Balanced fluid valve

a fluid valve and fluid flux technology, applied in the direction of fluid pressure control, flow control, instruments, etc., can solve the problem that fluid pressure regulators usually need a minimum outlet pressure, and achieve the effect of improving the independency of fluid pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

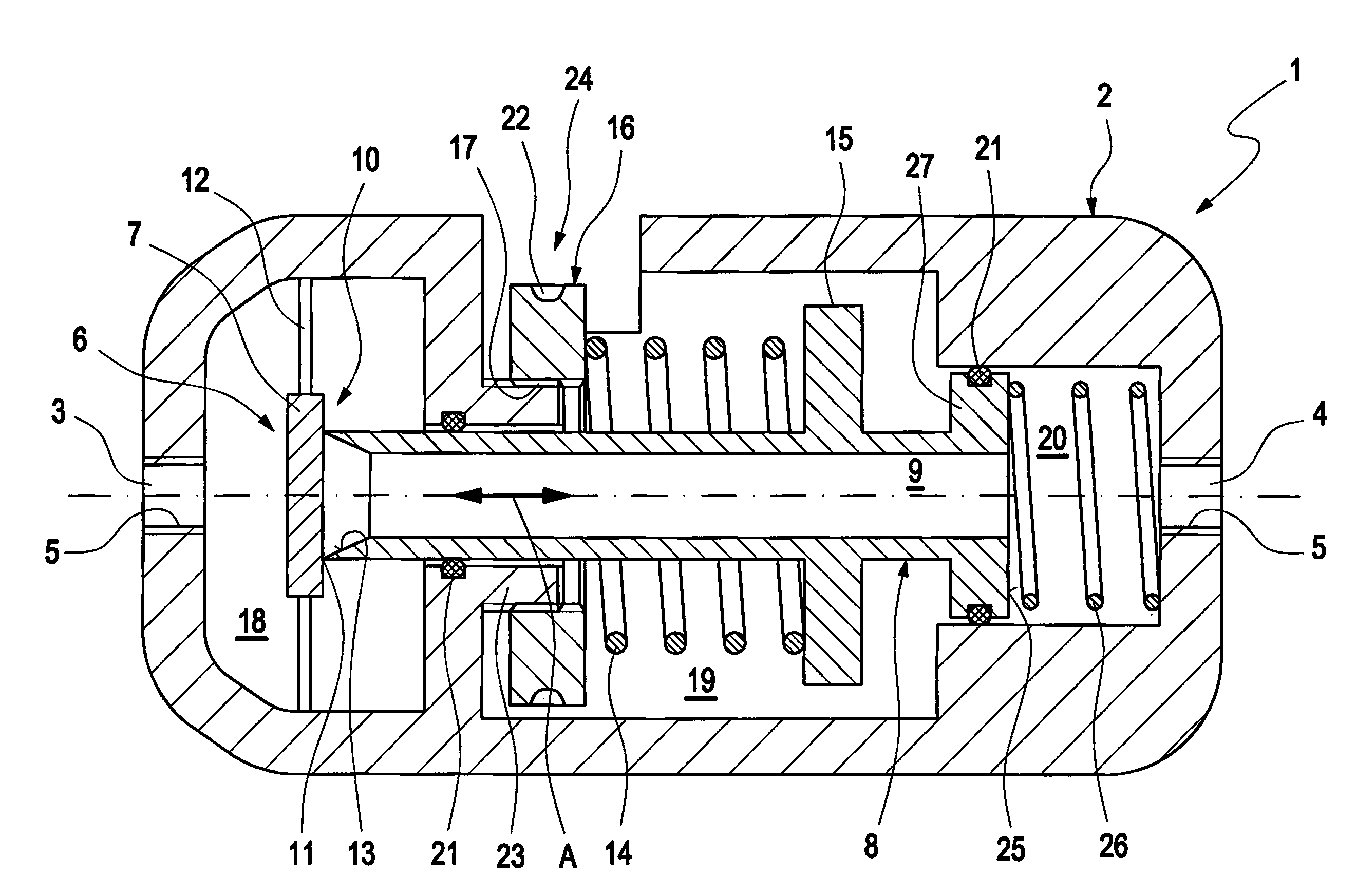

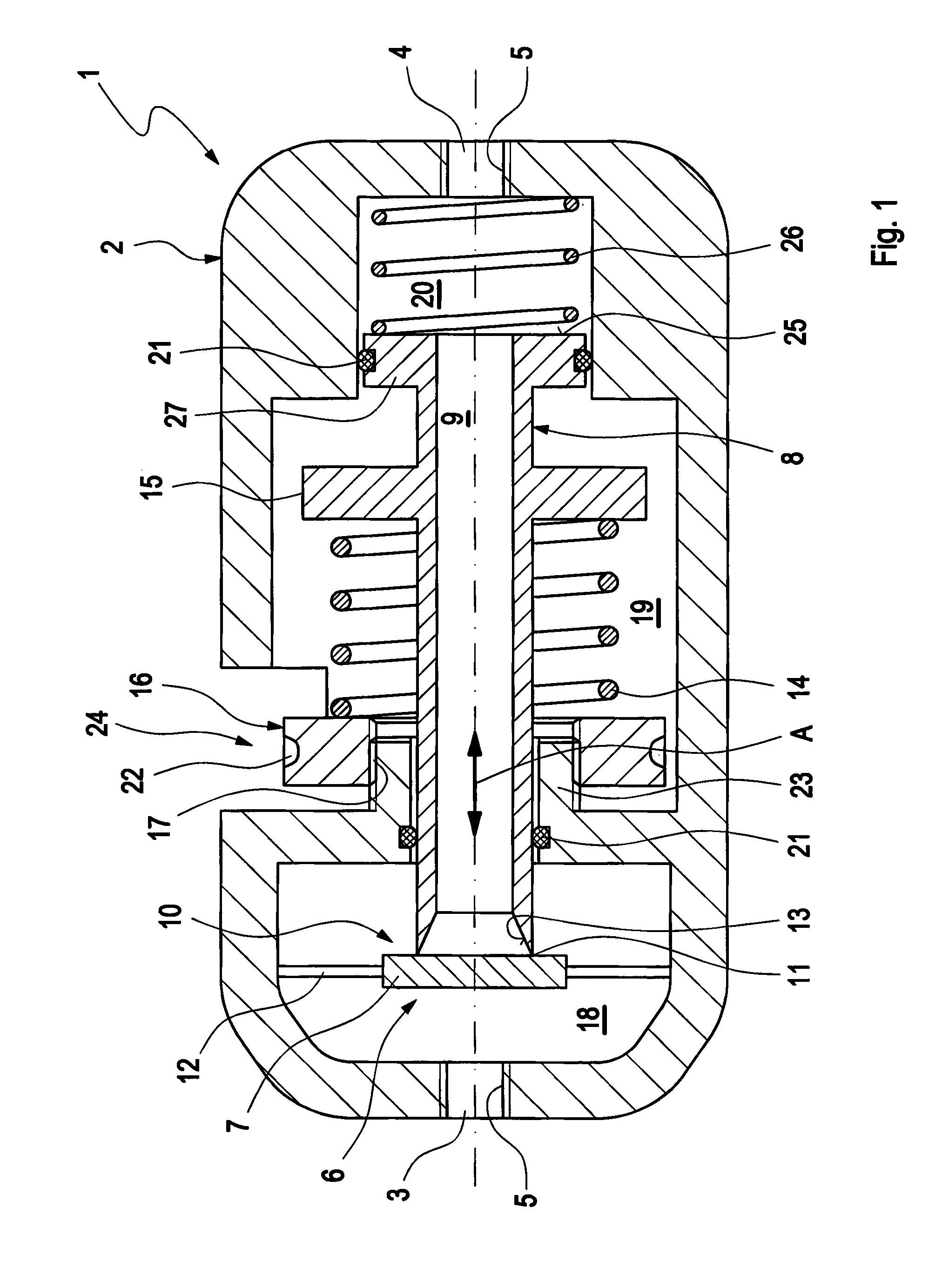

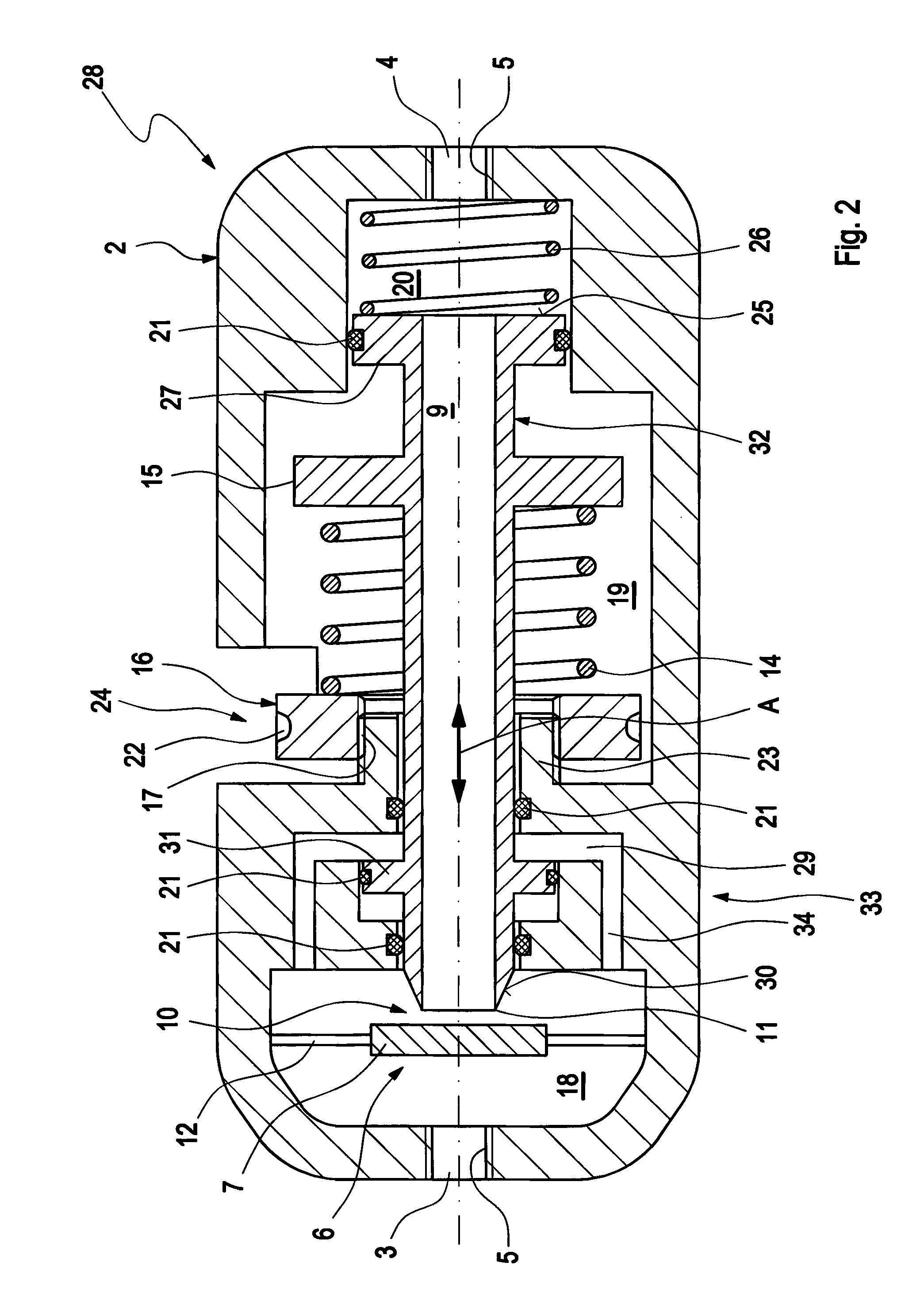

[0035]In FIG. 1, a schematical cross section through a first possible embodiment of a pressure regulator 1 is depicted. The pressure regulator 1 comprises a casing 2 with a fluid inlet port 3 and a fluid outlet port 4. Both fluid inlet port 3 and fluid outlet port 4 have an inner thread 5, so that a corresponding fluid pipe or fluid hose can be threadingly engaged in the respective fluid port 3, 4.

[0036]Within the casing 2 of the pressure regulator 1, a valve unit 6 is arranged. The valve unit 6 essentially consists of a valve seat 7 and a valve tube 8. The valve tube 8 can be moved in an axial direction (as indicated by double-headed arrow A) within the casing 2 of the pressure regulator 1.

[0037]The valve tube 8 is designed to have a hollow interior 9, forming an inner fluid line 9 through the valve tube 8. The contacting area between valve seat 7 and valve tube 8 forms the valve opening 10. If the valve tube 8 is in its leftmost position (as drawn in FIG. 1), the valve seat 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com