Heat pump defrost control

a heat pump and control technology, applied in the field of heat pumps, can solve the problems of reducing the efficiency of a heat pump and one of the more expensive repairs of the reverse valve, and achieve the effect of reducing the shock of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

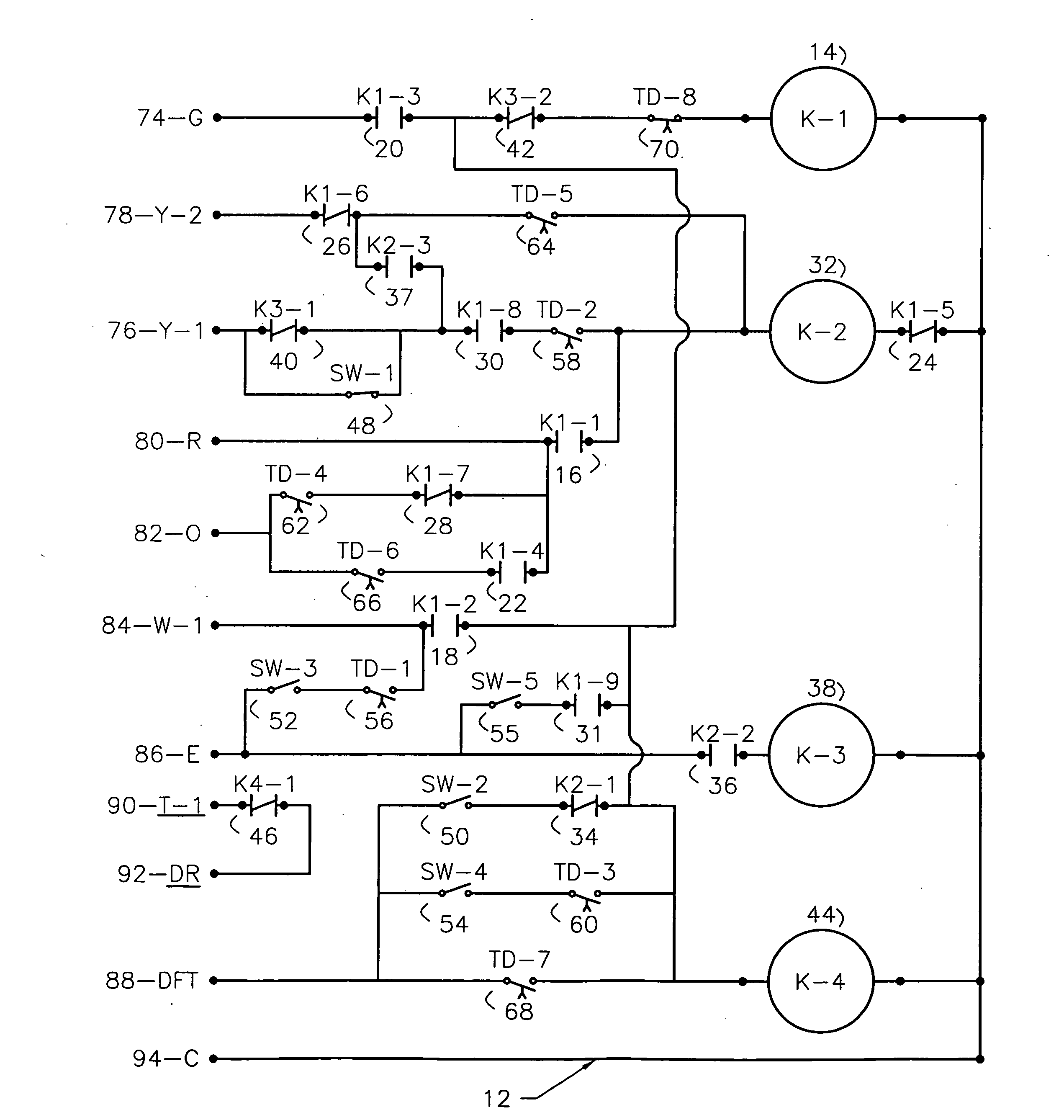

