Sweep gas for membrane-based dehydration modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

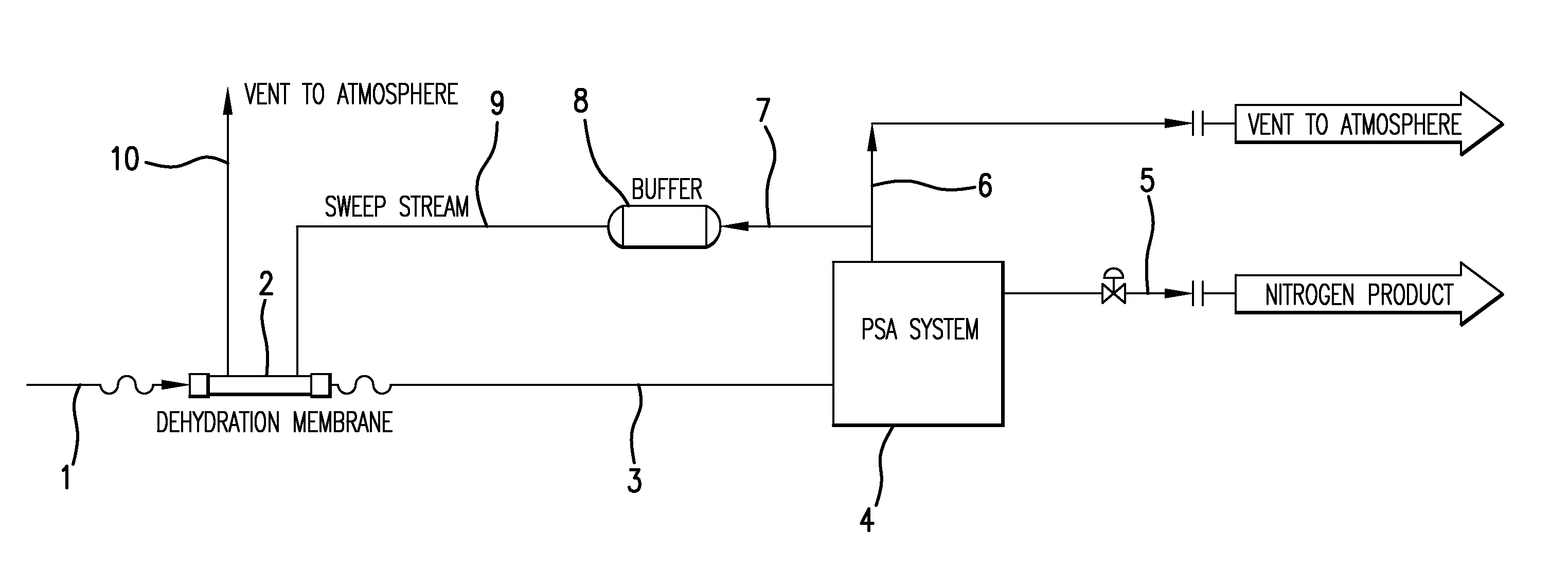

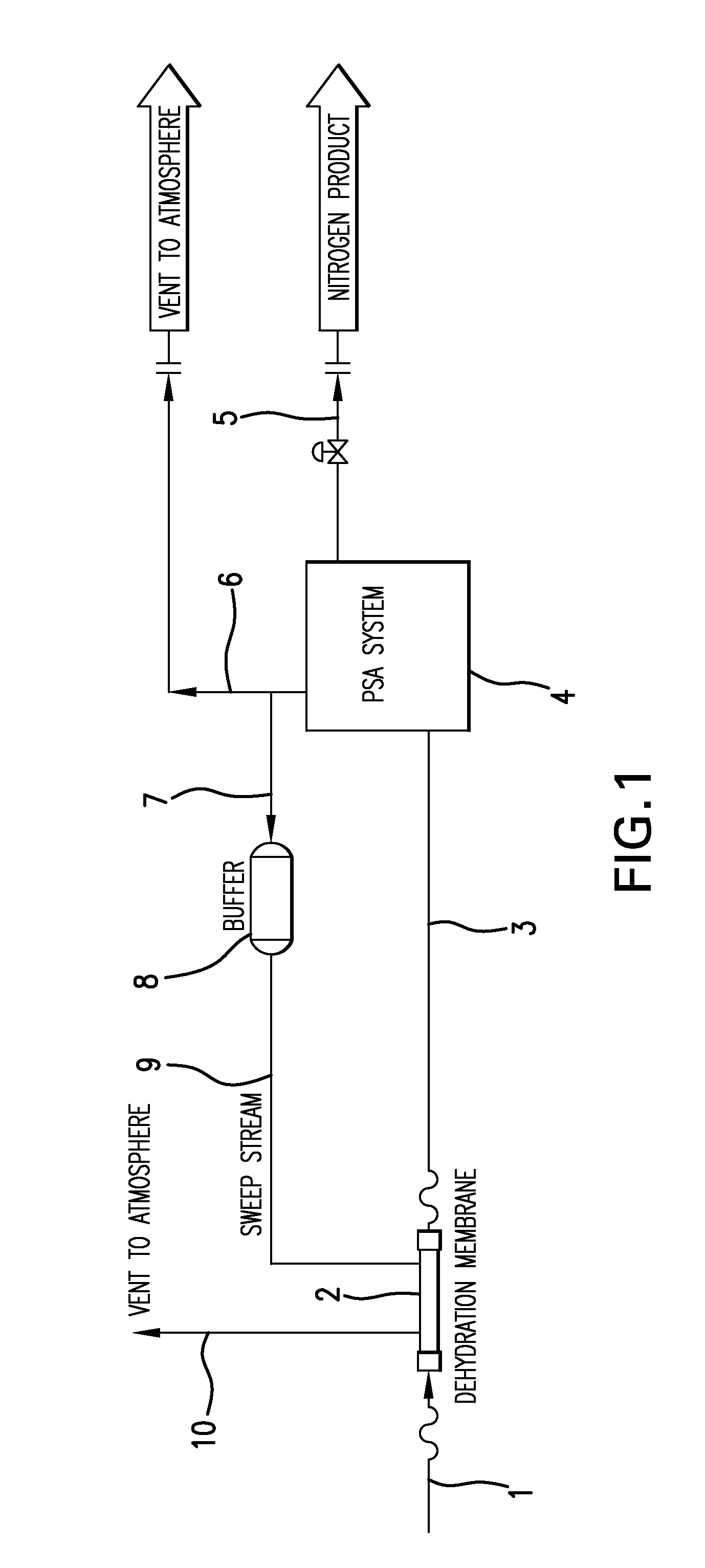

Image

Examples

example

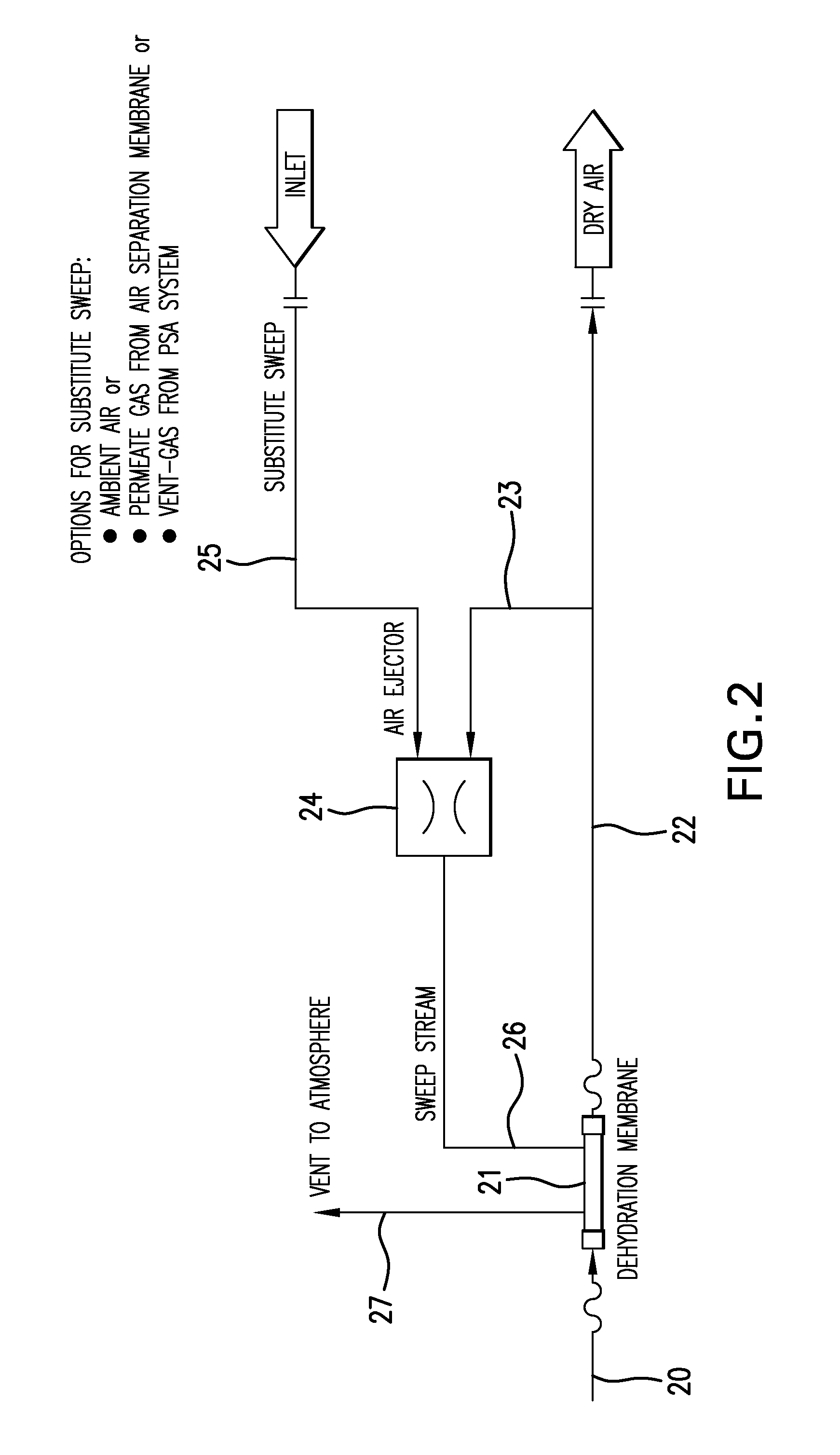

[0041]An air dehydration module, available commercially from Generon IGS, Inc., of Houston, Tex., having the model number 4100GMD-123, was operated using both a conventional product sweep stream and one in which an air ejector was used to make a combined product gas and ambient air sweep stream. At a target 43° F. pressure dew point (equivalent to a dew point of about 4° F. at atmospheric pressure), one uses 12% less vented compressed air for a given amount of net product air produced. Shown below are the results for a typical module operating at 100 psi.

Product TotalAmbientSweepCompressed AirAir inPermeation FlowRequirement forSweepModuleEjectorFlow(% ofPurge(% ofPressureUsed(% of feed)Feed)(% of Feed)Feed)DropNo2.95.58.407.38 psiYes3.14.27.31.76.61 psi

[0042]Thus, the use of the air ejector reduces the total compressed air requirement by about 13%. Therefore, the power cost is reduced by the same percentage. The module pressure drop was reduced by about 10%.

[0043]The above results ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Pressure drop | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com