-ring seals 4 and 5. Shear Screws 6 shearably connect Top Sub 1 to Shear Ring 7. Shear Screws 8 shearably connect the Top Sub 1 to Push Sleeve 12. The hole 9 communicates with hole 13. A fitting 10 seals in hole 9 and also connects to hydraulic control line 11. Hole 13 is located inside of Flow Body 14. Seals 15, 16, 4, 5 seal between the Top Sub 1 and the Flow Body 14 to isolate flow paths 9 and 13 from pressure inside the tool 22 or outside the tool 23. Port 20 has Seals 17 and 18 to seal off Port 20 with Push Sleeve 12. Seals 18 and 19 with Push Sleeve 12 seal off port 21 to prevent pressure in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com