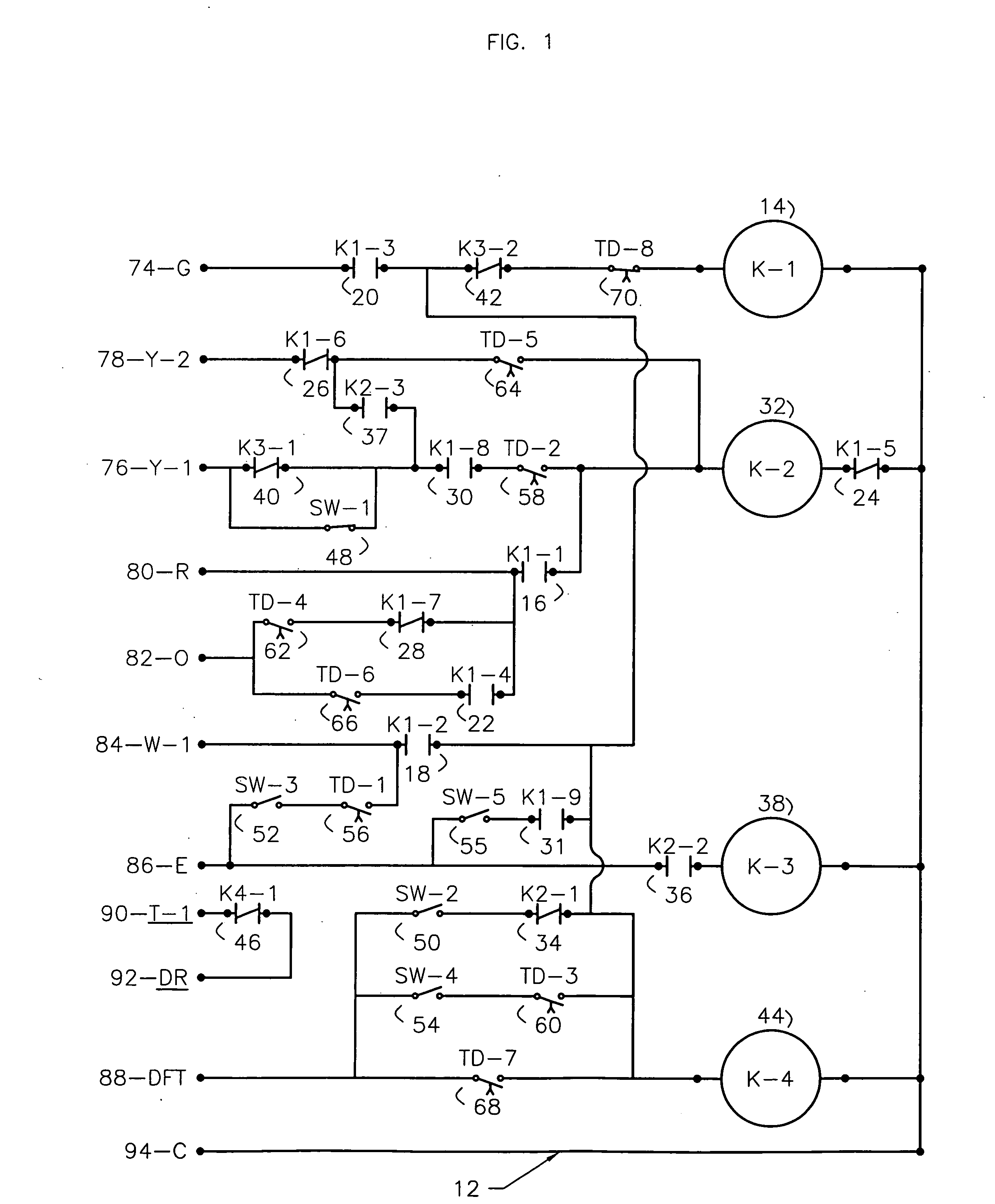

[0087]Referring to the drawing FIG. 1, a schematic diagram is shown front view of an off-cycle heat pump defrost control 12 embodying the present invention with circuits to be etched and parts mounted on a PCB to be installed in the junction box of a package or split unit (outdoor condenser) with connections 74 through 94 made

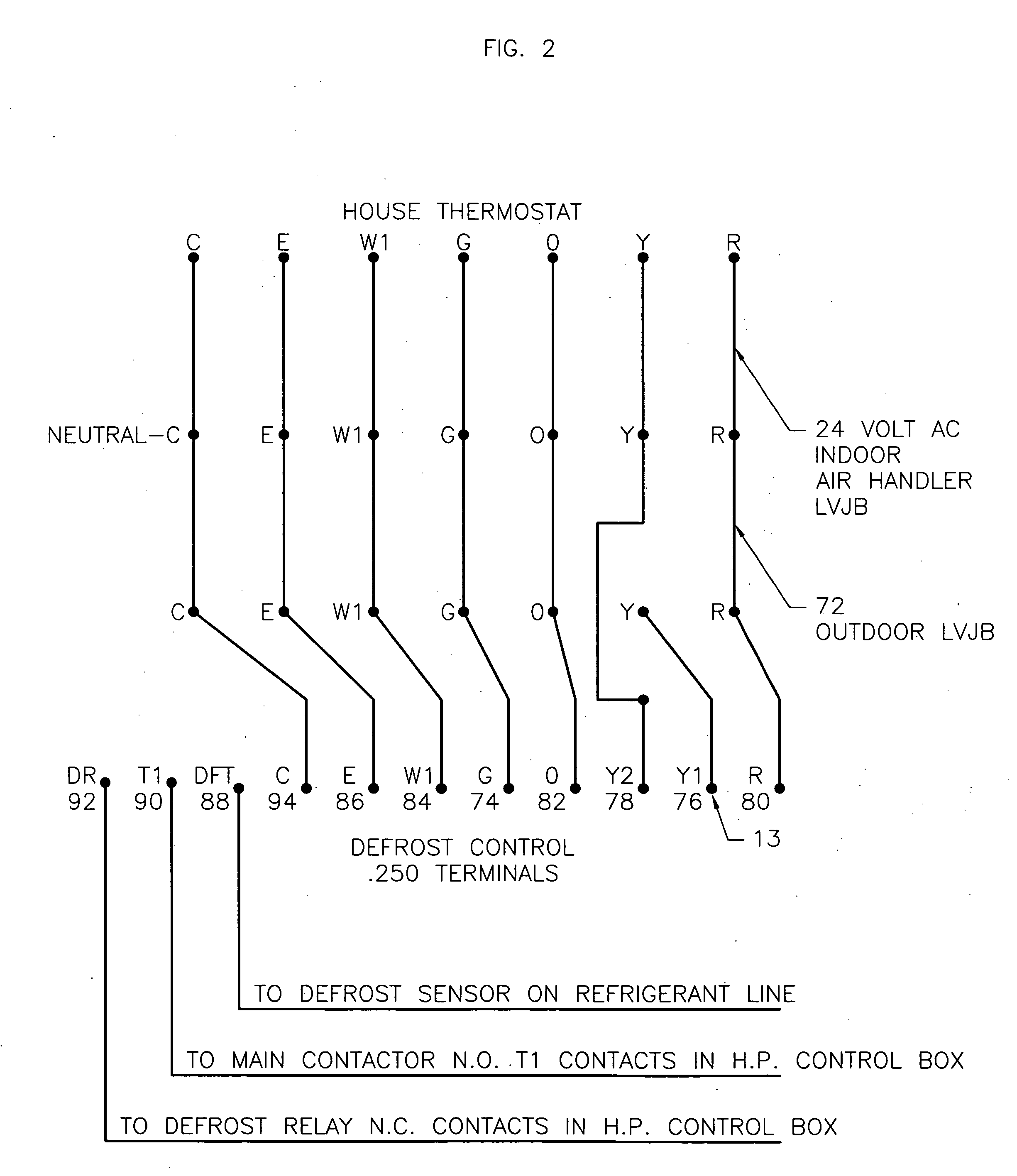

[0088]In reference to connection diagram 13FIG. 2 for split heat pump units, the defrost control board connections 13 are the same as the package units 12. The defrost board section 13 is the only relevant part to the present invention. 13 has the the same reference numbers as 12. The remainder of drawing 13 which includes the thermostat, air handler, and the outdoor low voltage junction box, is shown for Illustration purposes.

[0089]To further clarify the connections and the purpose of the circuits in FIGS. 1 and 2 referenced by identification numbers as follow:[0090]G-74—Controls blower motor paralleled with existing green conductor in LVJB 72.[0091]Y1-76—Conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com